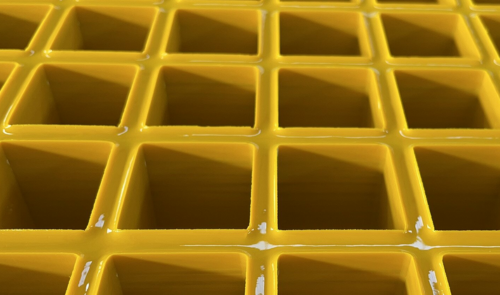

GRP/FRP Fiberglass Walkway Moulded Grating

PRODUCT DESCRIPTION

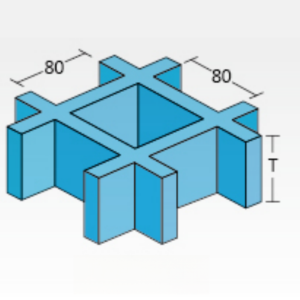

MOULDS SPECIFICATION TABLE

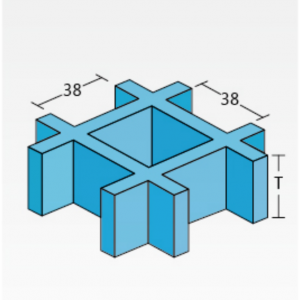

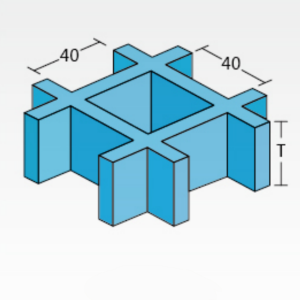

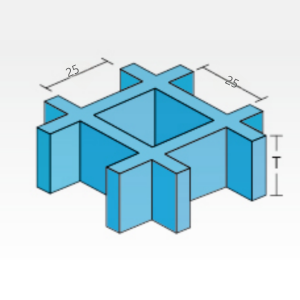

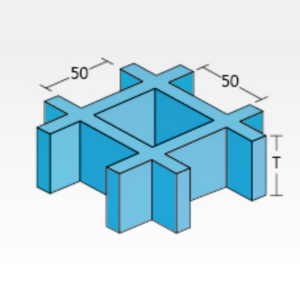

| HEIGHT (mm ) | BAR THICKNESS (mm TOP/BOTTOM) | MESH SIZE (MM) | PANEL SIZE AVAILABLE (MM) | WEIGHT(KG/m²) | OPEN RATE(%) |

| 13 | 6.0/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1000*3000/921*3055 | 6 | 78 |

| 14 | 6.0/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1000*3000/921*3055 | 6.5 | 78 |

| 15 | 6.0/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1000*3000/921*3055 | 7 | 78 |

| 20 | 6.0/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1220*4038/1000*2000/1000*3000/921*3055 | 9.8 | 65 |

| 25 | 6.5/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1220*4038/1000*2000/1000*3000/915*3050/921*3055 | 12.5 | 68 |

| 25 | 7.0/5.0 | 38*38 | 1000*4000 | 12.5 | 68 |

| 30 | 6.5/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1220*4038/1000*2000/1000*3000/921*3055 | 14.6 | 68 |

| 30 | 7.0/5.0 | 38*38 | 1000*4000/1220*4000 | 16 | 68 |

| 38 | 6.5/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1220*4920/1000*2000/1000*3000/1000*4038/921*3055/915*3050/1524*3660 | 19.5 | 68 |

| 38 | 7.0/5.0 | 38*38 | 1000*4000/1220*4000 | 19.5 | 68 |

| 63 | 12.0/8.0 | 38*38 | 1530*4000 | 52 | 68 |

| 25 | 6.5/5.0 | 40*40 | 1007*3007/1007*2007/1007*4047/1247*3007/1247*4047/1207*3007 | 12.5 | 67 |

| 25 | 7.0/5.0 | 40*40 | 1007*4007 | 12 | 67 |

| 30 | 6.5/5.0 | 40*40 | 1007*3007/1007*2007/1007*4047/1247*3007/1247*4047/1207*3007 | 14.6 | 67 |

| 30 | 7.0/5.0 | 40*40 | 1000*4000 | 15 | 67 |

| 38 | 7.0/5.0 | 40*40 | 1007*2007/1007*3007/1007*4047/1247*3007/1247*4047/1207*3007 | 19.2 | 67 |

| 40 | 7.0/5.0 | 40*40 | 1007*2007/1007*3007/1007*4007/1007*4047/1207*3007/1247*3007/1247*4047 | 19.5 | 67 |

| 50 | 7.0/5.0 | 40*40 | 1007*2007/1007*3007/1007*4047/1207*3007/1247*3007/1247*4047 | 25.0 | 58 |

| 30 | 7.0/5.0 | 25*25 | 1000*4000 | 16 | 58 |

| 40 | 7.0/5.0 | 25*25 | 1200*4000 | 22 | 58 |

| 50 | 8.0/6.0 | 50*50 | 1220*2440/1220*3660/1000*2000/1000*3000 | 24 | 78 |

| 50 | 7.2/5.0 | 50*50 | 1220*2440/1220*3660/1000*4000/1000*3000 | 21 | 78 |

| 13 | 10.0/9.0 | 80*80 | 1530*3817/730*1873 | 5.5 | 81 |

| 14 | 10.0/9.0 | 80*80 | 1530*3817/730*1873 | 6 | 81 |

| 15 | 10.0/9.0 | 80*80 | 1530*3817/730*1873 | 6.5 | 81 |

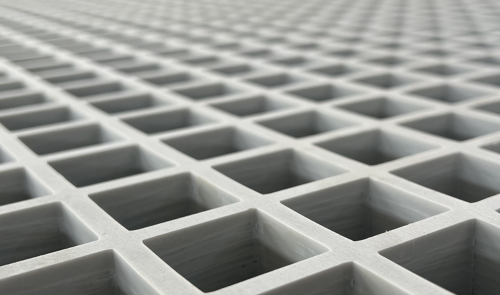

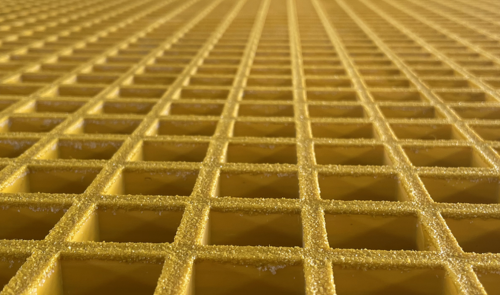

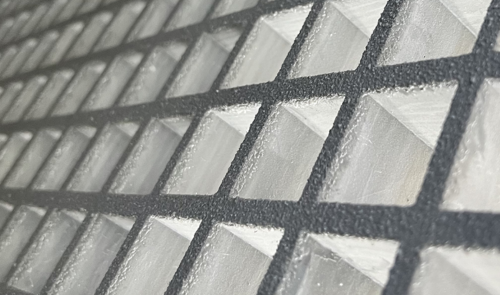

FRP molded grating surface choics:

Flat Top

Standard Grit

Fine Grit

Concave Finish

● Flat Top Molded grating ground to a smooth flat surface

●Standard Grit Standard grit for non slip protection

●Cancave Surface Natural finish with slight concave profile on load bars

● Fine grit Surface A fine grit surface finish which requires the surface to be ground smooth to remove the concave finish before applying fine sand.

FRP Resins Systems Choices:

Phenolic resin (Type P): The best choice for applications requiring max fire retardant and low smoke emissions such as oil refineries, steel factories, and pier decks.

Vinyl Ester (Type V): withstand the strict chemical environments used for chemical, waste treatment, and foundry plants.

Isophthalic resin (Type I): Type I is a premium isophthalic polyester resin. It is a popular choice for most applications due to its good corrosion resistance properties and relative low cost. This type of resin is most commonly used in applications where there is a possibility of a splash or spill of harsh chemicals.

General Purpose Orthothphalic resin (Type O): economic alternatives to vinyl ester and isophthalic resins products.

Food Grade Isophthalic resin (Type F): Ideally suitable for food and beverage industry factories which are exposed to strict clean environments.

Epoxy Resin(Type E):offer very high mechanical properties and fatigue resistance, taking the advantages of other resins. Mold costs are similar to PE and VE, but material costs are higher.

Resins options guide:

| Resin Type | Resin Option | Properties | Chemmical Resistance | Fire Retardant(ASTM E84) | Products | Bespoke Colors | Max ℃ Temp |

| Type P | Phenolic | Low Smoke and Superior Fire Resistance | Very Good | Class 1, 5 or less | Molded and Pultruded | Bespoke Colors | 150℃ |

| Type V | Vinyl Ester | Superior Corrosion Resistance and Fire Retardant | Excellent | Class 1, 25 or less | Molded and Pultruded | Bespoke Colors | 95℃ |

| Type I | Isophthalic polyester | Industrial Grade Corrosion Resistance and Fire Retardant | Very Good | Class 1, 25 or less | Molded and Pultruded | Bespoke Colors | 85℃ |

| Type O | Ortho | Moderate Corrosion Resistance and Fire Retardant | Normal | Class 1, 25 or less | Molded and Pultruded | Bespoke Colors | 85℃ |

| Type F | Isophthalic polyester | Food Grade Corrosion Resistance and Fire Retardant | Very Good | Class 2, 75 or less | Molded | Brown | 85℃ |

| Type E | Epoxy | Excellent corrosion resistance and fire retardant | Excellent | Class 1, 25 or less | Pultruded | Bespoke Colors | 180℃ |

According to the different environments and applications, chosen different resins, we also could provide some advices!

CASE STUDIES

SINOGRATES@FRP grating is made from high strength fiberglass and premium resin, it is ideal for industrial, marine, and public envoiromentss where safety, durabilty and corrosion resistance, could do a excellent work as below :

Anti-Slip Design : The concave surface enhance traction, reducing risk in wet, oily or icy conditions.

High Drainage efficiency: Channels liguids quickly, minimizing standing water and debris buidup.

Where the concave surface frp grating should be used

Industrial: Chemical plants, oil platforms, wastewater treatment walkways.

Marine: Docks, ship decks, offshore platforms.

Public Infrastructure: Bridges, pedestrian pathways, parking garages.

Specialized: Food processing facilities, cold storage, mining operations.