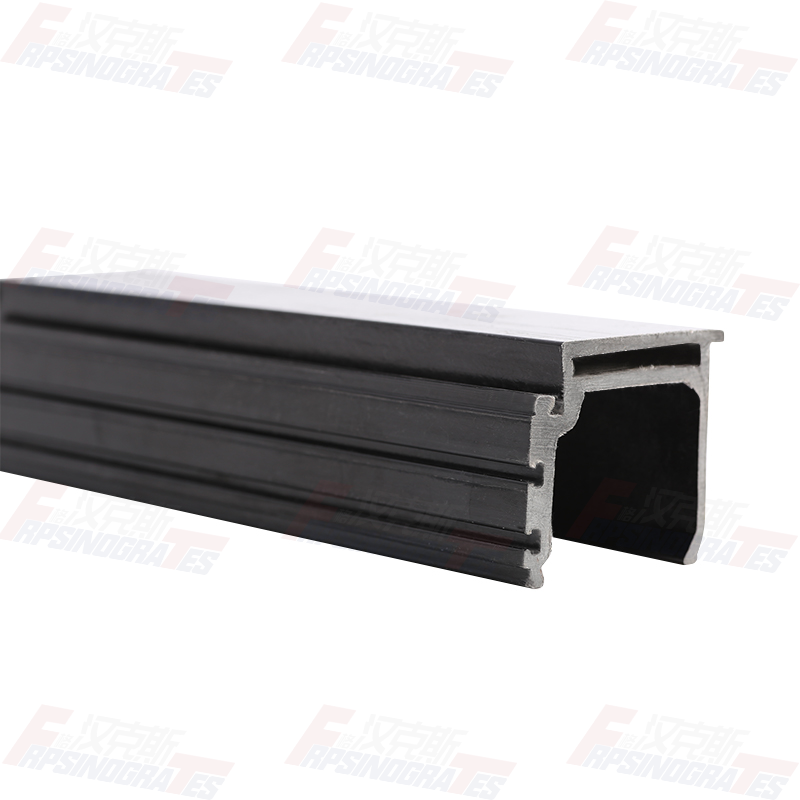

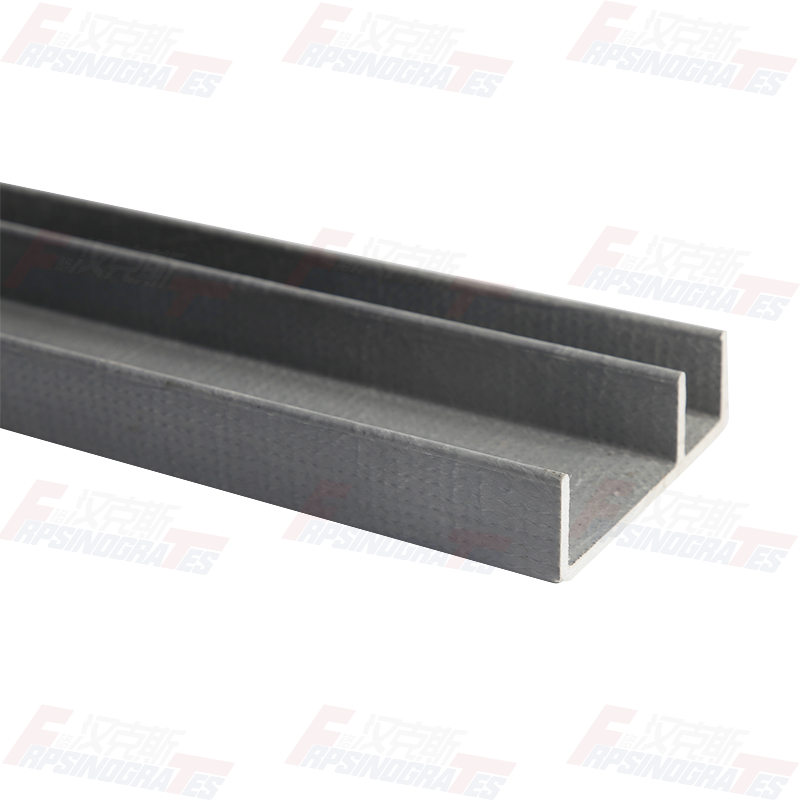

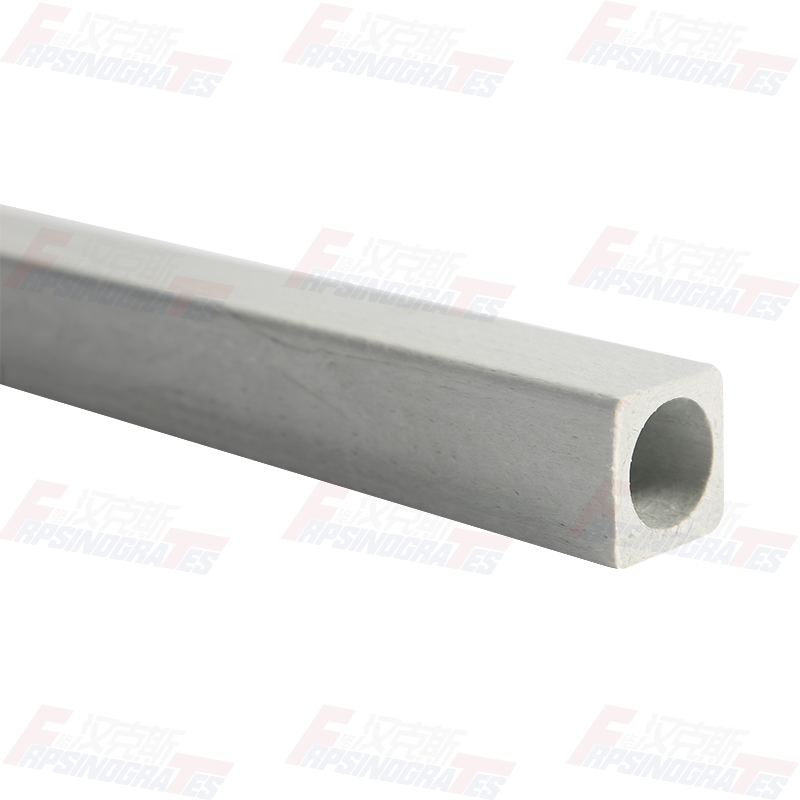

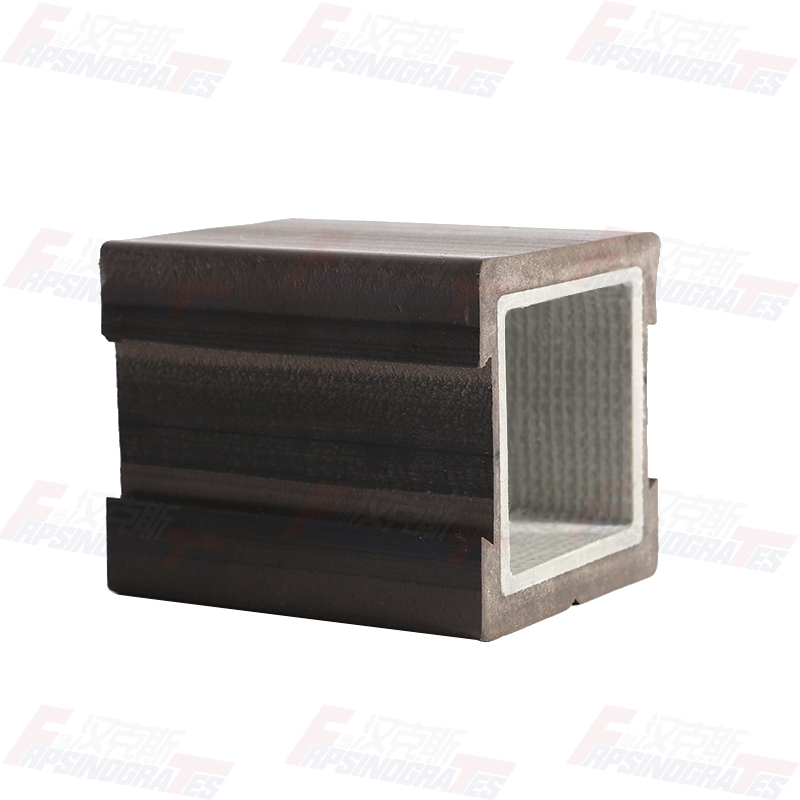

FRP/GRP Pultruded Fiberglass Square paipu

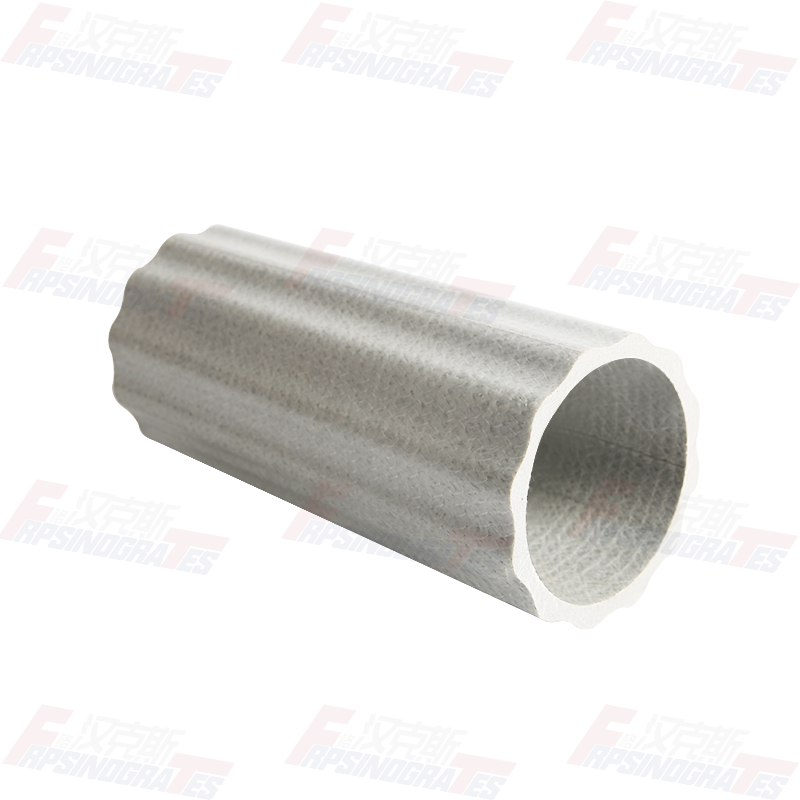

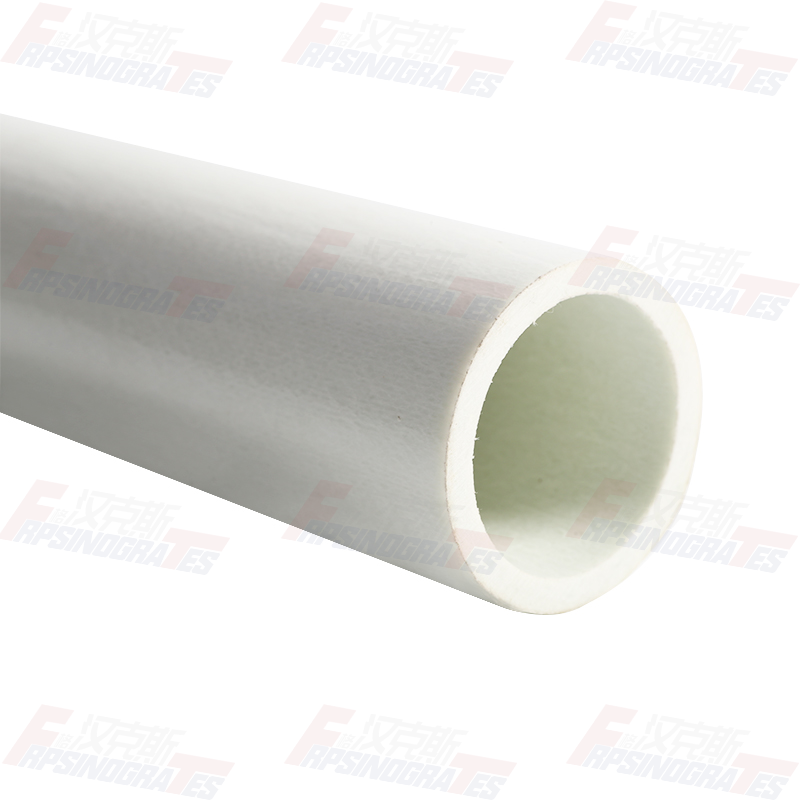

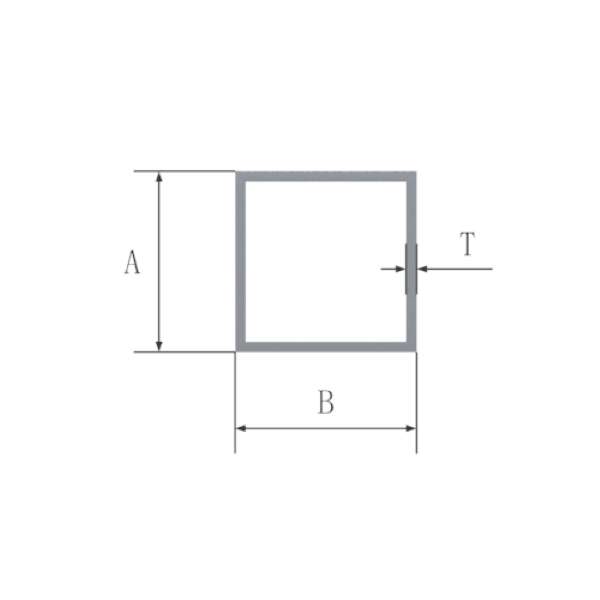

Nā ʻano Molds Tube Round:

| Nā mea kikoʻī | AXBXT(mm) | Kaumaha g/m | SerialNā mea | AXBXT(mm) | Kaumaha g/m |

| 1 | 25X25X3.0 | 32 | 14 | 60X60X7.5 | 540 |

| 2 | 30X30X3.0 | 49 | 15 | 63X63X3.5 | 580 |

| 3 | 38X38X3.0 | 34 | 18 | 63X63X4.0 | 500 |

| 4 | 38X38X3.5 | 61 | 19 | 76X76X5.0 | 1917 |

| 5 | 38X38X4.0 | 77 | 20 | 76X76X6.35 | 1535 |

| 6 | 38X38X7.0 | 92 | 21 | 100X100X3.5 | 1259 |

| 7 | 40X40X5.0 | 87 | 22 | 100X100X4.5 | 1090 |

| 8 | 50X50X4.0 | 99 | 23 | 100X100X6.0 | 1085 |

| 9 | 50X50X5.0 | 114 | 24 | 100X100X8.0 | 815 |

| 10 | 50X50X6.0 | 97 | 25 | 102X102X4.0 | 600 |

| 11 | 50X50X6.3 | 130 | 26 | 102X102X5.5 | 420 |

| 12 | 60X60X5.0 | 110 | 27 | 110X110X8.0 | 610 |

| 13 | 60X60X6.0 | 95 |

Sinogrates@GFRP PULTRUSION:

•Ka ikaika kiʻekiʻe

•Paʻa paʻa

•Māmāmā

•'A'ole i ka po'i

• ʻAʻole-conductive (thermally & uila)

•ʻAʻole-magnetic electromagnetic transparency

•Ka mālama haʻahaʻa

•Pale UV

•Ka ikaika pālua

• Hoʻohaʻahaʻa i ke kumu kūʻai lōʻihi

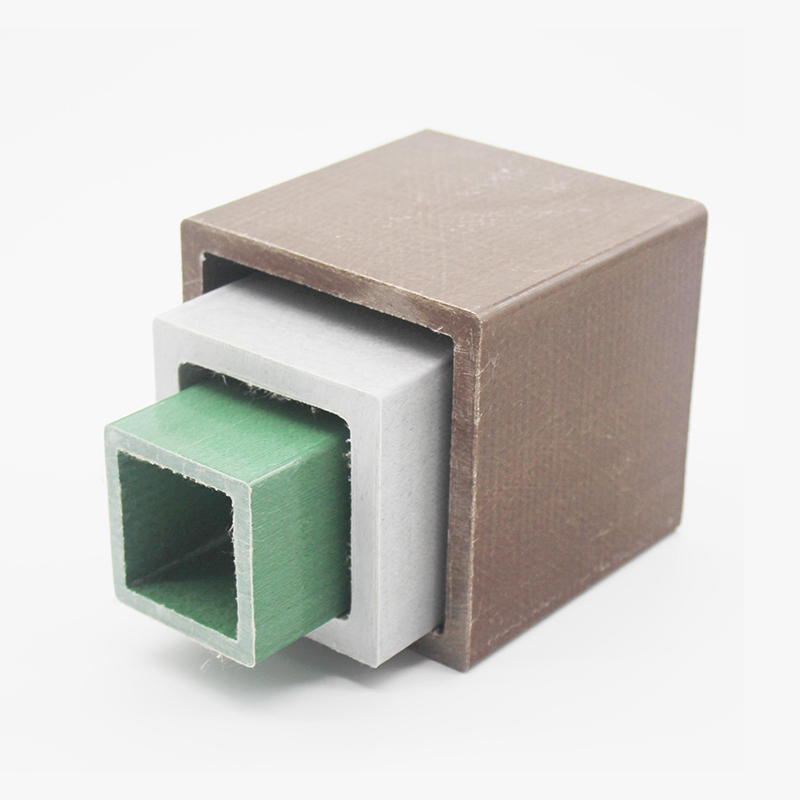

Ke piʻi nui nei ka FRP i mea kaulana no ka hoʻohana ʻana i ke kūkulu ʻana ma muli o kāna mau pono he nui ma mua o nā mea kuʻuna e like me ka lāʻau, ka alumini a me ke kila. ʻAʻole hiki ke popopo, palaho a i ʻole ka hoʻouka ʻana i nā pepeke i hoʻoikaika ʻia i ka fiberglass. Eia kekahi, ʻaʻole lākou e koi i nā mea hoʻomalu a i ʻole nā mea hoʻopau i ka honua a ʻaʻole e komo i ka wai nui. Hoʻopili kēia iā lākou i ka ikaika a me ke ʻano ʻāpana. ʻOi aku ka ikaika o ka fiberglass Pultruded, ʻoi aku ka paʻakikī a ʻoi aku ka māmā ma mua o ka lāʻau kūkulu.

I ka hoʻohālikelike ʻana i nā extrusions aluminika, ʻo ka fiberglass ka uila a me ka thermally non-conductive, ka hopena o ka hopena, ke kūpaʻa nui a me ka EMI/RFI akaka. Ke hoʻohālikelike ʻia me ke kila, ʻoi aku ka pale o ka fiberglass i ka corrosion a ʻaʻole ʻeleʻele ke ʻike ʻia i ka wā a me nā kemika.

Ma ke ʻano holoʻokoʻa, hāʻawi ka fiberglass i nā pono koʻikoʻi ma mua o nā mea kuʻuna e like me ka lāʻau, aluminika a me ke kila, e lilo ia i koho kūpono no nā noi kūkulu hale.

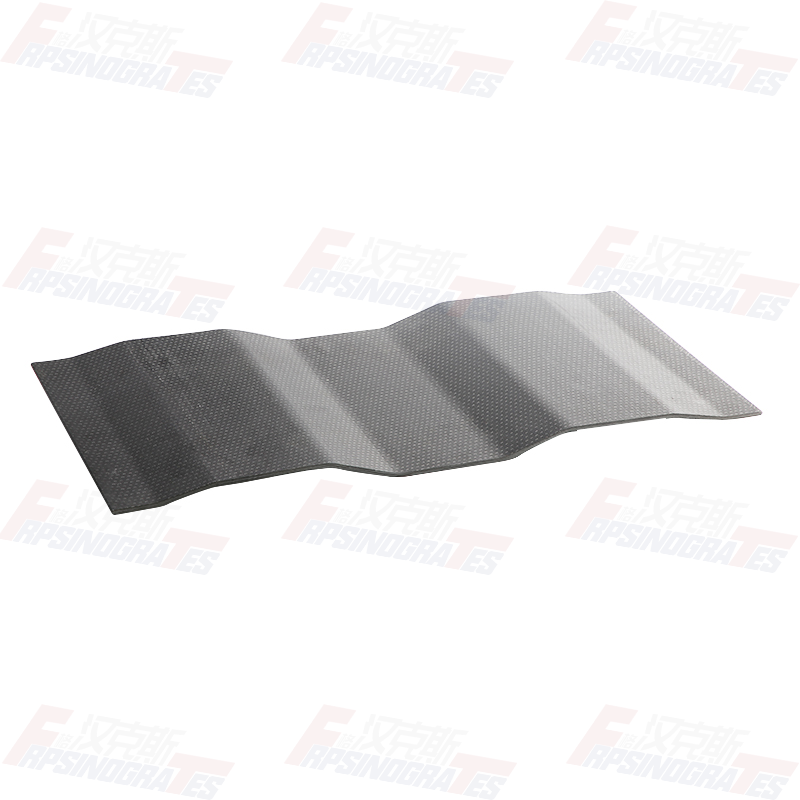

FRP Pultruded profiles Surfaces Manaʻo:

Ma muli o ka nui o nā huahana FRP a me nā kaiapuni like ʻole, ke koho ʻana i nā moena ili ʻokoʻa hiki ke hoʻokō i ka hana kiʻekiʻe e mālama i nā kumukūʻai i kekahi ʻano.

ʻO nā pale i hoʻopaʻa ʻia:

ʻO Continuous Synthetic Surfacing Veils kahi mea maʻamau i hoʻohana ʻia i ka pultruded profiles surface. ʻO ka manaʻo hoʻohuihui mau ʻia he lole silika i hoʻohui ʻia e ka manaʻo mau a me ka manaʻo o ka ʻili. Hiki iā ia ke hōʻoia i ka ikaika i ka hana ʻana i ka ʻili i ʻoi aku ka nani a me ka palupalu. I ka hoʻopā ʻana i ka huahana, ʻaʻole e hou ʻia nā lima o ke kanaka e ka fiber aniani. He kiʻekiʻe ke kumukūʻai o kēia profile. ʻO ka mea maʻamau, hoʻohana ʻia ia ma nā wahi i hoʻopā ʻia ai ka poʻe e nā pā lima lima, ka piʻi ʻana i ke alapiʻi, nā mea paahana, a me nā ʻāina paka. E hoʻohui ʻia kahi hapa nui o nā anti-ultraviolet reagents i ka wā o ke kaʻina hana. Hiki iā ia ke hōʻoia ʻaʻole ia e mae no ka manawa lōʻihi a loaʻa ka hana anti-aging maikaʻi.

moena kaula mau:

ʻO nā moena mānoanoa hoʻomau ka ʻili i hoʻohana mau ʻia i nā kiʻi pultruded nui. Loaʻa i ka moena strand mau ka ikaika a me ka ikaika. Hoʻohana maʻamau ia i nā pou kūkulu nui a me nā kaola. ʻOkaʻiʻo nā ʻili o ka moena strand Continuous. Hoʻohana maʻamau ia i ka ʻāpana kākoʻo ʻoihana e hoʻololi i ke kila a me ka alumini ma ke kahua o ka pale ʻana i ka corrosion. Hoʻohana ʻia ka hoʻohana ʻana i nā profiles nui i nā hale i hoʻopā pinepine ʻole ʻia e nā kānaka. He maikaʻi nā kumukūʻai o kēia ʻano profile. He kūpono ia no nā noi nui i ka ʻenekinia. Hiki iā ia ke ho'ēmi pono i ke kumukūʻai o ka hoʻohana a hōʻoia i ka hana o ka huahana.

Moena kaula hui mau:

ʻO ka moena strand continuous compound he lole fiberglass e nalu ana i haku ʻia me nā pale i luna a me nā moena strand mau, nona ka ikaika maikaʻi a me ke ʻano maikaʻi. Hiki iā ia ke kōkua maikaʻi e hōʻemi i nā kumukūʻai. ʻO ia nā koho ʻoi aku ka maikaʻi inā koi kiʻekiʻe a me nā hiʻohiʻona. Hiki ke hoʻohana ʻia i ka ʻenehana pale lima. Hiki iā ia ke hoʻokō pono i ka pono ikaika a loaʻa ka pale lima lima o nā kānaka.

ʻO nā pale i hoʻopaʻa ʻia ma luna o ka lāʻau.

Wood Grain Continuous Synthetic Surfacing Veils kekahi ʻano o ka lole fiberglass e nalu

Loaʻa iā ia ka hana ikaika maikaʻi e like me nā huahana lāʻau. He mea pani ia no nā huahana lāʻau e like me nā ʻāina, nā pā, nā pā hale, nā pā hale, a me nā mea ʻē aʻe. ʻOi aku ka lōʻihi o ke ola ma kahakai a i ʻole ka lā lōʻihi.

ʻO nā pale i hoʻopaʻa ʻia

moena lauwili mau

moena kaula hui mau

ʻO nā pale i hoʻopaʻa ʻia i ka ʻili lāʻau

Nā huahana hoʻokolohua hoʻokolohua:

ʻO nā mea hoʻokolohua koʻikoʻi no ka FRP pultruded profiles a me ka FRP molded gratings, e like me nā hoʻāʻo flexural, nā hoʻāʻo tensile, nā hoʻāʻo ʻana, a me nā hoʻāʻo luku. E like me nā koi o nā mea kūʻai aku, e hana mākou i nā hōʻike hōʻike a me nā mana i nā huahana FRP, mālama i nā moʻolelo e hōʻoia i ka paʻa o ka maikaʻi no ka wā lōʻihi. Hiki iā mākou ke hōʻoia i ka maikaʻi e hoʻokō pono i nā koi o nā mea kūʻai aku e pale i nā pilikia ma hope o ke kūʻai aku.

Nā koho ʻōnaehana FRP Resins:

Phenolic resin (ʻAno P): ʻO ke koho maikaʻi loa no nā noi e koi ana i ka nui o ka pale ahi a me ka uahi haʻahaʻa e like me nā mea hoʻoheheʻe aila, nā hale hana kila, a me nā deck pier.

Vinyl Ester (ʻAno V): pale i nā kaiaola kemika koʻikoʻi i hoʻohana ʻia no ke kemika, ka mālama ʻana i ka ʻōpala, a me nā mea kanu hana.

Isophthalic resin (ʻano I): ʻO kahi koho maikaʻi no nā noi kahi mea maʻamau ka paʻi ʻana a me ke kahe ʻana.

ʻAi ʻAi Isophthalic resin (ʻAno F): He kūpono no nā hale ʻoihana meaʻai a me nā mea inu i ʻike ʻia i nā kaiapuni maʻemaʻe.

ʻO ka resin orthothphalic kumu nui (ʻano O): nā mea ʻē aʻe i ka vinyl ester a me nā huahana isophthalic resins.

Epoxy Resin (ʻAno E):hāʻawi i nā waiwai mechanical kiʻekiʻe a me ke kūpaʻa luhi, e lawe i nā pono o nā resins ʻē aʻe. Ua like nā kumukūʻai mold me PE a me VE, akā ʻoi aku ka kiʻekiʻe o nā kumukūʻai.

ʻO ka polyester a me ka vinyl ester resins ka mea maʻamau i hoʻohana ʻia matrix resins e hana i nā ʻāpana composite.

ʻO nā resine polyester, ʻike ʻia hoʻi ʻo Unsaturated Polyester Resins (UPR), i hui pū ʻia me nā fiberglass reinforcements ʻo ia nā mea kūkulu hale o ka ʻoihana composites no nā makahiki he mau makahiki. Hāʻawi kēia mau hana i ke kumu kūʻai haʻahaʻa, maʻalahi o ka lawelawe ʻana, hoʻōla wikiwiki, a me ka ikaika kiʻekiʻe e hana i nā ʻāpana like ʻole o nā ʻāpana composite i nā noi he nui. He kūpono lākou no ka hoʻoheheʻe ʻia ʻana a me nā kaʻina hana hoʻoheheʻe ʻia e like me ka hana ʻana o ka infusion vacuum, ka hoʻololi ʻana i ka resin, ka filament winding, ka compression molding a me ka pultrusion. ʻO ka polyester resin ka mea nui resin matrix i hoʻohana ʻia i ka hoʻoheheʻe ʻana, nā pūhui hoʻoheheʻe nui (BMC) a me nā pūhui hoʻoheheʻe pepa (SMC), a i ke kaʻina hana pultrusion.

Loaʻa nā ʻano like ʻole o ka polyester resin formulations i loaʻa no nā noi kikoʻī. Aia kēia mau mea:

- ʻO Ortohphthalic (Ortho) ma muli o ka resin kumu nui

- Isophthalic (Iso) hoʻokumu i ka resin me ka hoʻohaunaele wela kiʻekiʻe a hoʻomaikaʻi i ka pale ʻana i ka corrosion

- ʻO Dicyclopentadiene (DCPD) i hoʻokumu ʻia i ka resin no ka haʻahaʻa haʻahaʻa a me ka hoʻomaikaʻi ʻana i nā mea hoʻonaninani

- ʻO nā resins kūikawā no ka hana ahi, lawelawe meaʻai, a i ʻole ke kūpaʻa corrosion

ʻO ka Vinyl ester resins (VE) he molekele iwi kuamoʻo polyester me kahi mea epoxy. Hāʻawi nā kumu Vinyl ester i hoʻonui i ka pale ʻana i ka corrosion a loaʻa kahi ākea o ka ikaika i loaʻa, ka wela wela, a me nā hiʻohiʻona shrinkage.

Nā alakaʻi koho resins:

| ʻAno Resin | Koho Resin | Waiwai | Kūʻē Kemika | Paʻa ahi (ASTM E84) | Nā huahana | Nā waihoʻoluʻu i koho ʻia | Max ℃ Temp |

| ʻAno P | Phenolic | ʻO ka uahi haʻahaʻa a me ke kūpaʻa ahi kiʻekiʻe | Maikaʻi loa | Papa 1, 5 a emi mai | Molded and Pultruded | Nā waihoʻoluʻu i koho ʻia | 150 ℃ |

| ʻAno V | Vinyl Ester | ʻOi aku ka pale ʻana i ka ʻino a me ke ahi | maikaʻi loa | Papa 1, 25 a emi mai | Molded and Pultruded | Nā waihoʻoluʻu i koho ʻia | 95 ℃ |

| ʻAno I | Isophthalic polyester | ʻO ke kūʻē ʻana i ke ahi a me ke ahi | Maikaʻi loa | Papa 1, 25 a emi mai | Molded and Pultruded | Nā waihoʻoluʻu i koho ʻia | 85 ℃ |

| ʻAno O | ʻO Ortho | ʻO ke kūpaʻa ʻino a me ka pale ahi | Maʻamau | Papa 1, 25 a emi mai | Molded and Pultruded | Nā waihoʻoluʻu i koho ʻia | 85 ℃ |

| ʻAno F | Isophthalic polyester | ʻAi ʻAi ʻAi ʻAi a me ke ahi | Maikaʻi loa | Papa 2, 75 a emi mai | Hana ʻia | Palaunu | 85 ℃ |

| ʻAno E | Epoxy | ʻOi aku ka pale ʻana i ka corrosion a me ka pale ahi | maikaʻi loa | Papa 1, 25 a emi mai | Pultruded | Nā waihoʻoluʻu i koho ʻia | 180 ℃ |

Wahi a nā kaiapuni like ʻole a me nā noi, koho ʻia nā resins ʻokoʻa, hiki iā mākou ke hāʻawi i kekahi mau ʻōlelo aʻoaʻo!

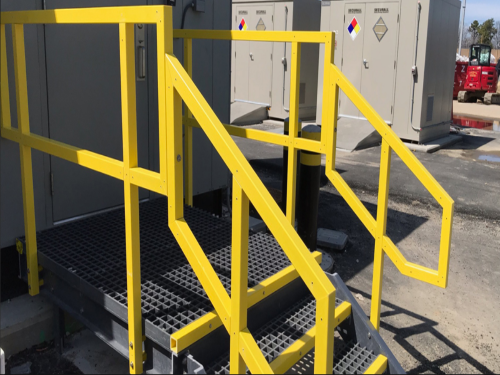

Wahi a nā noi, hiki ke hoʻohana ʻia nā handrails i nā ʻano like ʻole:

♦Kukumu lima ♦Kukukau lima ♦Kukukau lima ♦Kukui Balkona

♦ Nā Kūʻai Kūʻai ♦ Nā Kūleʻa Kūwaho ♦ Nā Pūnaehana Kūʻai Kūwaho ♦ Nā Handrails o waho

♦ Nā Alapiʻi Kūwaho ♦ Nā Alapiʻi a me nā ʻauamo ♦ Nā Kūʻai Kūʻai Kūʻai ♦ Ke Alanui ʻOihana

♦ Nā Pākuʻi Kūwaho ♦ Nā Pākuʻi Kūwaho ♦ Nā Kūʻai Kūʻai Kūʻai ♦Bannister

♦ kaʻa ♦ nā ʻōnaehana hoʻopaʻa lima ♦ nā lima lima ♦

♦Deck Railing ♦Deck Railings ♦Deck Stair Handrail ♦Stair Railing Systems

♦Kukui kia’i ♦Paku lima palekana ♦Pa Ka’a Ka’a ♦ Na Ala’ipii.

♦Kukuʻu alapiʻi ♦Kukuʻu alapiʻi ♦Kukuʻu alapiʻi ♦Pa a me nā ʻīpuka

ʻO kekahi mau mea hoʻohui SMC lima lima: