GRP FIBERGLASS MICRO MESH GRATING

PRODUCT DESCRIPTION

MOULDS SPECIFICATION TABLE

| HEIGHT (mm ) | BAR THICKNESS (mm TOP/BOTTOM) | MESH SIZE (MM) | PANEL SIZE AVAILABLE (MM) | WEIGHT(KG/m²) | OPEN RATE(%) |

| 30 | 7.0/5.0 | 11*11 | 1000*4000 | 21.0 | / |

| 25 | 6.5/5.0 | 19*19 | 1220*2440/1220*3660 double layer/1000*2000/1000*3000/921*3055/1220*3660 | 16.8 | 30 |

| 30 | 6.5/5.0 | 19*19 | 1220*2440/1220*3660/1220*4000/1000*2000/1000*3000/915*3050 | 18.8 | 30 |

| 38 | 6.5/5.0 | 19*19 | 1220*2440/1220*3660/1220*4000/1000*2000/1000*3000/915*3050 | 23.5 | 30 |

| 38 | 6.5/5.0 | 19*19 | 1220*3660 double layer | 22.0 | 30 |

| 60 | 6.5/5.0 | 19*19 | 1220*3660 double layer | 35.0 | 30 |

| 14 | 7.0/5.0 | 20*20 | 1247*4007 | 10.5 | 30 |

| 22 | 7.0/5.0 | 20*20 | 1247*4047/1527*4047 | 16.0 | 30 |

| 25 | 6.5/5.0 | 20*20 | 1007*2007/1007*3007/1007*4047/1207*3007/1247*3007/1247*4047 | 17.8 | 30 |

| 30 | 7.0/5.0 | 20*20 | 1007*4047/1247*4047 | 19.5 | 30 |

| 38 | 7.0/5.0 | 20*20 | 1007*4047 | 23.0 | 30 |

| 40 | 7.0/5.0 | 20*20 | 1007*2007/1007*3007/1007*4047/1207*3007/1247*3007/1247*4047 | 23.8 | 30 |

FRP molded grating surface choics:

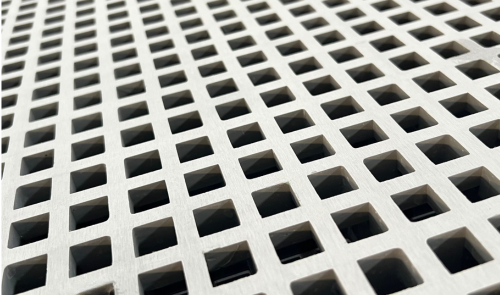

Flat Top

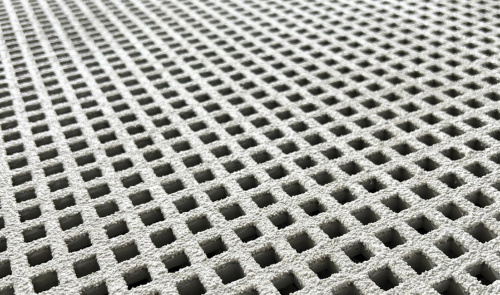

Standard Grit

Concave Finish

● Flat Top Molded grating ground to a smooth flat surface

●Standard Grit Standard grit for non slip protection

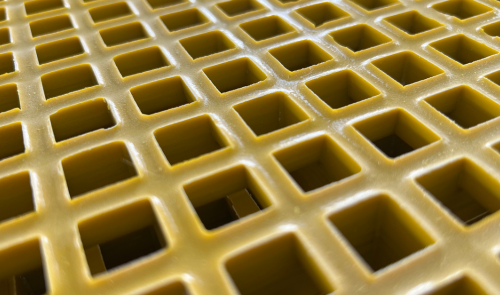

●Cancave Surface Natural finish with slight concave profile on load bars

FRP Resins Systems Choices:

Phenolic resin (Type P): The best choice for applications requiring max fire retardant and low smoke emissions such as oil refineries, steel factories, and pier decks.

Vinyl Ester (Type V): withstand the strict chemical environments used for chemical, waste treatment, and foundry plants.

Isophthalic resin (Type I): Type I is a premium isophthalic polyester resin. It is a popular choice for most applications due to its good corrosion resistance properties and relative low cost. This type of resin is most commonly used in applications where there is a possibility of a splash or spill of harsh chemicals.

General Purpose Orthothphalic resin (Type O): economic alternatives to vinyl ester and isophthalic resins products.

Food Grade Isophthalic resin (Type F): Ideally suitable for food and beverage industry factories which are exposed to strict clean environments.

Epoxy Resin(Type E):offer very high mechanical properties and fatigue resistance, taking the advantages of other resins. Mold costs are similar to PE and VE, but material costs are higher.

Resins options guide:

| Resin Type | Resin Option | Properties | Chemmical Resistance | Fire Retardant(ASTM E84) | Products | Bespoke Colors | Max ℃ Temp |

| Type P | Phenolic | Low Smoke and Superior Fire Resistance | Very Good | Class 1, 5 or less | Molded and Pultruded | Bespoke Colors | 150℃ |

| Type V | Vinyl Ester | Superior Corrosion Resistance and Fire Retardant | Excellent | Class 1, 25 or less | Molded and Pultruded | Bespoke Colors | 95℃ |

| Type I | Isophthalic polyester | Industrial Grade Corrosion Resistance and Fire Retardant | Very Good | Class 1, 25 or less | Molded and Pultruded | Bespoke Colors | 85℃ |

| Type O | Ortho | Moderate Corrosion Resistance and Fire Retardant | Normal | Class 1, 25 or less | Molded and Pultruded | Bespoke Colors | 85℃ |

| Type F | Isophthalic polyester | Food Grade Corrosion Resistance and Fire Retardant | Very Good | Class 2, 75 or less | Molded | Brown | 85℃ |

| Type E | Epoxy | Excellent corrosion resistance and fire retardant | Excellent | Class 1, 25 or less | Pultruded | Bespoke Colors | 180℃ |

According to the different environments and applications, chosen different resins, we also could provide some advices!

Products capacities test laboratory:

The meticulous experimental equipment for FRP pultruded profiles and FRP molded gratings ,such as flexural tests,tensile tests,compression tests, and destructive tests. According to customers’ requirements,we will conduct performances & capacities tests on FRP products ,keeping the records to guarantee the quality stability for long-term.meanwhile, We are always researching & developing innovative products with testing the reliability of FRP product performance. We can ensure that the quality can satisfy customers’ requirements stably to avoid unnecessary after-sales problems.

SINOGRATES@FRP MOLDED GRATING

•Light

•Insulation

•Chemical resistance

•Fire retardant

•Anti-slip surfaces

•Convenient for installation

•Low maintenance cost

•UV protection

•Dual strength

SINOGRATES@FRP grating is a hand lay-up composite of unsaturated resin and continuous fiberglass roving that is thoroughly wetted out and woven through an open mould.Our FRP grating is composed of 30%-35% fiberglass roving and 40% unsaturated resin ,Meanwhile,fire retardant blockers (ASTM-E84 )and UV protection blockers will be added to mixed materials during manufacturing.

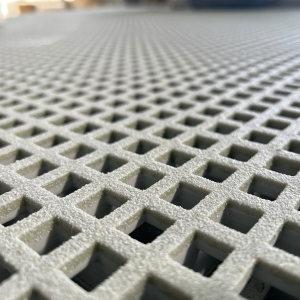

FRP (Fiberglass Reinforced Plastic) MINI grating is a lightweight, corrosion-resistant grating with a smaller mesh size and shallower depth compared to standard FRP grating.

Its primary uses include:

Light-Duty Walkways such as Ideal for pedestrian areas with low to moderate foot traffic, such as catwalks, platforms, or maintenance pathways

Drainage Covers: Used in drainage systems, trenches, or channels where smaller openings prevent debris accumulation

Architectural Applications: Decorative or functional uses in landscaping, stair treads, or sunshades due to its aesthetic appeal and customization options.