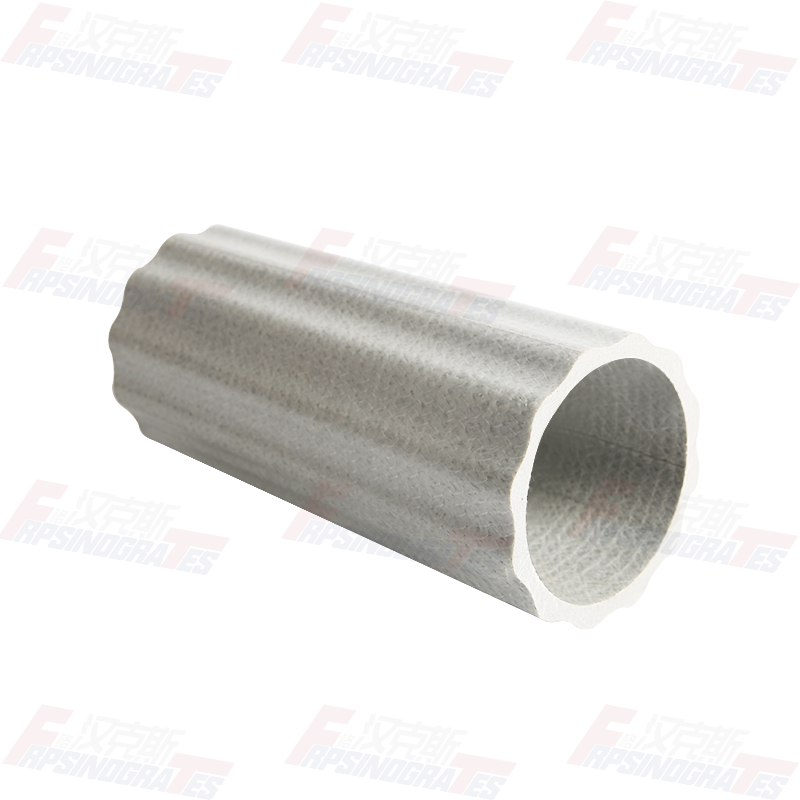

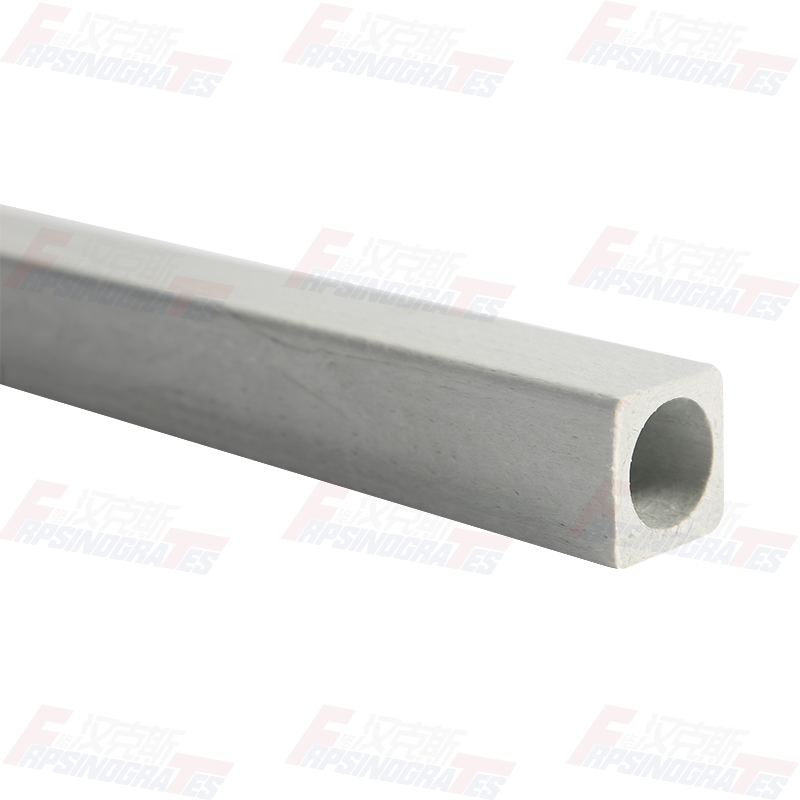

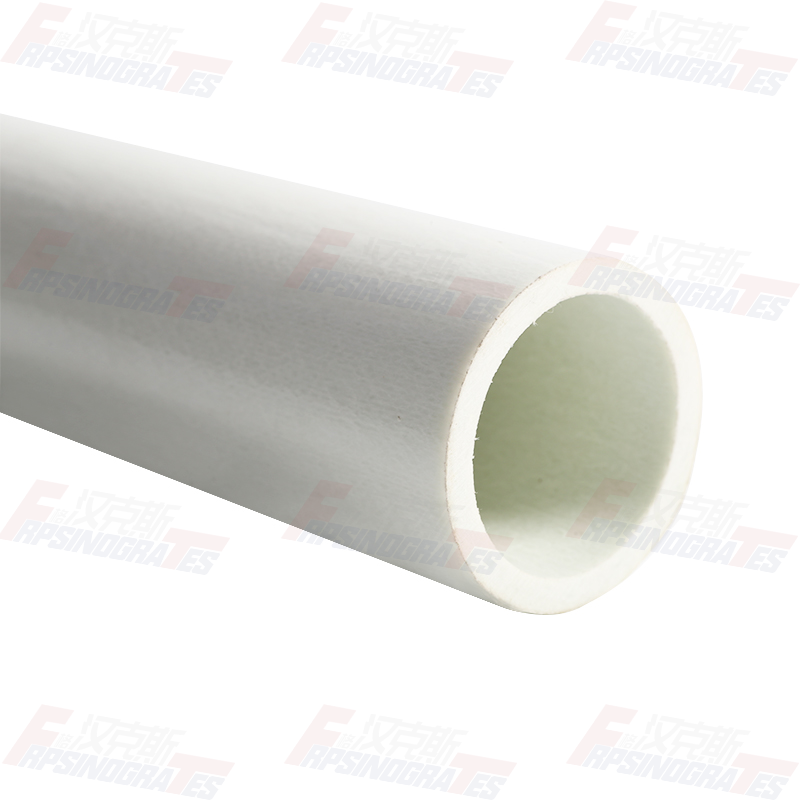

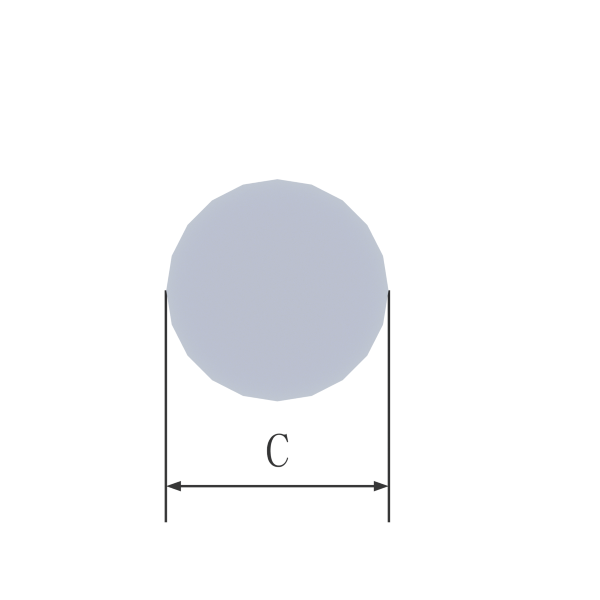

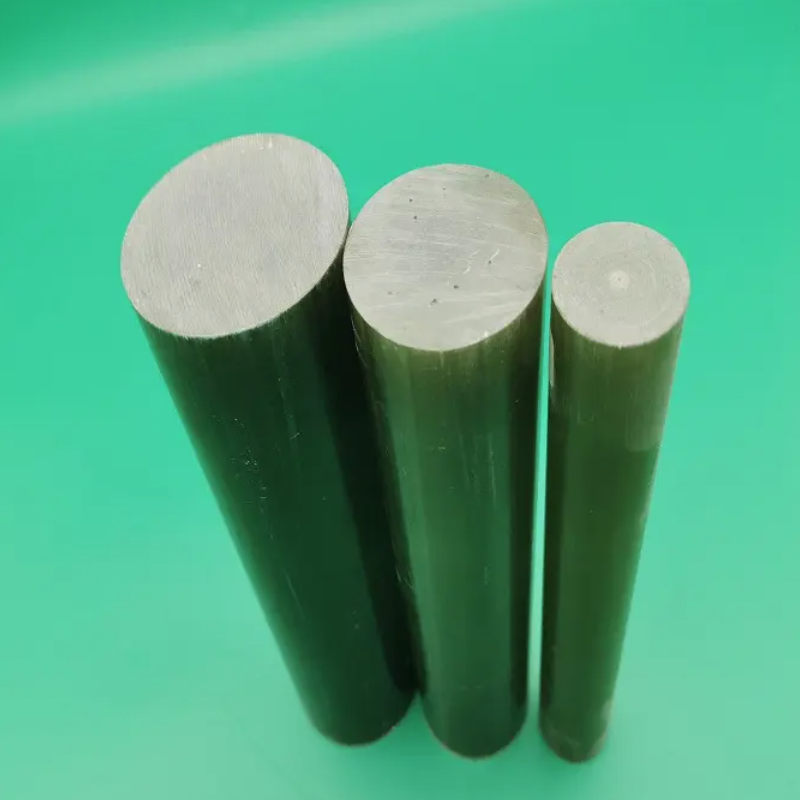

FRP / GRP Fiberglass pultruded Round Khoom Qws

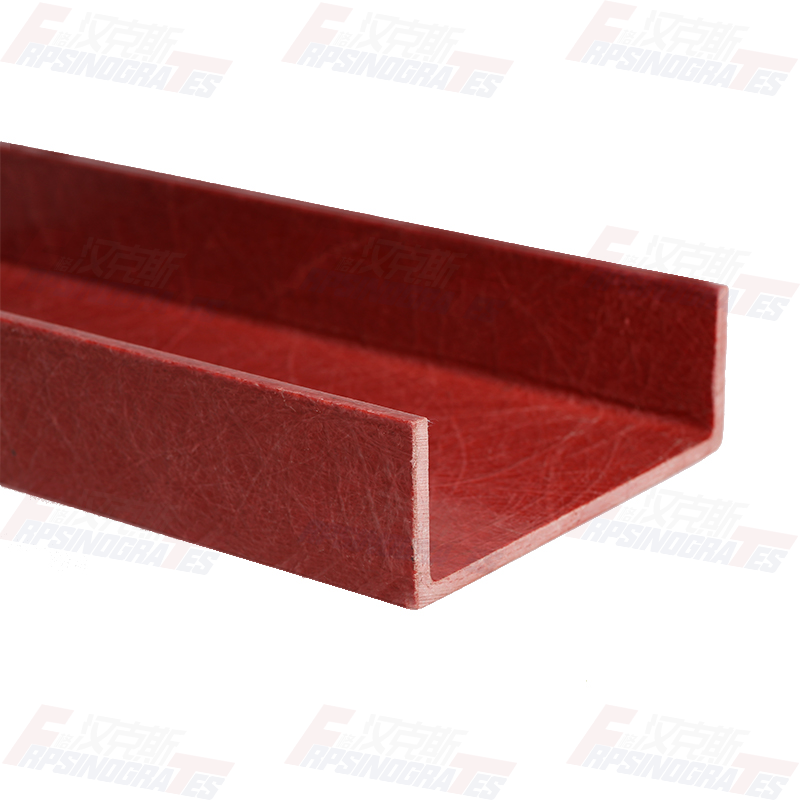

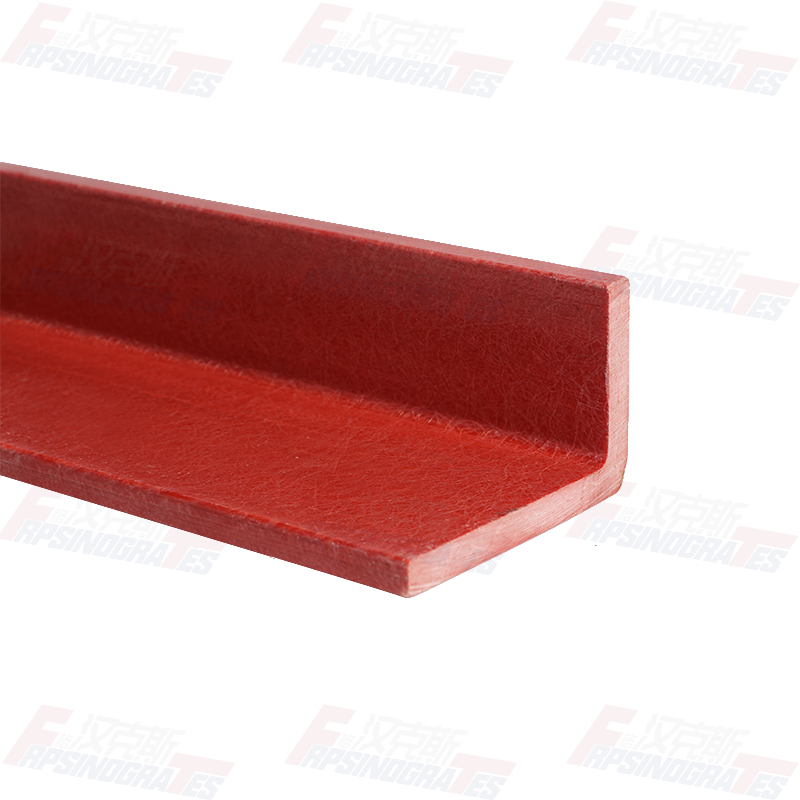

Fiberglass Angle Moulds Hom:

| SerialCov khoom | C = Ø (mm) | Qhov hnyav g / m | Yam khoom Serial | C = Ø (mm) | Qhov hnyav g / m | Yam khoom Serial | C = Ø (mm) | Qhov hnyav g / m |

| 1 | Ø 3.0 | 14g ua | 12 | Ø 10 | 15 5g | 23 | Ø 20 | 610g ua |

| 2 | Ø 4.0 | 26g ua | 13 | Ø 11 | 176g ua | 24 | Ø 21 | 640g ua |

| 3 | Ø 4.52 | 32g ua | 14 | Ø 12 | 226g ua | 25 | Ø 22 | 731g ua |

| 4 | Ø 5.0 | 40g ua | 15 | Ø 12.7 | 234g ua | 26 | Ø 23.5 | 802g ua |

| 5 | Ø 6.0 | 56g ua | 16 | Ø 14 | 292g ua | 27 | Ø 25 | 950g ua |

| 6 | Ø6.35 Nws | 57g ua | 17 | Ø 15 | 340g ua | 28 | Ø 30 | 1 410g |

| 7 | Ø 7.0 | 71g ua | 18 | Ø 16 | 380g ua | 29 | Ø 32 | 1452g ua |

| 8 | Ø 8.0 Nws | 93g ua | 19 | Ø 16.3 | 396g ua | |||

| 9 | Ø 8.5 | 105g ua | 20 | Ø 17 | 454g ua | |||

| 10 | Ø 9.0 Nws | 12 7g | 21 | Ø 18 | 492g ua | |||

| 11 | Ø 9.5 | 134g ua | 22 | Ø 19 | 510g ua |

Sinogrates@GFRP PULTRUSION:

• Tsawg ceev

• Siab elasticity

•Sterilizer

• Corrosion

• Yooj yim

• Zoo saib

• Tus nqi tu qis

• rwb thaiv tsev

• Tus nqi qis

• tiv thaiv UV

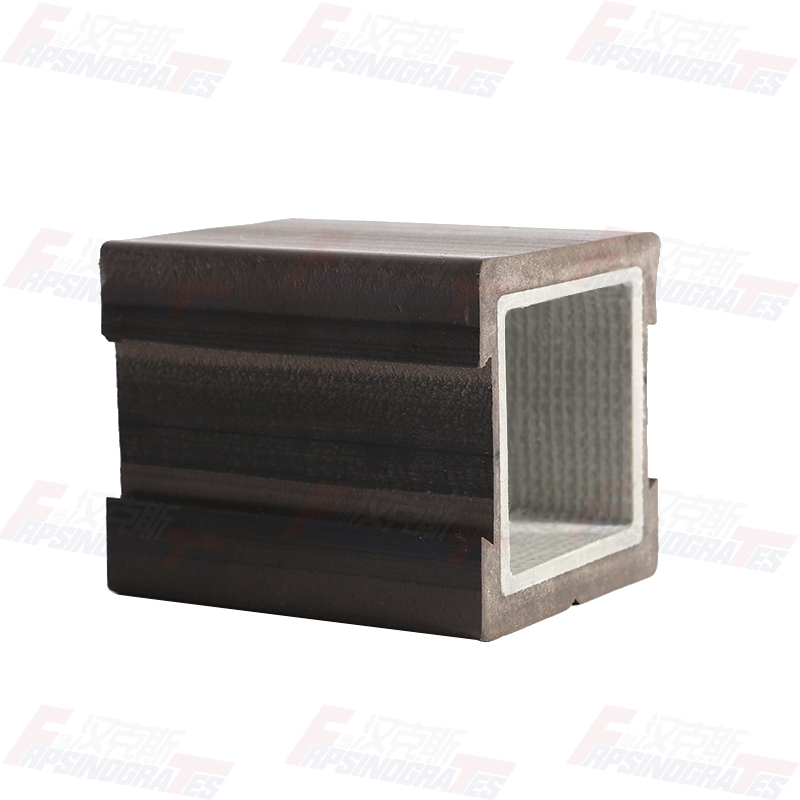

Sinogrates yog lub chaw tsim khoom ntawm fiberglass pultrusion rods rau ntau yam kev lag luam thiab kev siv. Peb cov khoom tsim los ua kom tau raws li cov qauv siab tshaj plaws ntawm kev ua tau zoo thiab kev ua tau zoo, kom ntseeg tau tias koj tau txais txiaj ntsig zoo tshaj plaws los ntawm koj cov haujlwm. Peb cov pas nrig pultruded yog siv rau hauv txhua yam los ntawm cov khoom ua si rau cov roj thiab roj, yog li txawm tias koj xav tau dab tsi, Sinogrates muaj kev daws teeb meem.

Peb cov pas nrig pultruded tau siv ntau yam kev siv, los ntawm hom qhuav transformer spacers thiab daus ncej mus rau chij sticks thiab vaj cim. Peb kuj tau tsim cov axles, gripper rods, cuab yeej tuav, cov khoom siv hluav taws xob, kev lag luam kos npe ncej, golf chij, motor wedges, awning stiffeners, oil field sucker rods, sports equipment, tent ncej, laj kab post stiffeners, thiab standoff insulators.

Raws li Sinogrates, peb nkag siab qhov tseem ceeb ntawm kev xa cov khoom lag luam zoo uas yuav sawv qhov kev sim ntawm lub sijhawm. Tias yog vim li cas peb tau saib xyuas ntxiv kom ntseeg tau tias peb cov pas nrig pultruded tau ua rau cov qauv siab tshaj plaws, yog li koj tuaj yeem muaj kev ntseeg siab rau koj qhov project.

Txawm hais tias koj xav tau dab tsi, Sinogrates muaj qhov zoo tshaj plaws pultruded rods rau koj. Nrog peb cov khoom zoo thiab pab neeg ua haujlwm, koj tuaj yeem so kom paub tseeb tias koj qhov project yuav ua tiav nrog cov txiaj ntsig zoo tshaj plaws. Tiv tauj peb hnub no kom paub ntau ntxiv txog peb cov pas nrig pultruded thiab peb tuaj yeem pab koj li cas rau koj qhov project tom ntej.

Product Capacities Test Laboratory:

Cov cuab yeej siv tshuaj ntsuam xyuas zoo rau FRP pultruded profiles thiab Fiberglass molded gratings, xws li kev sim flexural, tensile tests, compression tests, thiab destructive tests. Raws li cov neeg siv khoom xav tau, peb yuav ua qhov kev ua tau zoo & kev ntsuas lub peev xwm ntawm FRP cov khoom, khaws cov ntaub ntawv kom ruaj ntseg zoo rau lub sijhawm ntev. Peb tuaj yeem xyuas kom meej tias qhov zoo tuaj yeem ua rau cov neeg siv khoom xav tau ruaj khov kom tsis txhob muaj teeb meem tom qab muag khoom. 修正

FRP Resins Systems Xaiv:

Phenolic resin (Hom P): Qhov kev xaiv zoo tshaj plaws rau cov ntawv thov uas xav tau cov hluav taws kub retardant thiab cov pa luam yeeb tsawg xws li cov roj refineries, steel factories, thiab pier decks.

Vinyl Ester (Hom V): tiv taus cov tshuaj lom neeg nruj heev uas siv rau kev siv tshuaj lom neeg, pov tseg kev kho mob, thiab cov nroj tsuag tsim.

Isophthalic resin (Hom I): Ib qho kev xaiv zoo rau cov ntawv thov uas muaj tshuaj txau thiab nchuav yog ib qho tshwm sim.

Khoom noj khoom haus qib Isophthalic resin (Hom F): Qhov zoo tshaj plaws rau cov khoom noj khoom haus thiab dej haus kev lag luam uas raug rau ib puag ncig huv si.

General Purpose Orthothphalic resin (Hom O): Kev lag luam hloov pauv rau cov khoom siv yas ester thiab isophthalic resins.

Epoxy Resin (Hom E):muab cov cuab yeej zoo heev thiab qaug zog ua haujlwm, noj qhov zoo ntawm lwm cov resins. Pwm cov nqi zoo ib yam li PE thiab VE, tab sis cov nqi khoom kim dua.

Resins Option Guide Guide:

| Resin Hom | Resin Option | Cov khoom | Tshuaj tiv thaiv | Hluav taws kub Retardant (ASTM E84) | Cov khoom | Xim Xim | Max kub ℃ |

| Hom P | Phenolic | Tsawg pa luam yeeb thiab Superior Fire Resistance | Zoo heev | Chav Kawm 1, 5 lossis tsawg dua | Moulded thiab Pultruded | Xim Xim | 150 ℃ |

| Hom V | Vinyl Ester | Superior Corrosion Resistance thiab hluav taws kub retardant | Zoo heev | Chav Kawm 1, 25 lossis tsawg dua | Moulded thiab Pultruded | Xim Xim | 95 ℃ |

| Hom I | Isophthalic polyester | Muaj Qib Corrosion Resistance thiab hluav taws kub retardant | Zoo heev | Chav Kawm 1, 25 lossis tsawg dua | Moulded thiab Pultruded | Xim Xim | 85 ℃ |

| Hom O | Ortho | Nruab nrab Corrosion Resistance thiab hluav taws kub retardant | Ib txwm | Chav Kawm 1, 25 lossis tsawg dua | Moulded thiab Pultruded | Xim Xim | 85 ℃ |

| Hom F | Isophthalic polyester | Food Grade Corrosion Resistance thiab Fire Retardant | Zoo heev | Chav Kawm 2, 75 lossis tsawg dua | Moulded | Xim av | 85 ℃ |

| Hom E | Epoxy | Zoo heev corrosion kuj thiab hluav taws kub retardant | Zoo heev | Chav Kawm 1, 25 lossis tsawg dua | Pultruded | Xim Xim | 180 ℃ |

Raws li qhov chaw sib txawv thiab kev siv, xaiv cov resins sib txawv, peb kuj tuaj yeem muab qee cov lus qhia!

Raws li cov ntawv thov, nws tuaj yeem hloov mus rau qhov kev thov ib puag ncig:

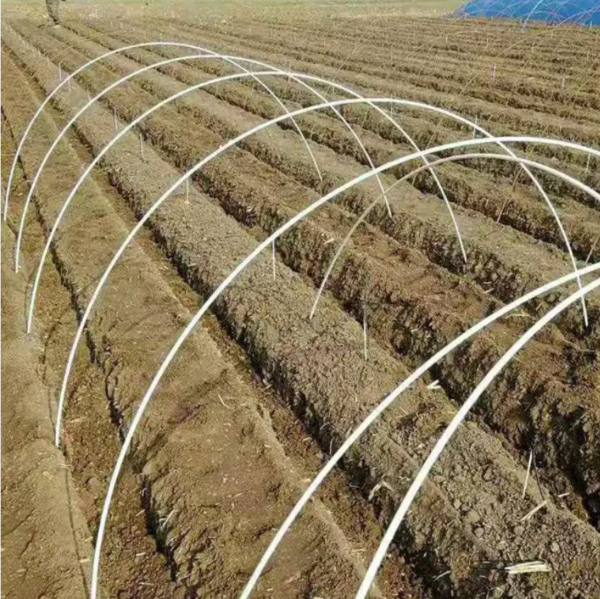

♦ Sab nraum zoov ncej

♦ Sab nraum lub tsev pheeb suab stent

♦ Kite khib

♦ Lub kaus

♦ Flag pas nrig

♦ ncej

♦ Yog

♦ Qauv dav hlau khib

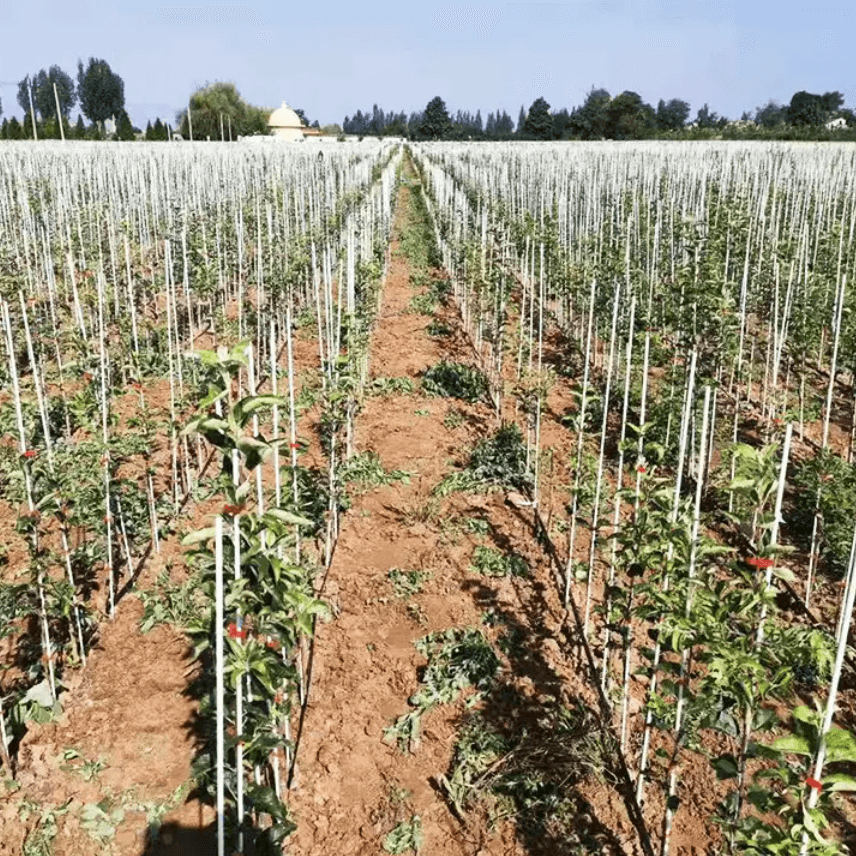

♦ Zaub rack

♦ Fujiman yug tsiaj khib

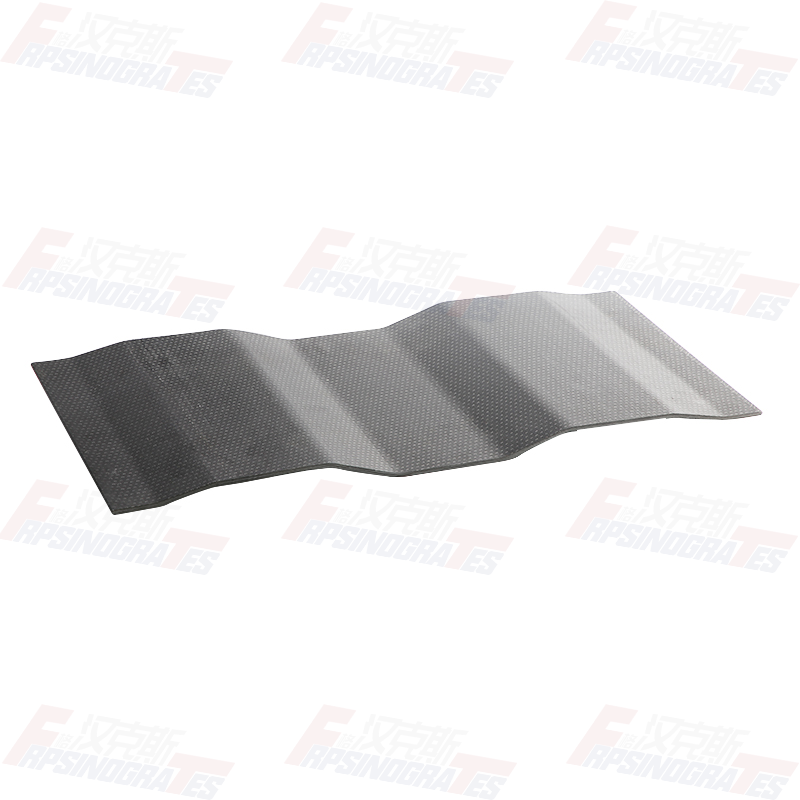

Qhov chaw ntawm FRP pultruded profiles exhibitions: