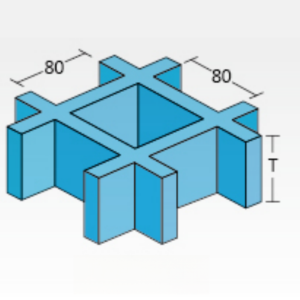

FRP/GRP stiklšķiedras pretizturīgs klājs ar režģi

PRODUKTA APRAKSTS

VEIDLAPAS SPECIFIKĀCIJAS TABULA

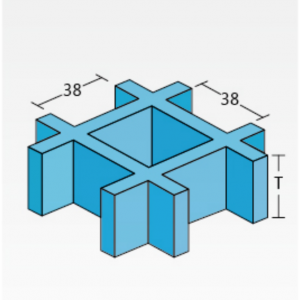

| AUGSTUMS (mm) | STIEŅA BIEZUMS (mm AUGŠĀ/APAKŠĀ) | TĪKLA ACS IZMĒRS (MM) | PIEEJAMIE PANEĻA IZMĒRI (MM) | SVARS (KG/m²) | ATVĒRŠANAS LIKME (%) |

| 13 | 6,0/5,0 | 38*38 | 1220*2440/1220*3660/1220*4000/1000*3000/921*3055 | 6 | 78 |

| 14 | 6,0/5,0 | 38*38 | 1220*2440/1220*3660/1220*4000/1000*3000/921*3055 | 6.5 | 78 |

| 15 | 6,0/5,0 | 38*38 | 1220*2440/1220*3660/1220*4000/1000*3000/921*3055 | 7 | 78 |

| 20 | 6,0/5,0 | 38*38 | 1220*2440/1220*3660/1220*4000/1220*4038/1000*2000/1000*3000/921*3055 | 9.8 | 65 |

| 25 | 6,5/5,0 | 38*38 | 1220*2440/1220*3660/1220*4000/1220*4038/1000*2000/1000*3000/915*3050/921*3055 | 12,5 | 68 |

| 25 | 7,0/5,0 | 38*38 | 1000*4000 | 12,5 | 68 |

| 30 | 6,5/5,0 | 38*38 | 1220*2440/1220*3660/1220*4000/1220*4038/1000*2000/1000*3000/921*3055 | 14.6 | 68 |

| 30 | 7,0/5,0 | 38*38 | 1000*4000/1220*4000 | 16 | 68 |

| 38 | 6,5/5,0 | 38*38 | 1220*2440/1220*3660/1220*4000/1220*4920/1000*2000/1000*3000/1000*4038/921*3055/915*3050/1524*3660 | 19,5 | 68 |

| 38 | 7,0/5,0 | 38*38 | 1000*4000/1220*4000 | 19,5 | 68 |

| 63 | 12,0/8,0 | 38*38 | 1530*4000 | 52 | 68 |

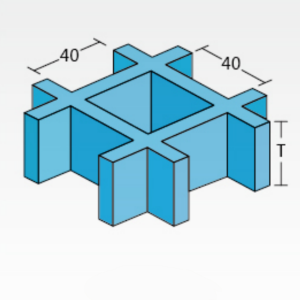

| 25 | 6,5/5,0 | 40*40 | 1007*3007/1007*2007/1007*4047/1247*3007/1247*4047/1207*3007 | 12,5 | 67 |

| 25 | 7,0/5,0 | 40*40 | 1007*4007 | 12 | 67 |

| 30 | 6,5/5,0 | 40*40 | 1007*3007/1007*2007/1007*4047/1247*3007/1247*4047/1207*3007 | 14.6 | 67 |

| 30 | 7,0/5,0 | 40*40 | 1000*4000 | 15 | 67 |

| 38 | 7,0/5,0 | 40*40 | 1007*2007/1007*3007/1007*4047/1247*3007/1247*4047/1207*3007 | 19.2 | 67 |

| 40 | 7,0/5,0 | 40*40 | 1007*2007/1007*3007/1007*4007/1007*4047/1207*3007/1247*3007/1247*4047 | 19,5 | 67 |

| 50 | 7,0/5,0 | 40*40 | 1007*2007/1007*3007/1007*4047/1207*3007/1247*3007/1247*4047 | 25,0 | 58 |

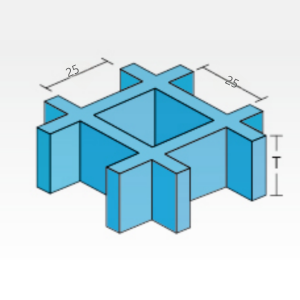

| 30 | 7,0/5,0 | 25*25 | 1000*4000 | 16 | 58 |

| 40 | 7,0/5,0 | 25*25 | 1200*4000 | 22 | 58 |

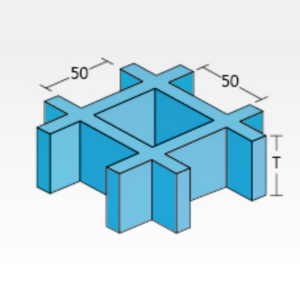

| 50 | 8,0/6,0 | 50*50 | 1220*2440/1220*3660/1000*2000/1000*3000 | 24 | 78 |

| 50 | 7,2/5,0 | 50*50 | 1220*2440/1220*3660/1000*4000/1000*3000 | 21 | 78 |

| 13 | 10,0/9,0 | 80*80 | 1530*3817/730*1873 | 5.5 | 81 |

| 14 | 10,0/9,0 | 80*80 | 1530*3817/730*1873 | 6 | 81 |

| 15 | 10,0/9,0 | 80*80 | 1530*3817/730*1873 | 6.5 | 81 |

FRP formētas režģa virsmas izvēles:

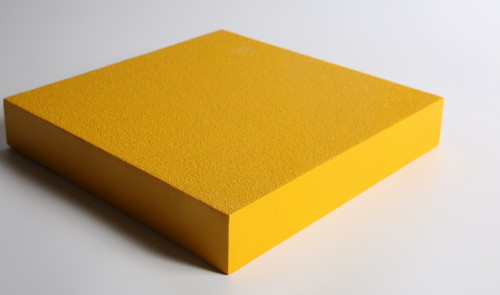

Plakana augšdaļa

Dimanta augšdaļa

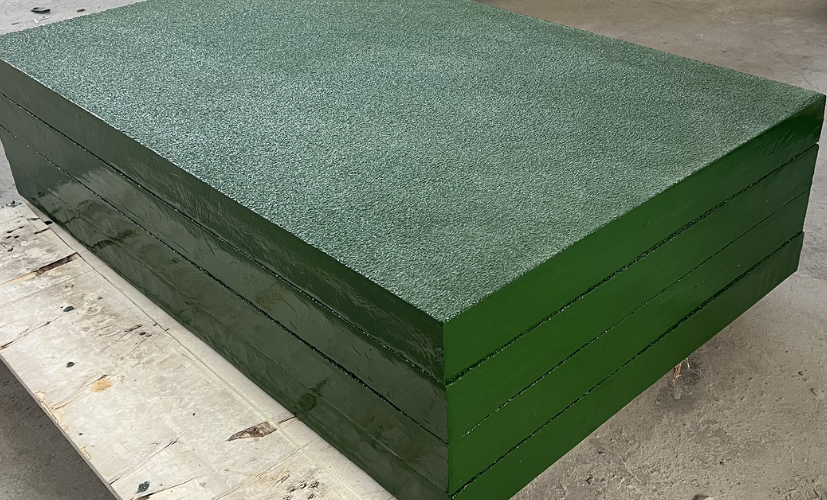

Grants virsma

● Plakana virsma

Pievienota formēta režģa ar plakanu augšējo plāksni

● Dimanta augšdaļa

Plakana augšējā plāksne ar paceltu protektora rakstu maksimālai saķerei. Dimanta virsmas biezums 3 vai 5 mm. Plāksnes biezums palielina režģa kopējo biezumu.

● Grit Top

Grit virsējā plāksne ar biezumu 3 mm vai 5 mm, plāksnes biezums palielina režģa kopējo biezumu

FRP sveķu sistēmu izvēles:

Fenola sveķi (P tips)Labākā izvēle lietojumiem, kuros nepieciešama maksimāla ugunsdrošība un zema dūmu emisija, piemēram, naftas pārstrādes rūpnīcām, tērauda rūpnīcām un molu klājiem.

Vinilesteris (V tips)iztur stingras ķīmiskās vides, ko izmanto ķīmiskajās, atkritumu apstrādes un lietuvju rūpnīcās.

Izoftaliskā sveķi (I tips)I tips ir augstākās kvalitātes izoftaliskā poliestera sveķi. Tā ir populāra izvēle lielākajai daļai pielietojumu, pateicoties labajām korozijas izturības īpašībām un relatīvi zemajām izmaksām. Šāda veida sveķus visbiežāk izmanto pielietojumos, kur pastāv spēcīgu ķīmisku vielu šļakatu vai izliešanas iespēja.

Universāla ortofāla sveķu masa (O tips)ekonomiskas alternatīvas vinilestera un izoftaliskā sveķu produktiem.

Pārtikas kvalitātes izoftalāta sveķi (F tips)Ideāli piemērots pārtikas un dzērienu rūpniecības rūpnīcām, kas pakļautas stingriem tīrības standartiem.

Epoksīdsveķi (E tips):piedāvā ļoti augstas mehāniskās īpašības un noguruma izturību, izmantojot citu sveķu priekšrocības. Veidnes izmaksas ir līdzīgas PE un VE, bet materiālu izmaksas ir augstākas.

Sveķu opciju ceļvedis:

| Sveķu tips | Sveķu variants | Īpašumi | Ķīmiskā izturība | Ugunsdrošs (ASTM E84) | Produkti | Pielāgotas krāsas | Maksimālā temperatūra ℃ |

| P tips | Fenols | Zema dūmu koncentrācija un izcila ugunsizturība | Ļoti labi | 1., 5. vai zemāka klase | Formēts un pultrēts | Pielāgotas krāsas | 150 ℃ |

| V tips | Vinila esteris | Izcila izturība pret koroziju un ugunsdrošība | Lieliski | 1. klase, 25 vai mazāk | Formēts un pultrēts | Pielāgotas krāsas | 95 ℃ |

| I tips | Izoftaliskais poliesters | Rūpnieciskās klases korozijas izturība un ugunsdrošība | Ļoti labi | 1. klase, 25 vai mazāk | Formēts un pultrēts | Pielāgotas krāsas | 85 ℃ |

| O tips | Orto | Vidēja izturība pret koroziju un ugunsdrošība | Normāls | 1. klase, 25 vai mazāk | Formēts un pultrēts | Pielāgotas krāsas | 85 ℃ |

| F tips | Izoftaliskais poliesters | Pārtikas kvalitātes korozijas izturība un ugunsdrošība | Ļoti labi | 2. klase, 75 vai mazāk | Formēts | Brūns | 85 ℃ |

| E tips | Epoksīdsveķi | Lieliska izturība pret koroziju un ugunsdrošība | Lieliski | 1. klase, 25 vai mazāk | Pultrudēts | Pielāgotas krāsas | 180 ℃ |

Atkarībā no dažādām vidēm un pielietojumiem, izvēlētajiem dažādiem sveķiem, mēs varētu sniegt arī dažus padomus!

GADĪJUMU IZPĒTES

Mūsu ar FRP (stiklšķiedras pastiprinātas plastmasas) pārklātais režģis apvieno strukturālo izturību ar izcilu ķīmisko izturību, padarot to par ideālu izvēli skarbiem apstākļiem.

Pārsega panelis nodrošina materiālu, struktūru un funkcionalitāti, piedāvājot izcilu drošību, izturību un dzīves cikla izmaksu ietaupījumus kritiski svarīgām rūpnieciskām lietojumprogrammām.

Tipiski pielietojumi

◼ Ķīmiskās pārstrādes rūpnīcas

◼ Jūras platformas un jūras iekārtas

◼ Notekūdeņu attīrīšanas iekārtas

◼ Pārtikas un farmācijas uzņēmumi

◼ Elektriskās apakšstacijas

◼ Gājēju celiņi un drošības platformas