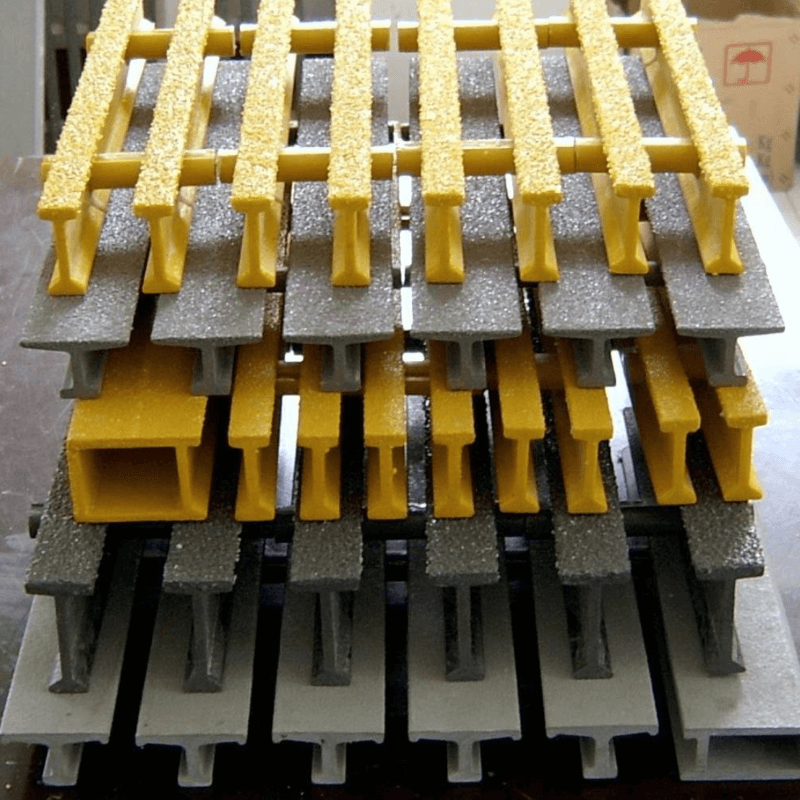

ʻO FRP Pultruded Grating Fire Retardant/Chemical Resistant

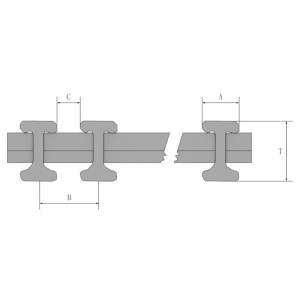

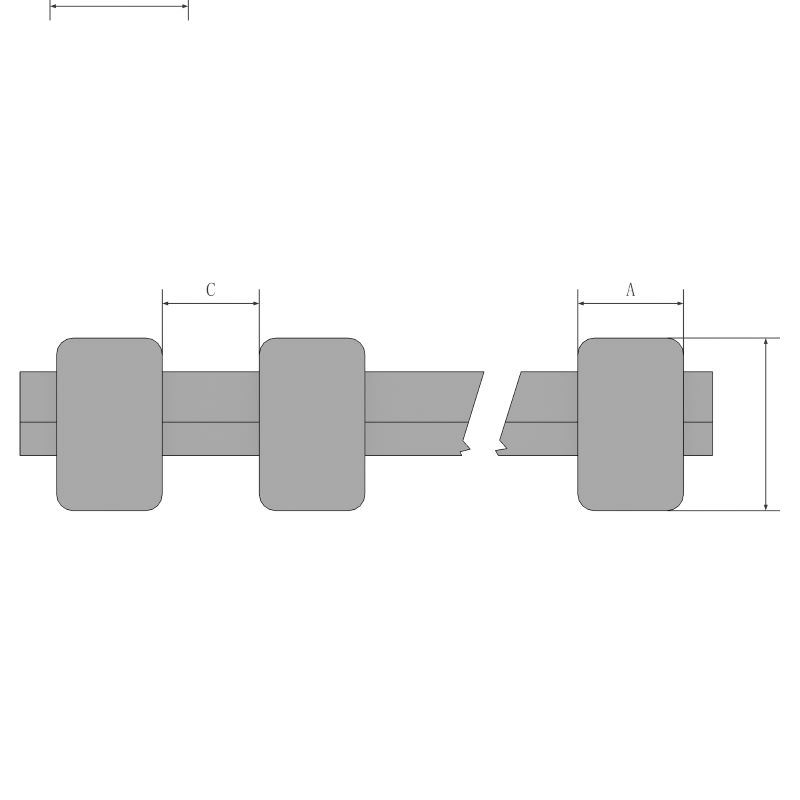

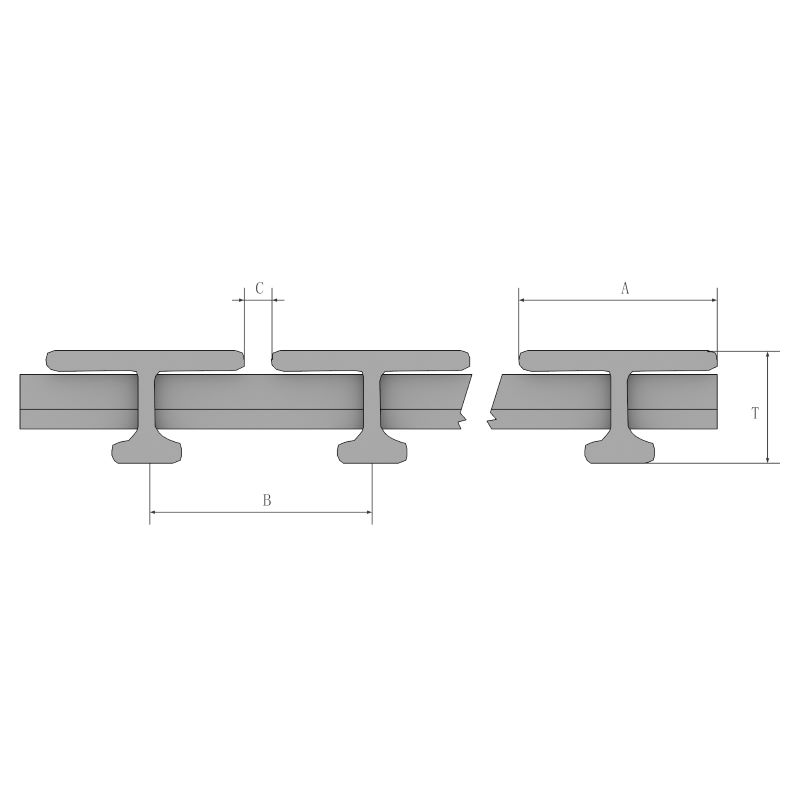

Nā ʻāpana o ka FRP Pultruded grating hōʻikeʻike:

| I-5010 | 50 | 15 | 25 | 10 | 40 | 28.5 |

| I-5015 | 50 | 15 | 30 | 15 | 50 | 24.2 |

| I-5023 | 50 | 15 | 38 | 23 | 60 | 20.1 |

| T-2510 | 25 | 38 | 43.4 | 5.4 | 12 | 15.6 |

| T-2515 | 25 | 38 | 50.8 | 9.5 | 18 | 13.9 |

| T-2520 | 25 | 38 | 50.8 | 12.7 | 25 | 13.6 |

| T-2530 | 25 | 38 | 61 | 19.7 | 33 | 11.2 |

| T-3810 | 38 | 38 | 43.3 | 5.2 | 12 | 19.6 |

| T-3815 | 38 | 38 | 50.8 | 12.7 | 25 | 16.7 |

| T-3820 | 38 | 38 | 61 | 23 | 38 | 14.3 |

| T-5010 | 50 | 25.4 | 38.1 | 12.7 | 33 | 21.8 |

| T-5015 | 50 | 25.4 | 50.8 | 25.4 | 50 | 17.4 |

| H-5010 | 50 | 15 | 10 | 10 | 40 | 63 |

| H-5015 | 50 | 15 | 15 | 15 | 50 | 52.3 |

| H-5020 | 50 | 15 | 23 | 23 | 60 | 43.6 |

| ʻAno Pultruded Grating | Kiʻekiʻe (mm) | laula ʻaoʻao o luna (mm) | Wahi ma waena (mm) | Laulā hoʻomaʻemaʻe (mm) | Wahi hāmama(%) | Kaumaha Kg/㎡ |

| I-2510 | 25 | 15 | 25 | 10 | 40 | 17.8 |

| I-2515 | 25 | 15 | 30 | 15 | 50 | 15.2 |

| I-2523 | 25 | 15 | 38 | 23 | 60 | 12.2 |

| I-3810 | 38 | 15 | 25 | 10 | 40 | 22 |

| I-3815 | 38 | 15 | 30 | 15 | 50 | 19.1 |

| I-3823 | 38 | 15 | 38 | 23 | 60 | 16.2 |

| I-3010 | 30 | 15 | 25 | 10 | 40 | 19.1 |

| I-3015 | 30 | 15 | 30 | 15 | 50 | 16.1 |

| I-3023 | 30 | 15 | 38 | 23 | 60 | 13.1 |

Nā koho ʻōnaehana FRP Resins:

Nā alakaʻi koho resins:

| ʻAno Resin | Koho Resin | Waiwai | Kūʻē Kemika | Paʻa ahi (ASTM E84) | Nā huahana | Nā waihoʻoluʻu i koho ʻia | Max ℃ Temp |

| ʻAno P | Phenolic | ʻO ka uahi haʻahaʻa a me ke kūpaʻa ahi kiʻekiʻe | Maikaʻi loa | Papa 1, 5 a emi mai | Molded and Pultruded | Nā waihoʻoluʻu i koho ʻia | 150 ℃ |

| ʻAno V | Vinyl Ester | ʻOi aku ka pale ʻana i ka ʻino a me ke ahi | Maikaʻi | Papa 1, 25 a emi mai | Molded and Pultruded | Nā waihoʻoluʻu i koho ʻia | 95 ℃ |

| ʻAno I | Isophthalic polyester | ʻO ke kūʻē ʻana i ke ahi a me ke ahi | Maikaʻi loa | Papa 1, 25 a emi mai | Molded and Pultruded | Nā waihoʻoluʻu i koho ʻia | 85 ℃ |

| ʻAno O | ʻO Ortho | ʻO ke kūpaʻa ʻino a me ka pale ahi | Maʻamau | Papa 1, 25 a emi mai | Molded and Pultruded | Nā waihoʻoluʻu i koho ʻia | 85 ℃ |

| ʻAno F | Isophthalic polyester | ʻAi ʻAi ʻAi ʻAi a me ke ahi | Maikaʻi loa | Papa 2, 75 a emi mai | Hana ʻia | Palaunu | 85 ℃ |

| ʻAno E | Epoxy | ʻOi aku ka pale ʻana i ka corrosion a me ka pale ahi | Maikaʻi | Papa 1, 25 a emi mai | Pultruded | Nā waihoʻoluʻu i koho ʻia | 180 ℃ |

Nā waihoʻoluʻu i koho ʻiaWahi a nā kaiapuni like ʻole a me nā noi, koho ʻia nā resins ʻokoʻa, hiki iā mākou ke hāʻawi i kekahi mau ʻōlelo aʻoaʻo!

Phenolic resin (ʻAno P): ʻO ke koho maikaʻi loa no nā noi e koi ana i ka nui o ke ahi ahi a me ka uahi haʻahaʻa e like me nā mea hoʻoheheʻe aila, nā hale hana kila, a me nā deck pier.

Vinyl Ester (ʻAno V): pale i nā kaiaola kemika ikaika i hoʻohana ʻia no ka lāʻau kemika, ka hoʻomaʻemaʻe ʻōpala, a me nā mea kanu hana.

Isophthalic resin (ʻano I): He koho maikaʻi no nā noi kahi mea maʻamau ka paʻi ʻana a me ke kahe ʻana.

ʻAi ʻAi Isophthalic resin (ʻAno F): He kūpono no nā hale ʻoihana meaʻai a me nā mea inu e ʻike ʻia i nā wahi maʻemaʻe maʻemaʻe.

ʻO ka resin orthothphalic kumu nui (ʻano O): nā mea ʻokoʻa hoʻokele waiwai i nā huahana vinyl ester a me isophthalic resins.

Epoxy Resin (ʻAno E):hāʻawi i nā waiwai mechanical kiʻekiʻe a me ke kūpaʻa luhi, e lawe i nā pono o nā resins ʻē aʻe. Ua like nā kumukūʻai mold me PE a me VE, akā ʻoi aku ka kiʻekiʻe o nā kumukūʻai.

Nā huahana hoʻokolohua hoʻokolohua:

ʻO nā mea hoʻokolohua koʻikoʻi no ka FRP pultruded profiles a me ka FRP molded gratings, e like me nā hoʻāʻo flexural, nā hoʻāʻo tensile, nā hoʻāʻo ʻana, a me nā hoʻāʻo luku. E like me nā koi o nā mea kūʻai aku, e hana mākou i nā hōʻike hōʻike a me nā mana i nā huahana FRP, mālama i nā moʻolelo e hōʻoia i ka paʻa o ka maikaʻi no ka wā lōʻihi. Hiki iā mākou ke hōʻoia i ka maikaʻi e hoʻokō pono i nā koi o nā mea kūʻai aku e pale i nā pilikia ma hope o ke kūʻai aku.

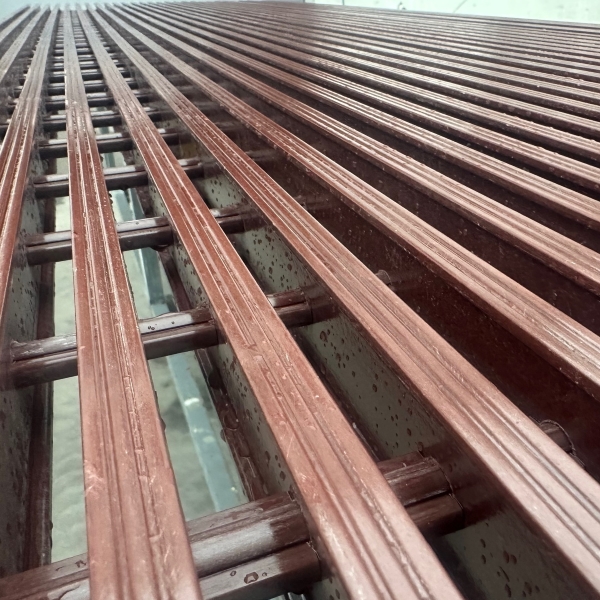

SINOGRATES@FRP Pultrusion Grating

ʻO ke kaʻina hana Pultrusion he kaʻina hana no ka hana ʻana i nā lōʻihi mau o ka hoʻoikaika ʻana i ka polymer structural profiles me nā ʻāpana keʻa mau. ʻO nā mea waiwai kahi hui resin wai ( resins, fillers a me nā mea hoʻohui kūikawā) a me ka textile hiki ke hoʻoikaika i ka fiberglass rovings. ʻO ke kaʻina hana no ka huki ʻana i kēia mau mea maka (ma mua o ka hoʻokuke ʻana, e like me ke ʻano o ka extrusion) ma o ke kila wela me ka hoʻohana ʻana i kahi mea huki hoʻomau.

Aia nā mea i hoʻoikaika ʻia i nā ʻano hoʻomau e like me nā ʻōwili o nā moena fiberglass a me nā doffs o ka fiberglass rovings. I ka piha ʻana o nā mea hoʻoikaika me ka hui resins ("wet-out") i loko o ka ʻauʻau resin a huki ʻia i loko o ka make, ka gelation, a i ʻole ka paʻakikī, hoʻomaka ʻia ka resin e ka wela mai ka make a ua hoʻokumu ʻia kahi ʻano paʻa, hoʻōla ʻia e like me ke ʻano o ka make.

Hele mai ka FRP Pultrusion grating i ʻekolu mau ʻāpana: ʻO nā kaola I-Shape, nā kaola T-Shape, a me nā kaola High-Load no nā noi kaumaha.