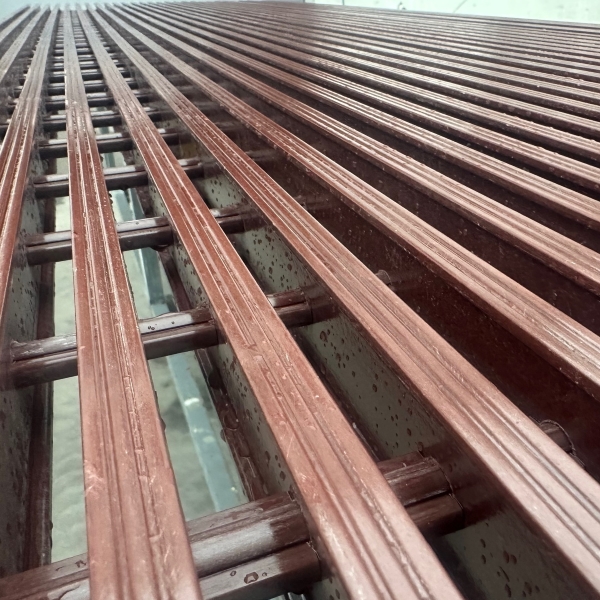

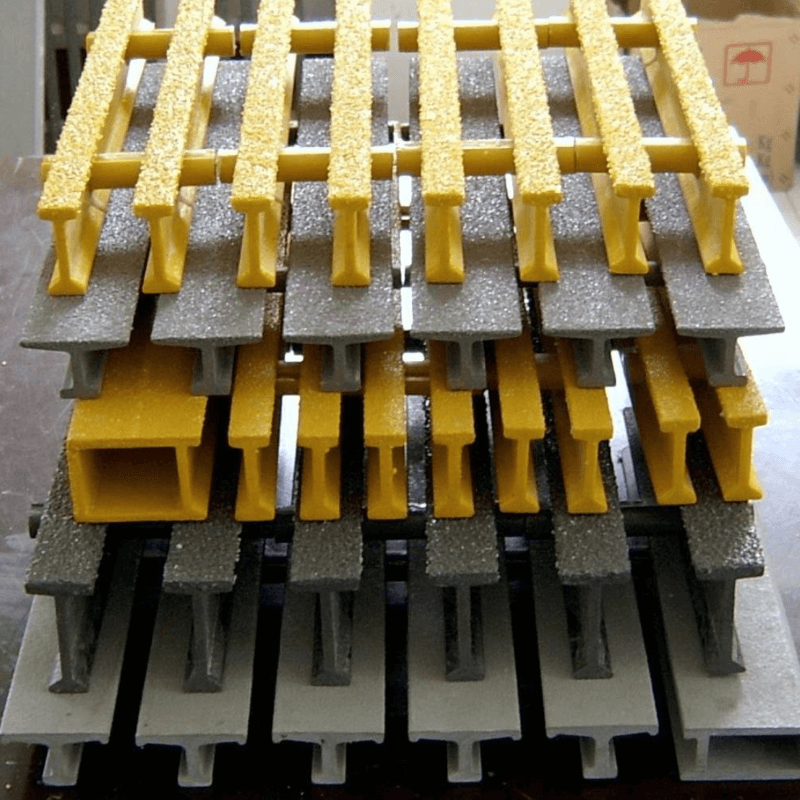

FRP Pultruded Grating Hluav Taws Kub Retardant / Chemical Resistant

Yam khoom ntawm molded FRP Pultruded grating exhibitions:

| Ib-5010 | 50 | 15 | 25 | 10 | 40 | 28.5 Nws |

| ib-5015 | 50 | 15 | 30 | 15 | 50 | 24.2 ib |

| ib-5023 | 50 | 15 | 38 | 23 | 60 | 20.1 |

| T-2510 | 25 | 38 | 43.4 ib | 5.4 | 12 | 15.6 ib |

| T-2515 | 25 | 38 | 50.8 ib | 9.5 ib | 18 | 13.9 Nws |

| T-2520 | 25 | 38 | 50.8 ib | 12.7 ib | 25 | 13.6 |

| T-2530 Nws | 25 | 38 | 61 | 19.7 ib | 33 | 11.2 |

| T-3810 Nws | 38 | 38 | 43.3 ib | 5.2 | 12 | 19.6 ib |

| T-3815 | 38 | 38 | 50.8 ib | 12.7 ib | 25 | 16.7 ib |

| T-3820 Nws | 38 | 38 | 61 | 23 | 38 | 14.3 |

| T-5010 | 50 | 25.4 ib | 38.1 ib | 12.7 ib | 33 | 21.8 ib |

| T-5015 | 50 | 25.4 ib | 50.8 ib | 25.4 ib | 50 | 17.4 ib |

| H-5010 | 50 | 15 | 10 | 10 | 40 | 63 |

| H-5015 | 50 | 15 | 15 | 15 | 50 | 52.3 ib |

| H-5020 | 50 | 15 | 23 | 23 | 60 | 43.6 ib |

| Pultruded Grating hom | Qhov siab (mm) | Sab saum toj dav (mm) | Qhov chaw nruab nrab (mm) | Clearance dav (mm) | Qhib cheeb tsam (%) | Kwv yees qhov hnyav Kg / ㎡ |

| Ib-2510 | 25 | 15 | 25 | 10 | 40 | 17.8 ib |

| Ib-2515 | 25 | 15 | 30 | 15 | 50 | 15.2 |

| Ib-2523 | 25 | 15 | 38 | 23 | 60 | 12.2 |

| ib-3810 | 38 | 15 | 25 | 10 | 40 | 22 |

| ib-3815 | 38 | 15 | 30 | 15 | 50 | 19.1 ib |

| ib-3823 | 38 | 15 | 38 | 23 | 60 | 16.2 |

| Ib-3010 | 30 | 15 | 25 | 10 | 40 | 19.1 ib |

| Ib-3015 | 30 | 15 | 30 | 15 | 50 | 16.1 |

| Ib-3023 | 30 | 15 | 38 | 23 | 60 | 13.1 |

FRP Resins Systems Xaiv:

Resins Option Guide Guide:

| Resin Hom | Resin Option | Cov khoom | Tshuaj tiv thaiv | Hluav taws kub Retardant (ASTM E84) | Cov khoom | Xim Xim | Max kub ℃ |

| Hom P | Phenolic | Tsawg pa luam yeeb thiab Superior Fire Resistance | Zoo heev | Chav Kawm 1, 5 lossis tsawg dua | Moulded thiab Pultruded | Xim Xim | 150 ℃ |

| Hom V | Vinyl Ester | Superior Corrosion Resistance thiab hluav taws kub retardant | Zoo heev | Chav Kawm 1, 25 lossis tsawg dua | Moulded thiab Pultruded | Xim Xim | 95 ℃ |

| Hom I | Isophthalic polyester | Muaj Qib Corrosion Resistance thiab hluav taws kub retardant | Zoo heev | Chav Kawm 1, 25 lossis tsawg dua | Moulded thiab Pultruded | Xim Xim | 85 ℃ |

| Hom O | Ortho | Nruab nrab Corrosion Resistance thiab hluav taws kub retardant | Ib txwm | Chav Kawm 1, 25 lossis tsawg dua | Moulded thiab Pultruded | Xim Xim | 85 ℃ |

| Hom F | Isophthalic polyester | Food Grade Corrosion Resistance thiab Fire Retardant | Zoo heev | Chav Kawm 2, 75 lossis tsawg dua | Moulded | Xim av | 85 ℃ |

| Hom E | Epoxy | Zoo heev corrosion kuj thiab hluav taws kub retardant | Zoo heev | Chav Kawm 1, 25 lossis tsawg dua | Pultruded | Xim Xim | 180 ℃ |

Xim XimRaws li qhov chaw sib txawv thiab kev siv, xaiv cov resins sib txawv, peb kuj tuaj yeem muab qee cov lus qhia!

Phenolic resin (Hom P): Qhov kev xaiv zoo tshaj plaws rau cov ntawv thov uas xav tau cov hluav taws kub retardant thiab cov pa luam yeeb tsawg xws li cov roj refineries, steel factories, thiab pier decks.

Vinyl Ester (Hom V): tiv taus cov tshuaj lom neeg nruj heev uas siv rau kev siv tshuaj lom neeg, pov tseg kev kho mob, thiab cov nroj tsuag tsim.

Isophthalic resin (Hom I): Ib qho kev xaiv zoo rau cov ntawv thov uas muaj tshuaj txau thiab nchuav yog ib qho tshwm sim.

Khoom noj khoom haus qib Isophthalic resin (Hom F): Qhov zoo tshaj plaws rau cov khoom noj khoom haus thiab dej haus kev lag luam uas raug rau ib puag ncig huv si.

General Purpose Orthothphalic resin (Hom O): Kev lag luam hloov pauv rau cov khoom siv yas ester thiab isophthalic resins.

Epoxy Resin (Hom E):muab cov cuab yeej zoo heev thiab qaug zog ua haujlwm, noj qhov zoo ntawm lwm cov resins. Pwm cov nqi zoo ib yam li PE thiab VE, tab sis cov nqi khoom kim dua.

Product Capacities Test Laboratory:

Cov cuab yeej siv tshuaj ntsuam xyuas zoo rau FRP pultruded profiles thiab FRP molded gratings, xws li kev sim flexural, tensile tests, compression tests, thiab destructive tests. Raws li cov neeg siv khoom xav tau, peb yuav ua qhov kev ua tau zoo & kev ntsuas lub peev xwm ntawm FRP cov khoom, khaws cov ntaub ntawv kom ruaj ntseg zoo rau lub sijhawm ntev. Peb tuaj yeem xyuas kom meej tias qhov zoo tuaj yeem ua rau cov neeg siv khoom xav tau ruaj khov kom tsis txhob muaj teeb meem tom qab muag khoom.

SINOGRATS @ FRP Pultrusion Grating

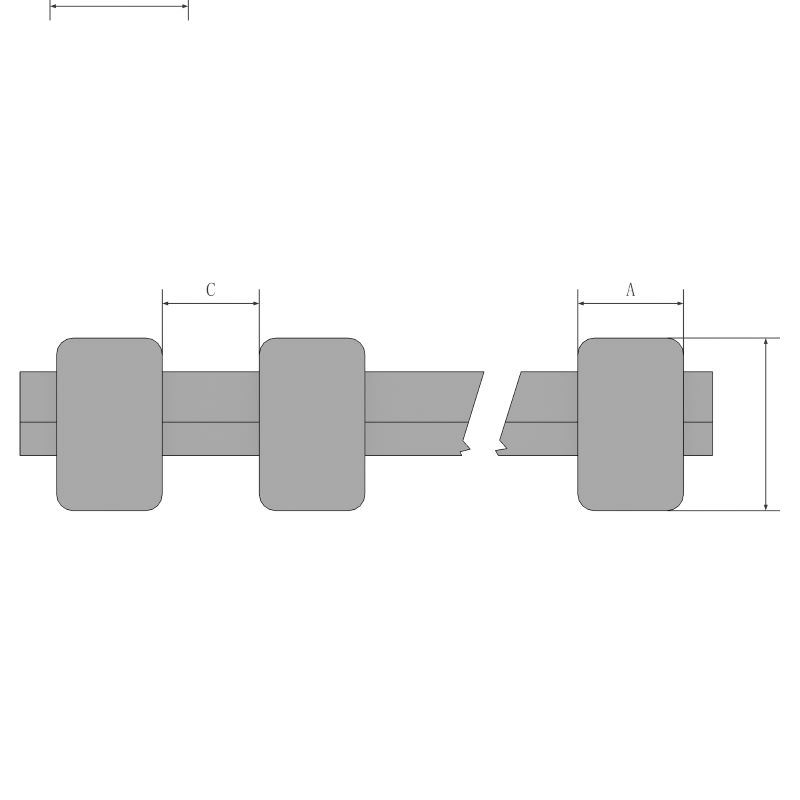

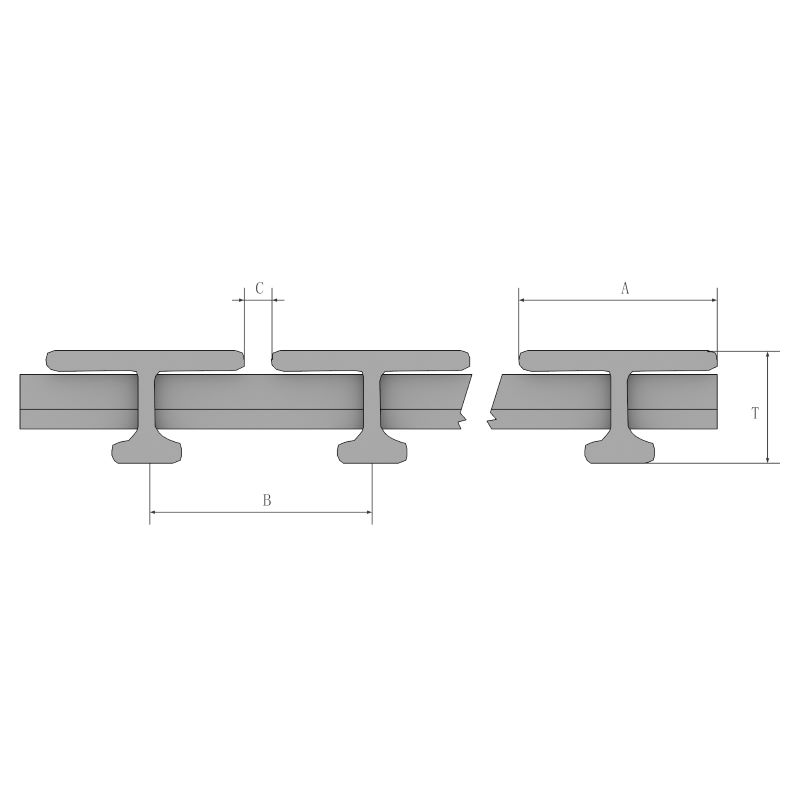

Pultrusion txheej txheem yog txheej txheem tsim khoom tsim kom ntev ntev ntawm cov khoom siv hluav taws xob muaj zog polymer nrog cov ntu ntu tas li. Cov ntaub ntawv raw yog cov kua resin sib tov (resins, fillers thiab tshwj xeeb additives) thiab saj zawg zog textile reinforcing fiberglass rovings. Cov txheej txheem cuam tshuam nrog rub cov ntaub ntawv raw (tshwj tsis yog thawb, ib yam li cov ntaub ntawv hauv extrusion) los ntawm cov hlau rhuab sib sau tuag uas siv cov cuab yeej rub tawm tas li.

Cov ntaub ntawv ntxiv yog nyob rau hauv cov ntaub ntawv txuas ntxiv xws li yob ntawm fiberglass mats thiab doffs ntawm fiberglass rovings. Raws li cov khoom siv ntxiv yog saturated nrog cov resins sib tov ("ntub-tawm") hauv cov dej da dej thiab rub los ntawm kev tuag, gelation, los yog hardening, ntawm cov resin yog pib los ntawm tshav kub los ntawm qhov tuag thiab ib tug nruj, kho profile yog tsim uas sib haum mus rau qhov zoo ntawm cov tuag.

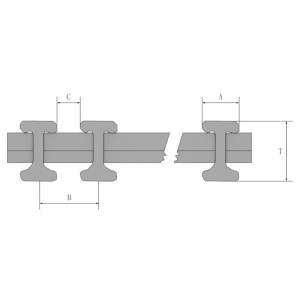

FRP Pultrusion grating tuaj nyob rau hauv peb pawg: I-Shape tuav, T-Shape tuav, thiab High-Load tuav rau Hnyav-duty daim ntaub ntawv.