ডায়মন্ড টপ জিআরপি ফাইবারগ্লাস প্ল্যাটফর্ম মোল্ডেড গ্রেটিং

পণ্যের বর্ণনা

ছাঁচ স্পেসিফিকেশন টেবিল

| উচ্চতা (মিমি) | বার বেধ (মিমি উপরে/নীচে) | মেশ সাইজ (মিমি) | প্যানেলের আকার উপলব্ধ (মিমি) | ওজন (কেজি/বর্গমিটার) | খোলা হার (%) |

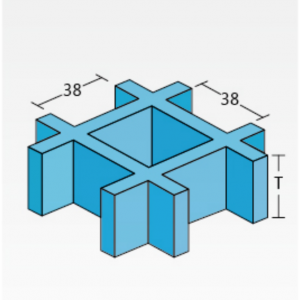

| 13 | ৬.০/৫.০ | ৩৮*৩৮ | ১২২০*২৪৪০/১২২০*৩৬৬০/১২২০*৪০০০/১০০০*৩০০০/৯২১*৩০৫৫ | 6 | 78 |

| 14 | ৬.০/৫.০ | ৩৮*৩৮ | ১২২০*২৪৪০/১২২০*৩৬৬০/১২২০*৪০০০/১০০০*৩০০০/৯২১*৩০৫৫ | ৬.৫ | 78 |

| 15 | ৬.০/৫.০ | ৩৮*৩৮ | ১২২০*২৪৪০/১২২০*৩৬৬০/১২২০*৪০০০/১০০০*৩০০০/৯২১*৩০৫৫ | 7 | 78 |

| 20 | ৬.০/৫.০ | ৩৮*৩৮ | ১২২০*২৪৪০/১২২০*৩৬৬০/১২২০*৪০০০/১২২০*৪০৩৮/১০০০*২০০০/১০০০*৩০০০/৯২১*৩০৫৫ | ৯.৮ | ৬৫ |

| ২৫ | ৬.৫/৫.০ | ৩৮*৩৮ | ১২২০*২৪৪০/১২২০*৩৬৬০/১২২০*৪০০০/১২২০*৪০৩৮/১০০০*২০০০/১০০০*৩০০০/৯১৫*৩০৫০/৯২১*৩০৫৫ | ১২.৫ | ৬৮ |

| 25 | ৭.০/৫.০ | ৩৮*৩৮ | ১০০০*৪০০০ | ১২.৫ | 68 |

| 30 | ৬.৫/৫.০ | ৩৮*৩৮ | ১২২০*২৪৪০/১২২০*৩৬৬০/১২২০*৪০০০/১২২০*৪০৩৮/১০০০*২০০০/১০০০*৩০০০/৯২১*৩০৫৫ | ১৪.৬ | ৬৮ |

| 30 | ৭.০/৫.০ | ৩৮*৩৮ | ১০০০*৪০০০/১২২০*৪০০০ | 16 | 68 |

| ৩৮ | ৬.৫/৫.০ | ৩৮*৩৮ | ১২২০*২৪৪০/১২২০*৩৬৬০/১২২০*৪০০০/১২২০*৪৯২০/১০০০*২০০০/১০০০*৩০০০/১০০০*৪০৩৮/৯২১*৩০৫৫/৯১৫*৩০৫০/১৫২৪*৩৬৬০ | ১৯.৫ | ৬৮ |

| 38 | ৭.০/৫.০ | ৩৮*৩৮ | ১০০০*৪০০০/১২২০*৪০০০ | ১৯.৫ | 68 |

| 63 | ১২.০/৮.০ | ৩৮*৩৮ | ১৫৩০*৪০০০ | 52 | 68 |

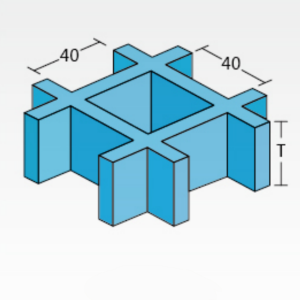

| 25 | ৬.৫/৫.০ | ৪০*৪০ | ১০০৭*৩০০৭/১০০৭*২০০৭/১০০৭*৪০৪৭/১২৪৭*৩০০৭/১২৪৭*৪০৪৭/১২০৭*৩০০৭ | ১২.৫ | ৬৭ |

| 25 | ৭.০/৫.০ | ৪০*৪০ | ১০০৭*৪০০৭ | 12 | 67 |

| 30 | ৬.৫/৫.০ | ৪০*৪০ | ১০০৭*৩০০৭/১০০৭*২০০৭/১০০৭*৪০৪৭/১২৪৭*৩০০৭/১২৪৭*৪০৪৭/১২০৭*৩০০৭ | ১৪.৬ | 67 |

| 30 | ৭.০/৫.০ | ৪০*৪০ | ১০০০*৪০০০ | 15 | 67 |

| 38 | ৭.০/৫.০ | ৪০*৪০ | ১০০৭*২০০৭/১০০৭*৩০০৭/১০০৭*৪০৪৭/১২৪৭*৩০০৭/১২৪৭*৪০৪৭/১২০৭*৩০০৭ | ১৯.২ | 67 |

| 40 | ৭.০/৫.০ | ৪০*৪০ | ১০০৭*২০০৭/১০০৭*৩০০৭/১০০৭*৪০০৭/১০০৭*৪০৪৭/১২০৭*৩০০৭/১২৪৭*৩০০৭/১২৪৭*৪০৪৭ | ১৯.৫ | ৬৭ |

| ৫০ | ৭.০/৫.০ | ৪০*৪০ | ১০০৭*২০০৭/১০০৭*৩০০৭/১০০৭*৪০৪৭/১২০৭*৩০০৭/১২৪৭*৩০০৭/১২৪৭*৪০৪৭ | ২৫.০ | ৫৮ |

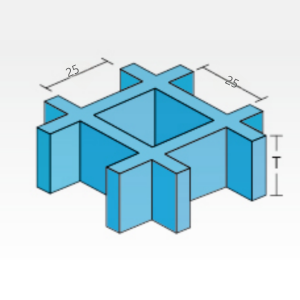

| 30 | ৭.০/৫.০ | ২৫*২৫ | ১০০০*৪০০০ | 16 | ৫৮ |

| 40 | ৭.০/৫.০ | ২৫*২৫ | ১২০০*৪০০০ | 22 | ৫৮ |

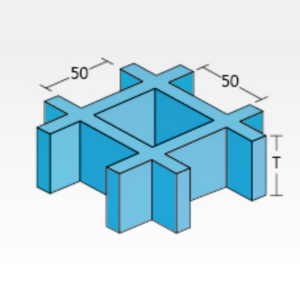

| 50 | ৮.০/৬.০ | ৫০*৫০ | ১২২০*২৪৪০/১২২০*৩৬৬০/১০০০*২০০০/১০০০*৩০০০ | 24 | 78 |

| 50 | ৭.২/৫.০ | ৫০*৫০ | ১২২০*২৪৪০/১২২০*৩৬৬০/১০০০*৪০০০/১০০০*৩০০০ | 21 | 78 |

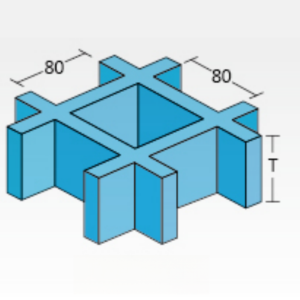

| ১৩ | ১০.০/৯.০ | ৮০*৮০ | ১৫৩০*৩৮১৭/৭৩০*১৮৭৩ | ৫.৫ | ৮১ |

| 14 | ১০.০/৯.০ | ৮০*৮০ | ১৫৩০*৩৮১৭/৭৩০*১৮৭৩ | 6 | 81 |

| 15 | ১০.০/৯.০ | ৮০*৮০ | ১৫৩০*৩৮১৭/৭৩০*১৮৭৩ | ৬.৫ | 81 |

FRP মোল্ডেড গ্রেটিং সারফেস চয়েস:

সমতল শীর্ষ

ডায়মন্ড টপ

গ্রিট সারফেস

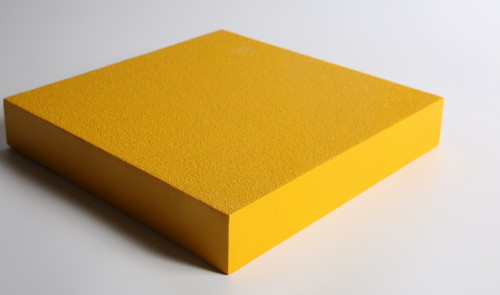

● ফ্ল্যাট টপ

ফ্ল্যাট টপ প্লেটের সাথে মোল্ডেড গ্রেটিং যোগ করা হয়েছে

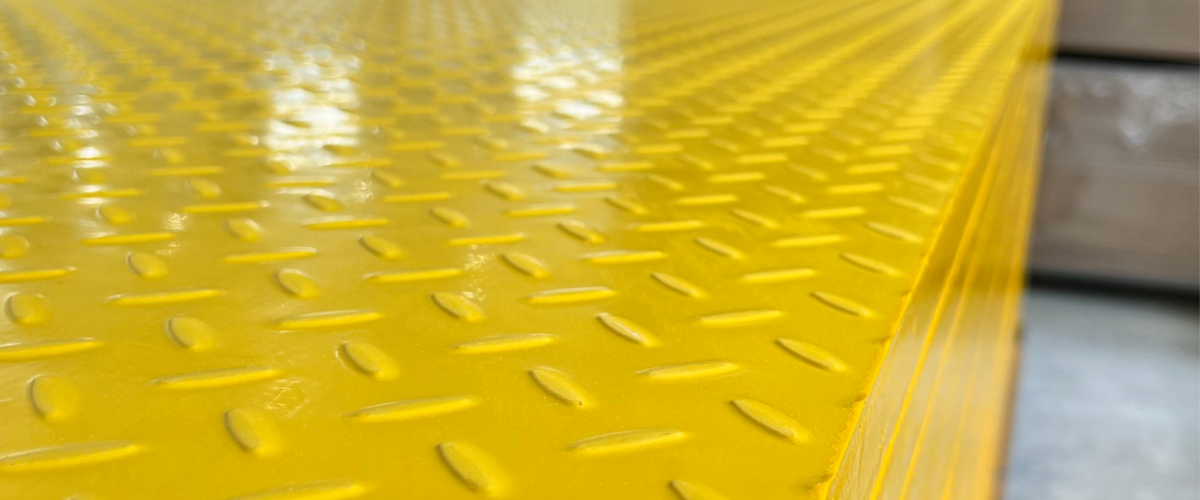

● ডায়মন্ড টপ

গ্রিপ সর্বাধিক করার জন্য উঁচু ট্রেড প্যাটার্ন সহ ফ্ল্যাট টপ প্লেট। হীরার উপরের পুরুত্ব 3 বা 5 মিমি। প্লেটের পুরুত্ব গ্রেটিংয়ের সামগ্রিক পুরুত্বকে বাড়িয়ে তোলে।

● গ্রিট টপ

৩ মিমি বা ৫ মিমি পুরুত্বের গ্রিট টপ প্লেট, প্লেটের ঘনত্ব গ্রেটিংয়ের সামগ্রিক পুরুত্বকে বাড়িয়ে তোলে

FRP রেজিন সিস্টেমের পছন্দ:

ফেনোলিক রজন (টাইপ পি): তেল শোধনাগার, ইস্পাত কারখানা এবং পিয়ার ডেকের মতো সর্বাধিক অগ্নি প্রতিরোধক এবং কম ধোঁয়া নির্গমনের প্রয়োজন এমন অ্যাপ্লিকেশনগুলির জন্য সেরা পছন্দ।

ভিনাইল এস্টার (টাইপ ভি): রাসায়নিক, বর্জ্য শোধন এবং ফাউন্ড্রি প্ল্যান্টের জন্য ব্যবহৃত কঠোর রাসায়নিক পরিবেশ সহ্য করতে পারে।

আইসোফথালিক রজন (টাইপ I): টাইপ I হল একটি প্রিমিয়াম আইসোফথালিক পলিয়েস্টার রজন। এর ভালো জারা প্রতিরোধ ক্ষমতা এবং তুলনামূলক কম খরচের কারণে এটি বেশিরভাগ ক্ষেত্রেই একটি জনপ্রিয় পছন্দ। এই ধরণের রজন সাধারণত এমন ক্ষেত্রে ব্যবহৃত হয় যেখানে কঠোর রাসায়নিকের স্প্ল্যাশ বা ছিটকে পড়ার সম্ভাবনা থাকে।

সাধারণ উদ্দেশ্য অর্থোথফালিক রজন (টাইপ O): ভিনাইল এস্টার এবং আইসোফথালিক রেজিন পণ্যের অর্থনৈতিক বিকল্প।

খাদ্য গ্রেড আইসোফথালিক রজন (টাইপ এফ): কঠোর পরিষ্কার পরিবেশে থাকা খাদ্য ও পানীয় শিল্প কারখানাগুলির জন্য আদর্শভাবে উপযুক্ত।

ইপোক্সি রজন (টাইপ ই):অন্যান্য রেজিনের সুবিধা গ্রহণ করে, খুব উচ্চ যান্ত্রিক বৈশিষ্ট্য এবং ক্লান্তি প্রতিরোধ ক্ষমতা প্রদান করে। ছাঁচের খরচ PE এবং VE এর মতো, তবে উপাদানের খরচ বেশি।

রেজিন বিকল্প নির্দেশিকা:

| রজন প্রকার | রজন বিকল্প | বৈশিষ্ট্য | রাসায়নিক প্রতিরোধ | অগ্নি প্রতিরোধক (ASTM E84) | পণ্য | কাস্টমাইজড রঙ | সর্বোচ্চ ℃ তাপমাত্রা |

| টাইপ পি | ফেনোলিক | কম ধোঁয়া এবং উচ্চতর অগ্নি প্রতিরোধ ক্ষমতা | খুব ভালো | ক্লাস ১, ৫ বা তার কম | ছাঁচে তৈরি এবং পাল্ট্রুডেড | কাস্টমাইজড রঙ | ১৫০ ℃ |

| টাইপ ভি | ভিনাইল এস্টার | উচ্চতর জারা প্রতিরোধ এবং অগ্নি প্রতিরোধক | চমৎকার | ক্লাস ১, ২৫ বা তার কম | ছাঁচে তৈরি এবং পাল্ট্রুডেড | কাস্টমাইজড রঙ | ৯৫ ℃ |

| টাইপ I | আইসোফথালিক পলিয়েস্টার | শিল্প গ্রেড জারা প্রতিরোধ এবং অগ্নি প্রতিরোধক | খুব ভালো | ক্লাস ১, ২৫ বা তার কম | ছাঁচে তৈরি এবং পাল্ট্রুডেড | কাস্টমাইজড রঙ | ৮৫ ℃ |

| টাইপ ও | অর্থো | মাঝারি জারা প্রতিরোধ এবং অগ্নি প্রতিরোধক | স্বাভাবিক | ক্লাস ১, ২৫ বা তার কম | ছাঁচে তৈরি এবং পাল্ট্রুডেড | কাস্টমাইজড রঙ | ৮৫ ℃ |

| টাইপ এফ | আইসোফথালিক পলিয়েস্টার | খাদ্য গ্রেড জারা প্রতিরোধ এবং অগ্নি প্রতিরোধক | খুব ভালো | ক্লাস ২, ৭৫ বা তার কম | ঢালাই করা | বাদামী | ৮৫ ℃ |

| টাইপ ই | ইপক্সি | চমৎকার জারা প্রতিরোধ ক্ষমতা এবং অগ্নি প্রতিরোধক | চমৎকার | ক্লাস ১, ২৫ বা তার কম | পাল্ট্রুডেড | কাস্টমাইজড রঙ | ১৮০ ℃ |

বিভিন্ন পরিবেশ এবং অ্যাপ্লিকেশন অনুসারে, বিভিন্ন রজন বেছে নেওয়া হয়েছে, আমরা কিছু পরামর্শও দিতে পারি!

কেস স্টাডিজ

ডায়মন্ড টপ এফআরপি (ফাইবারগ্লাস রিইনফোর্সড প্লাস্টিক) গ্রেটিং হল এক ধরণের গ্রেটিং যার উপরের পৃষ্ঠে একটি উঁচু হীরার প্যাটার্ন থাকে। এই নকশাটি স্ট্যান্ডার্ড ফ্ল্যাট-টপ গ্রেটিংয়ের তুলনায় উন্নত স্লিপ প্রতিরোধ ক্ষমতা প্রদান করে, যা এটিকে বিভিন্ন অ্যাপ্লিকেশনের জন্য উপযুক্ত করে তোলে যেখানে সুরক্ষা একটি উদ্বেগের বিষয়।

সাধারণ অ্যাপ্লিকেশন

◼ হাঁটার পথ বা প্ল্যাটফর্ম

শিল্প সুবিধা, বর্জ্য জল শোধনাগার, সামুদ্রিক এবং অফশোরের মতো বিভিন্ন অ্যাপ্লিকেশনের জন্য...

◼ সিঁড়ি পদধ্বনি

শিল্প, বাণিজ্যিক এবং সামুদ্রিক পরিবেশে সিঁড়ি বেয়ে ওঠার জন্য ডায়মন্ড টপ এফআরপি আদর্শ, যা চমৎকার ট্র্যাকশন প্রদান করে এবং পিছলে পড়ার ঝুঁকি কমায়।

◼ পরিখা এবং নিষ্কাশনের ঢাকনা

বিভিন্ন শিল্প ও বাণিজ্যিক পরিবেশে পরিখা এবং নিষ্কাশন চ্যানেল ঢেকে রাখার জন্য ব্যবহৃত হয়। ডায়মন্ড টপটি নিষ্কাশনের জন্য নিরাপদ হাঁটার পৃষ্ঠ প্রদান করে।

◼ র্যাম্প

পথচারী বা হালকা যানবাহনের ট্র্যাফিক এলাকায় র্যাম্পের জন্য একটি পিছলে যাওয়া-প্রতিরোধী পৃষ্ঠ প্রদান করে, যা নিরাপত্তা এবং অ্যাক্সেসযোগ্যতা বৃদ্ধি করে।

◼ পুলের ডেক এবং ভেজা জায়গা

এর অ্যান্টি-স্লিপ পৃষ্ঠ এবং জল ও রাসায়নিকের প্রতিরোধ ক্ষমতা এটিকে পুলের ডেক, ওয়াটার পার্ক এবং অন্যান্য বিনোদনমূলক জলের জায়গার জন্য উপযুক্ত উপাদান করে তোলে।

◼ খাদ্য প্রক্রিয়াকরণ সুবিধা

FRP-এর অ-ছিদ্রযুক্ত এবং ক্ষয়-প্রতিরোধী বৈশিষ্ট্য, সহজে পরিষ্কার করা যায় এমন হীরার উপরের পৃষ্ঠের সাথে মিলিত হয়ে, এটিকে খাদ্য প্রক্রিয়াকরণ প্ল্যান্টগুলিতে একটি স্বাস্থ্যকর এবং নিরাপদ মেঝে বিকল্প করে তোলে।