Uhi ʻia nā alanui hele wāwae Anti Slip FRP / GRP

HOIKE HUA

PAPA PALAPALA OLA

| HEIGHT (mm ) | KA MANANOA PAA (mm luna/lalo) | NUI MESH (MM) | LOA KA NUI PANEL (MM) | NUI (KG/m²) | UKU HAHA(%) |

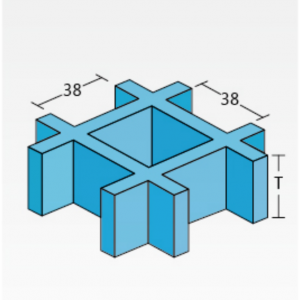

| 13 | 6.0/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1000*3000/921*3055 | 6 | 78 |

| 14 | 6.0/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1000*3000/921*3055 | 6.5 | 78 |

| 15 | 6.0/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1000*3000/921*3055 | 7 | 78 |

| 20 | 6.0/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1220*4038/1000*2000/1000*3000/921*3055 | 9.8 | 65 |

| 25 | 6.5/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1220*4038/1000*2000/1000*3000/915*3050/921*3055 | 12.5 | 68 |

| 25 | 7.0/5.0 | 38*38 | 1000*4000 | 12.5 | 68 |

| 30 | 6.5/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1220*4038/1000*2000/1000*3000/921*3055 | 14.6 | 68 |

| 30 | 7.0/5.0 | 38*38 | 1000*4000/1220*4000 | 16 | 68 |

| 38 | 6.5/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1220*4920/1000*2000/1000*3000/1000*4038/921*3055/915*3050/1524*366 | 19.5 | 68 |

| 38 | 7.0/5.0 | 38*38 | 1000*4000/1220*4000 | 19.5 | 68 |

| 63 | 12.0/8.0 | 38*38 | 1530*4000 | 52 | 68 |

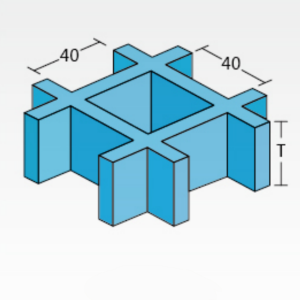

| 25 | 6.5/5.0 | 40*40 | 1007*3007/1007*2007/1007*4047/1247*3007/1247*4047/1207*3007 | 12.5 | 67 |

| 25 | 7.0/5.0 | 40*40 | 1007*4007 | 12 | 67 |

| 30 | 6.5/5.0 | 40*40 | 1007*3007/1007*2007/1007*4047/1247*3007/1247*4047/1207*3007 | 14.6 | 67 |

| 30 | 7.0/5.0 | 40*40 | 1000*4000 | 15 | 67 |

| 38 | 7.0/5.0 | 40*40 | 1007*2007/1007*3007/1007*4047/1247*3007/1247*4047/1207*3007 | 19.2 | 67 |

| 40 | 7.0/5.0 | 40*40 | 1007*2007/1007*3007/1007*4007/1007*4047/1207*3007/1247*3007/1247*4047 | 19.5 | 67 |

| 50 | 7.0/5.0 | 40*40 | 1007*2007/1007*3007/1007*4047/1207*3007/1247*3007/1247*4047 | 25.0 | 58 |

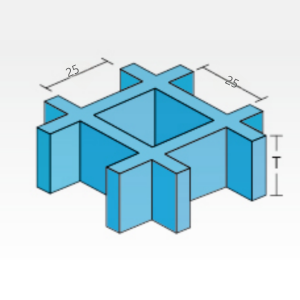

| 30 | 7.0/5.0 | 25*25 | 1000*4000 | 16 | 58 |

| 40 | 7.0/5.0 | 25*25 | 1200*4000 | 22 | 58 |

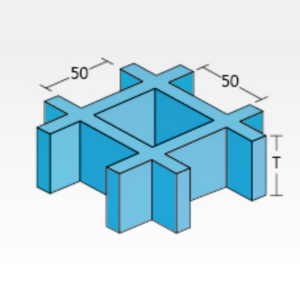

| 50 | 8.0/6.0 | 50*50 | 1220*2440/1220*3660/1000*2000/1000*3000 | 24 | 78 |

| 50 | 7.2/5.0 | 50*50 | 1220*2440/1220*3660/1000*4000/1000*3000 | 21 | 78 |

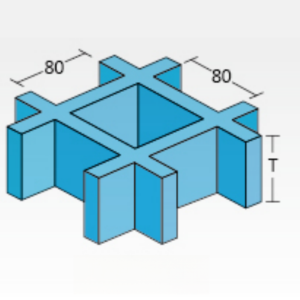

| 13 | 10.0/9.0 | 80*80 | 1530*3817/730*1873 | 5.5 | 81 |

| 14 | 10.0/9.0 | 80*80 | 1530*3817/730*1873 | 6 | 81 |

| 15 | 10.0/9.0 | 80*80 | 1530*3817/730*1873 | 6.5 | 81 |

FRP molded grating surface choics:

luna pālahalaha

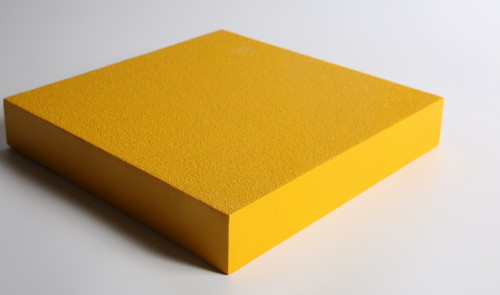

Diamond Top

ʻili ʻili

● Maluna Papa

Hoʻohui ʻia ka ʻuala me ka pā pālahalaha

● Diamond Top

ʻO ka pā pālahalaha me ke ʻano hehi hoʻokiʻekiʻe e hoʻonui i ka paʻa. daimana ka mānoanoa luna 3 a i ʻole 5 mm. hoʻonui ka mānoanoa pā i ka mānoanoa holoʻokoʻa o ka mānoanoa

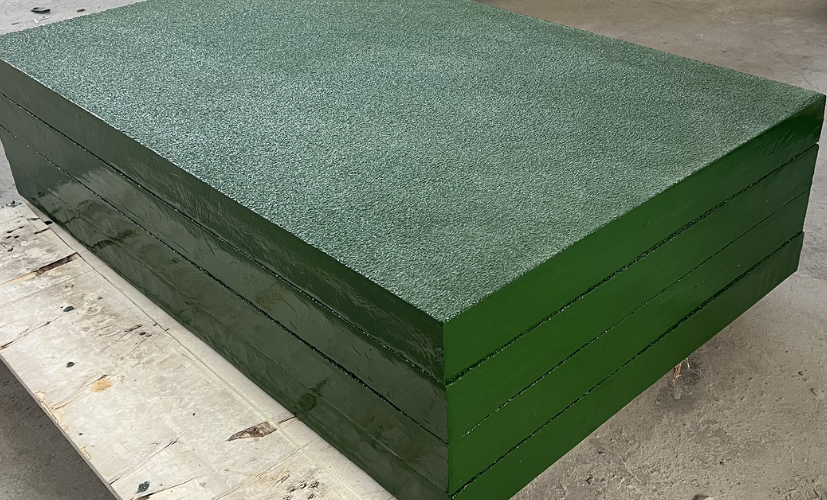

● ʻO ke kiʻekiʻe kiʻekiʻe

ʻO ka pā ma luna me ka mānoanoa 3mm a i ʻole 5mm, hoʻohui ka mānoanoa pā i ka mānoanoa holoʻokoʻa o ka pā.

Nā koho ʻōnaehana FRP Resins:

Phenolic resin (ʻAno P): ʻO ke koho maikaʻi loa no nā noi e koi ana i ka nui o ke ahi ahi a me ka uahi haʻahaʻa e like me nā mea hoʻoheheʻe aila, nā hale hana kila, a me nā deck pier.

Vinyl Ester (ʻAno V): pale i nā kaiaola kemika ikaika i hoʻohana ʻia no ka lāʻau kemika, ka hoʻomaʻemaʻe ʻōpala, a me nā mea kanu hana.

Isophthalic resin (ʻano I): ʻO ke ʻano I he isophthalic polyester resin. He koho kaulana ia no ka hapa nui o nā noi ma muli o kāna mau waiwai kūpaʻa corrosion maikaʻi a me ke kumu kūʻai haʻahaʻa. Hoʻohana maʻamau ʻia kēia ʻano resin i nā noi kahi e hiki ai ke paʻi ʻia a i ʻole ke kahe ʻana o nā kemika koʻikoʻi.

ʻO ka resin orthothphalic kumu nui (ʻano O): nā mea ʻokoʻa hoʻokele waiwai i nā huahana vinyl ester a me isophthalic resins.

ʻAi ʻAi Isophthalic resin (ʻAno F): He kūpono no nā hale ʻoihana meaʻai a me nā mea inu e ʻike ʻia i nā wahi maʻemaʻe maʻemaʻe.

Epoxy Resin (ʻAno E):hāʻawi i nā waiwai mechanical kiʻekiʻe a me ke kūpaʻa luhi, e lawe i nā pono o nā resins ʻē aʻe. Ua like nā kumukūʻai mold me PE a me VE, akā ʻoi aku ka kiʻekiʻe o nā kumukūʻai.

Nā alakaʻi koho resins:

| ʻAno Resin | Koho Resin | Waiwai | Kūʻē Kemika | Paʻa ahi (ASTM E84) | Nā huahana | Nā waihoʻoluʻu i koho ʻia | Max ℃ Temp |

| ʻAno P | Phenolic | ʻO ka uahi haʻahaʻa a me ke kūpaʻa ahi kiʻekiʻe | Maikaʻi loa | Papa 1, 5 a emi mai | Molded and Pultruded | Nā waihoʻoluʻu i koho ʻia | 150 ℃ |

| ʻAno V | Vinyl Ester | ʻOi aku ka pale ʻana i ka ʻino a me ke ahi | maikaʻi loa | Papa 1, 25 a emi mai | Molded and Pultruded | Nā waihoʻoluʻu i koho ʻia | 95 ℃ |

| ʻAno I | Isophthalic polyester | ʻO ke kūʻē ʻana i ke ahi a me ke ahi | Maikaʻi loa | Papa 1, 25 a emi mai | Molded and Pultruded | Nā waihoʻoluʻu i koho ʻia | 85 ℃ |

| ʻAno O | ʻO Ortho | ʻO ke kūpaʻa ʻino a me ka pale ahi | Maʻamau | Papa 1, 25 a emi mai | Molded and Pultruded | Nā waihoʻoluʻu i koho ʻia | 85 ℃ |

| ʻAno F | Isophthalic polyester | ʻAi ʻAi ʻAi ʻAi a me ke ahi | Maikaʻi loa | Papa 2, 75 a emi mai | Hana ʻia | Palaunu | 85 ℃ |

| ʻAno E | Epoxy | ʻOi aku ka pale ʻana i ka corrosion a me ka pale ahi | maikaʻi loa | Papa 1, 25 a emi mai | Pultruded | Nā waihoʻoluʻu i koho ʻia | 180 ℃ |

Wahi a nā kaiapuni like ʻole a me nā noi, koho ʻia nā resins ʻokoʻa, hiki iā mākou ke hāʻawi i kekahi mau ʻōlelo aʻoaʻo!

HAAWINA HELUHELU

Hoʻohui ʻia kā mākou FRP (Fiberglass Reinforced Plastic) Covered Grating i ka ikaika kūkulu me ke kūpaʻa kemika ʻoi aku ka maikaʻi, e lilo ia i koho kūpono no nā kaiapuni paʻakikī.

Hāʻawi ka papa uhi i nā mea waiwai, ka hoʻolālā, a me nā hana, e hāʻawi ana i ka palekana ʻoi aku ka maikaʻi, ka lōʻihi, a me ka mālama ʻana i ke kumukūʻai ola no nā noi ʻoihana koʻikoʻi.

Nā noi maʻamau

◼ Nā mea kanu hoʻoponopono kemika

◼ Nā paepae waho a me nā lako kai

◼ Mea kanu hoʻomaʻemaʻe wai

◼ Meaʻai a me nā hale hana lāʻau

◼ ʻO nā pahu uila

◼ Nā ala hele a me nā paepae palekana