Anti Slip FRP /GRP Walkways Covered Grating

PRODUCT DESCRIPTION

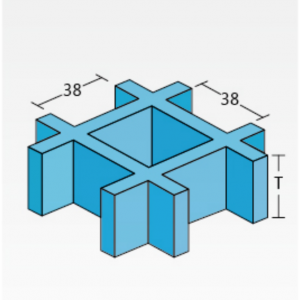

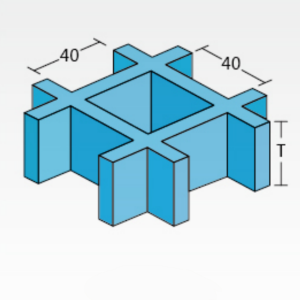

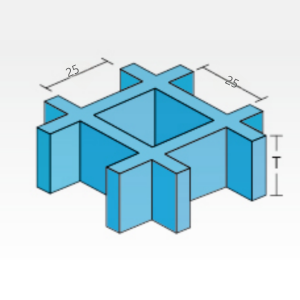

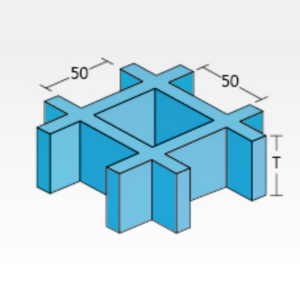

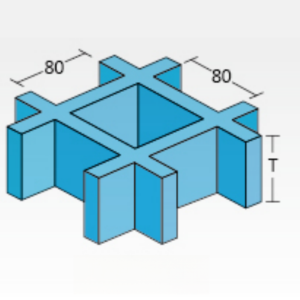

MOULDS SPECIFICATION TABLE

| HEIGHT (mm ) | BAR THICKNESS (mm TOP/BOTTOM) | MESH SIZE (MM) | PANEL SIZE AVAILABLE (MM) | WEIGHT(KG/m²) | OPEN RATE(%) |

| 13 | 6.0/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1000*3000/921*3055 | 6 | 78 |

| 14 | 6.0/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1000*3000/921*3055 | 6.5 | 78 |

| 15 | 6.0/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1000*3000/921*3055 | 7 | 78 |

| 20 | 6.0/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1220*4038/1000*2000/1000*3000/921*3055 | 9.8 | 65 |

| 25 | 6.5/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1220*4038/1000*2000/1000*3000/915*3050/921*3055 | 12.5 | 68 |

| 25 | 7.0/5.0 | 38*38 | 1000*4000 | 12.5 | 68 |

| 30 | 6.5/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1220*4038/1000*2000/1000*3000/921*3055 | 14.6 | 68 |

| 30 | 7.0/5.0 | 38*38 | 1000*4000/1220*4000 | 16 | 68 |

| 38 | 6.5/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1220*4920/1000*2000/1000*3000/1000*4038/921*3055/915*3050/1524*3660 | 19.5 | 68 |

| 38 | 7.0/5.0 | 38*38 | 1000*4000/1220*4000 | 19.5 | 68 |

| 63 | 12.0/8.0 | 38*38 | 1530*4000 | 52 | 68 |

| 25 | 6.5/5.0 | 40*40 | 1007*3007/1007*2007/1007*4047/1247*3007/1247*4047/1207*3007 | 12.5 | 67 |

| 25 | 7.0/5.0 | 40*40 | 1007*4007 | 12 | 67 |

| 30 | 6.5/5.0 | 40*40 | 1007*3007/1007*2007/1007*4047/1247*3007/1247*4047/1207*3007 | 14.6 | 67 |

| 30 | 7.0/5.0 | 40*40 | 1000*4000 | 15 | 67 |

| 38 | 7.0/5.0 | 40*40 | 1007*2007/1007*3007/1007*4047/1247*3007/1247*4047/1207*3007 | 19.2 | 67 |

| 40 | 7.0/5.0 | 40*40 | 1007*2007/1007*3007/1007*4007/1007*4047/1207*3007/1247*3007/1247*4047 | 19.5 | 67 |

| 50 | 7.0/5.0 | 40*40 | 1007*2007/1007*3007/1007*4047/1207*3007/1247*3007/1247*4047 | 25.0 | 58 |

| 30 | 7.0/5.0 | 25*25 | 1000*4000 | 16 | 58 |

| 40 | 7.0/5.0 | 25*25 | 1200*4000 | 22 | 58 |

| 50 | 8.0/6.0 | 50*50 | 1220*2440/1220*3660/1000*2000/1000*3000 | 24 | 78 |

| 50 | 7.2/5.0 | 50*50 | 1220*2440/1220*3660/1000*4000/1000*3000 | 21 | 78 |

| 13 | 10.0/9.0 | 80*80 | 1530*3817/730*1873 | 5.5 | 81 |

| 14 | 10.0/9.0 | 80*80 | 1530*3817/730*1873 | 6 | 81 |

| 15 | 10.0/9.0 | 80*80 | 1530*3817/730*1873 | 6.5 | 81 |

FRP molded grating surface choics:

Flat top

Diamond Top

Grit Surfacce

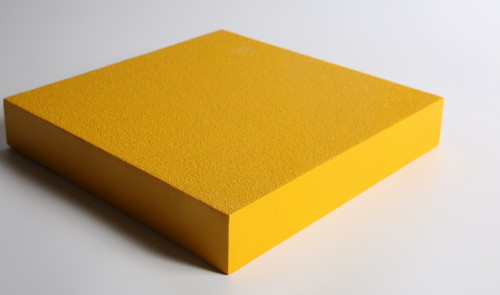

● Flat Top

Molded grating added with flat top plate

● Diamond Top

Flat top plate with raised tread pattern to maxmise grip. diamond top thicknesss 3 or 5 mm. plate thickness adds to the overall thickness of grating

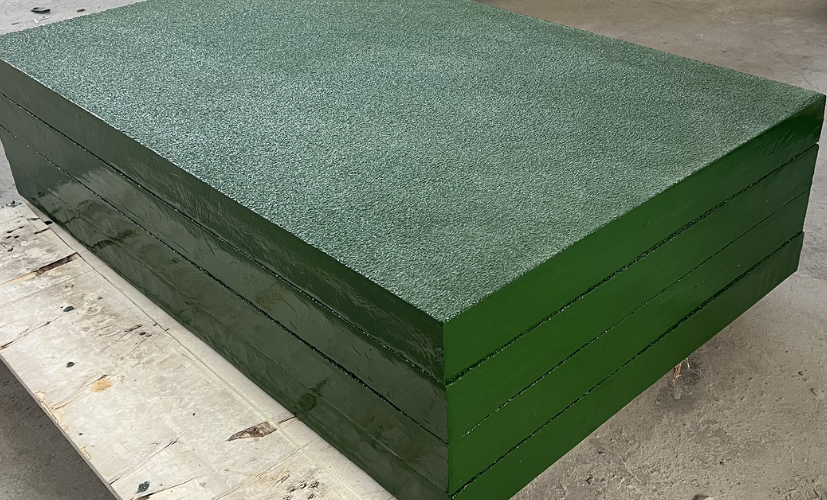

● Grit Top

Grit top plate with thickness 3mm or 5mm, plate thickeness adds to the overall thickness of the grating

FRP Resins Systems Choices:

Phenolic resin (Type P): The best choice for applications requiring max fire retardant and low smoke emissions such as oil refineries, steel factories, and pier decks.

Vinyl Ester (Type V): withstand the strict chemical environments used for chemical, waste treatment, and foundry plants.

Isophthalic resin (Type I): Type I is a premium isophthalic polyester resin. It is a popular choice for most applications due to its good corrosion resistance properties and relative low cost. This type of resin is most commonly used in applications where there is a possibility of a splash or spill of harsh chemicals.

General Purpose Orthothphalic resin (Type O): economic alternatives to vinyl ester and isophthalic resins products.

Food Grade Isophthalic resin (Type F): Ideally suitable for food and beverage industry factories which are exposed to strict clean environments.

Epoxy Resin(Type E):offer very high mechanical properties and fatigue resistance, taking the advantages of other resins. Mold costs are similar to PE and VE, but material costs are higher.

Resins options guide:

| Resin Type | Resin Option | Properties | Chemmical Resistance | Fire Retardant(ASTM E84) | Products | Bespoke Colors | Max ℃ Temp |

| Type P | Phenolic | Low Smoke and Superior Fire Resistance | Very Good | Class 1, 5 or less | Molded and Pultruded | Bespoke Colors | 150℃ |

| Type V | Vinyl Ester | Superior Corrosion Resistance and Fire Retardant | Excellent | Class 1, 25 or less | Molded and Pultruded | Bespoke Colors | 95℃ |

| Type I | Isophthalic polyester | Industrial Grade Corrosion Resistance and Fire Retardant | Very Good | Class 1, 25 or less | Molded and Pultruded | Bespoke Colors | 85℃ |

| Type O | Ortho | Moderate Corrosion Resistance and Fire Retardant | Normal | Class 1, 25 or less | Molded and Pultruded | Bespoke Colors | 85℃ |

| Type F | Isophthalic polyester | Food Grade Corrosion Resistance and Fire Retardant | Very Good | Class 2, 75 or less | Molded | Brown | 85℃ |

| Type E | Epoxy | Excellent corrosion resistance and fire retardant | Excellent | Class 1, 25 or less | Pultruded | Bespoke Colors | 180℃ |

According to the different environments and applications, chosen different resins, we also could provide some advices!

CASE STUDIES

Our FRP (Fiberglass Reinforced Plastic) Covered Grating combines structural strength with superior chemical resistance, making it an ideal choice for harsh environments.

The cover panel delivers in material, structure, and functionality, offering superior safety, durability, and lifecycle cost savings for mission-critical industrial applications.

Typical Applications

◼ Chemical processing plants

◼ Offshore platforms & marine facilities

◼ Wastewater treatment plants

◼ Food & pharmaceutical facilities

◼ Electrical substations

◼ Walkways & safety platforms