FRP / GRP PULTNELA FORNANOL Tennels Terene ea Forrolass le Checrant Ass

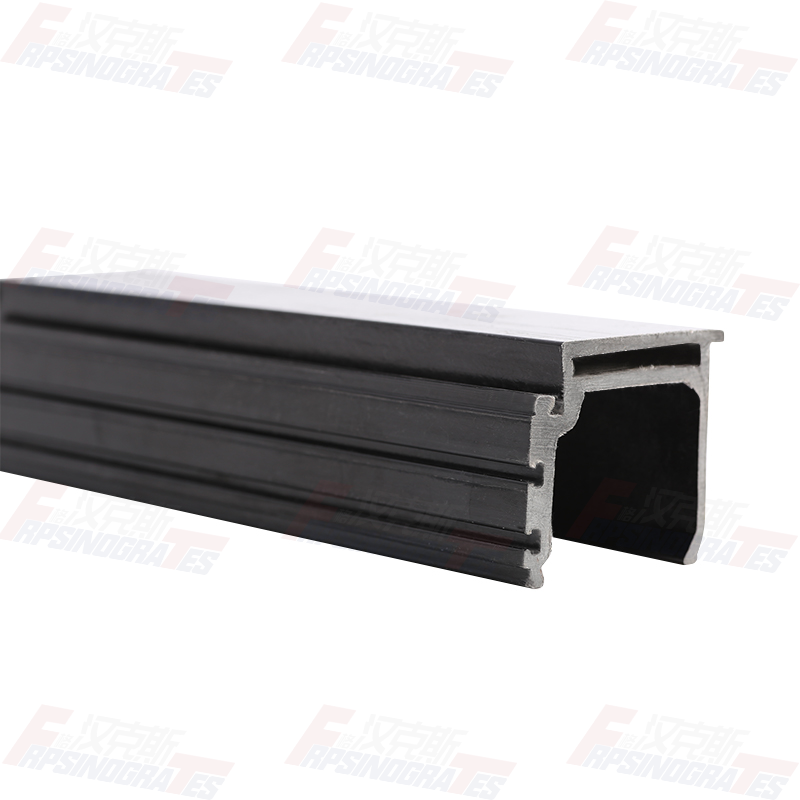

Fiberglass Tenglass Texnels Melds:

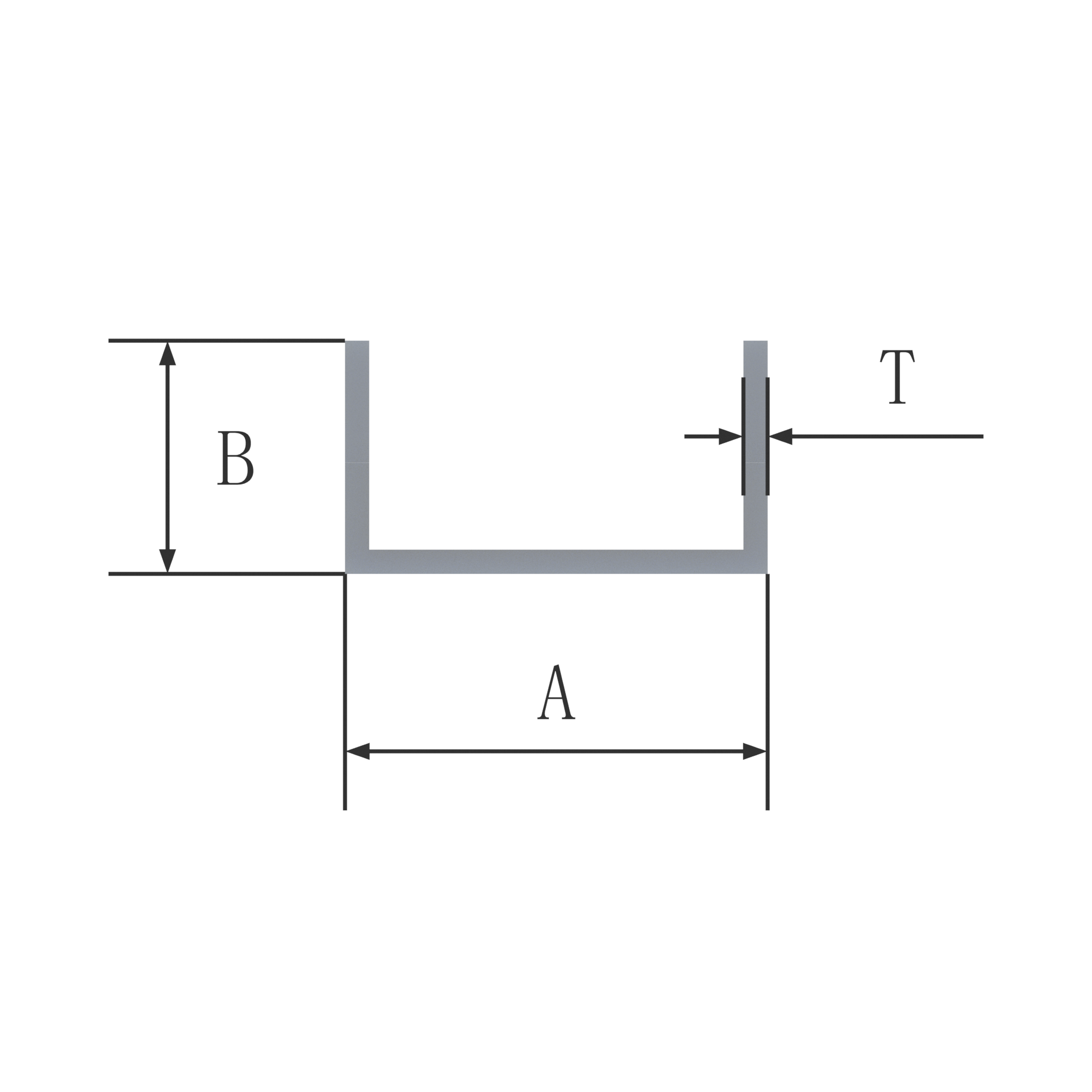

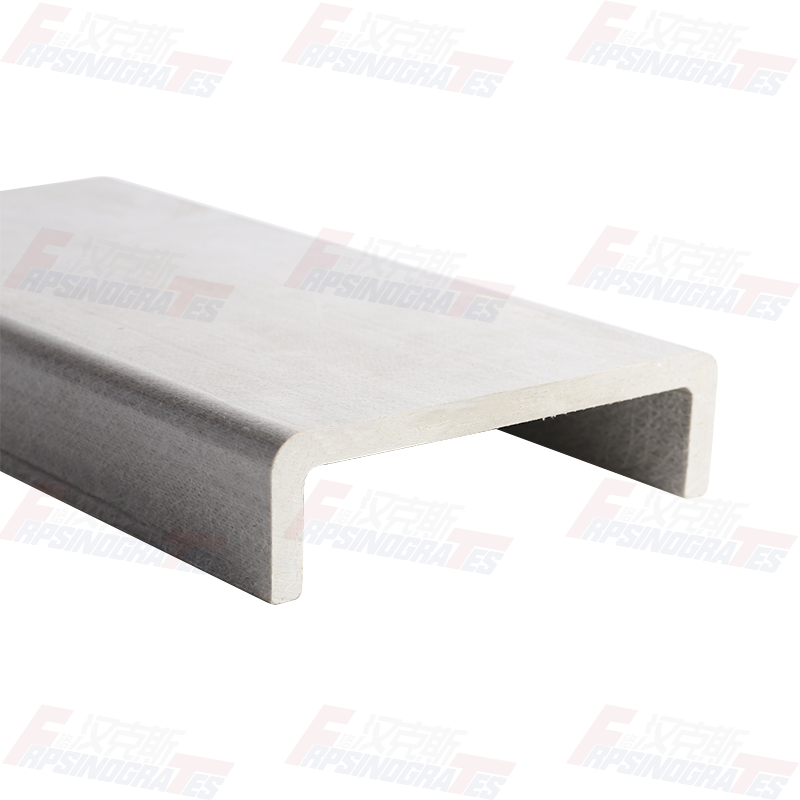

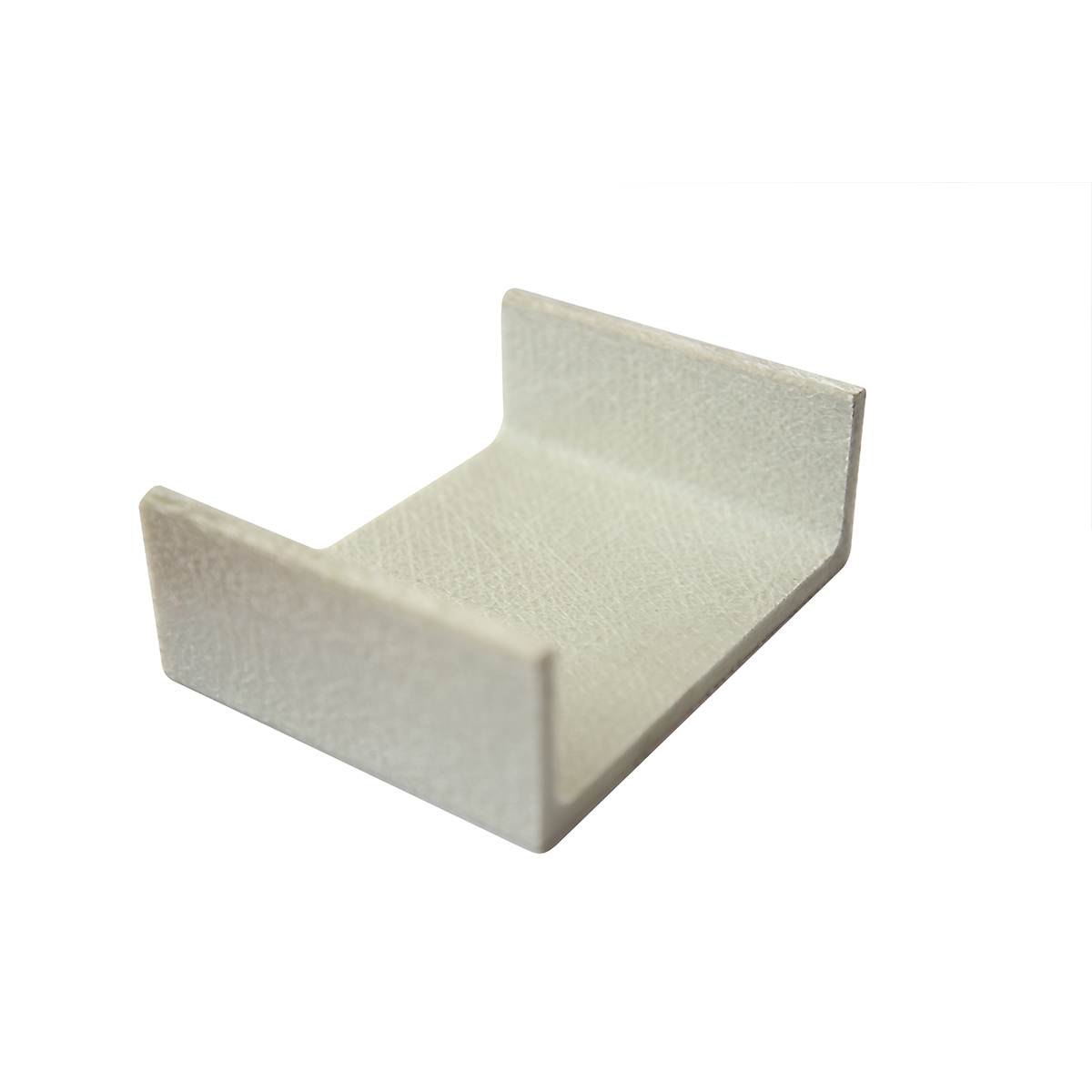

| SerialLintho | Axbxt (mm) | Boima g / m | SerialLintho | Axbxt (mm) | Boima g / m |

| 1 | 38x29x3.0 | 393 | 32 | 100X35x5.0 | 1500 |

| 2 | 38.5x203.2 | 420 | 33 | 100X40x5.0 | 1575 |

| 3 | 40x203.5 | 480 | 34 | 100x50x6.0 | 2080 |

| 4 | 40x222x5.0 | 703 | 35 | 101x29x6.3 | 1700 |

| 5 | 44x23.4x4.0 | 610 | 36 | 101x35x5.5 | 1670 |

| 6 | 44x28x2.5 | 496 | 37 | 102x44x4x4.8 | 1650 |

| 7 | 44x28x3.0 | 515 | 38 | 112x46x5.0 | 1790 |

| 8 | 45x15x2.5 | 350 | 39 | 112x50x6.0 | 2220 |

| 9 | 45x25x2.5 | 450 | 40 | 116x65x7.0 | 2850 |

| 10 | 48x30x3.2 | 544 | 41 | 120x40x5.0 | 1775 |

| 11 | 50x30x5.0 | 852 | 42 | 120x40x10 | 3350 |

| 12 | 50.8x14x3.2 | 425 | 43 | 120x41x4.5 | 1610 |

| 13 | 54x38x6.4 | 1388 | 44 | 127x422x6.0 | 2360 |

| 14 | 55x28x3.5 | 673 | 45 | 127x45x6.5 | 2332 |

| 15 | 55x28x4.0 | 745 | 46 | 127x45x10 | 3700 |

| 16 | 59x38x4.76 | 1105 | 47 | 139x38x6.3 | 2390 |

| 17 | 60x40x5.0 | 1205 | 48 | 150x40x10 | 3800 |

| 18 | 60x50x5.0 | 1420 | 49 | 150x422x9.5 | 3660 |

| 19 | 63x25x4.0 | 790 | 50 | 150x7x7x5.0 | 2760 |

| 20 | 70x26x3.0 | 680 | 51 | 152x43xx9.5 | 3850 |

| 21 | 70x30x3.5 | 775 | 52 | 175x75x10 | 5800 |

| 22 | 70x30x3.8 | 840 | 53 | 180x70x4.0 | 2375 |

| 23 | 70x30x4.5 | 1020 | 54 | 190x555x6.3 | 3400 |

| 24 | 70x30x5.0 | 1050 | 55 | 190.5x35x5.0 | 2417 |

| 25 | 77x28x4.0 | 950 | 56 | 200x50x6.0 | 3300 |

| 26 | 80x30x3.0 | 765 | 57 | 200x60x10 | 5700 |

| 27 | 80x30x4.6 | 1130 | 58 | 200x70x10 | 6400 |

| 28 | 88x35x5.0 | 1325 | 59 | 203x56x9.5 | 5134 |

| 29 | 89x38x4.7 | 1340 | 60 | 240x72.8.0 | 5600 |

| 30 | 89x38x6.3 | 1780 | 61 | 254x70x12.7 | 8660 |

| 31 | 90x35x3.0 | 1520 |

Sinograte @ Gfrp Plultrusion:

•Leseli

• Tlhahlobo

• khanyetso ea lik'hemik'hale

• Mollo oa Mollo

• Libaka tsa Anti-Slip

• e bonolo bakeng sa ho kenya

• litšenyehelo tse tlase tsa tokiso

• Ts'ireletso ea UV

• Matla a mabeli a matla

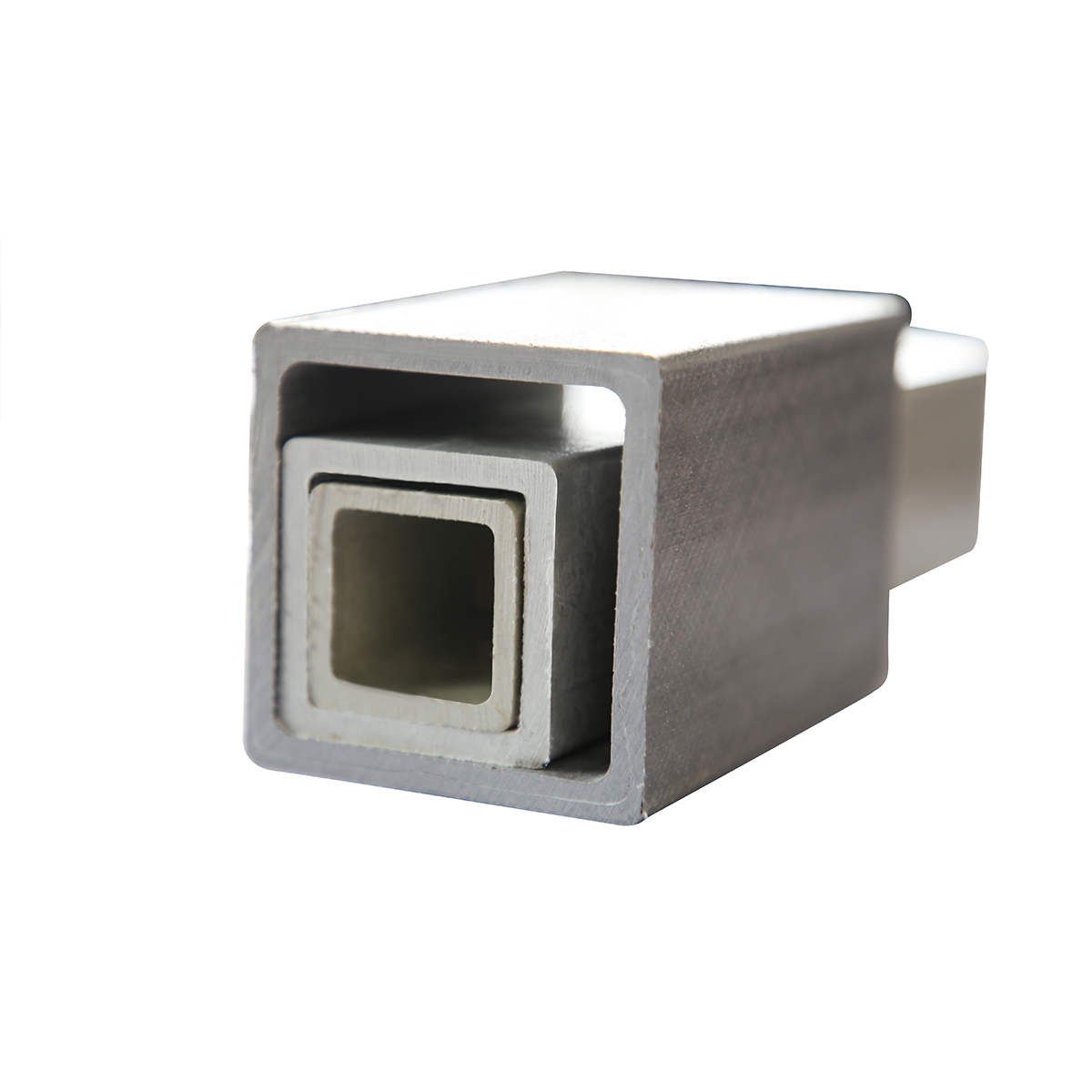

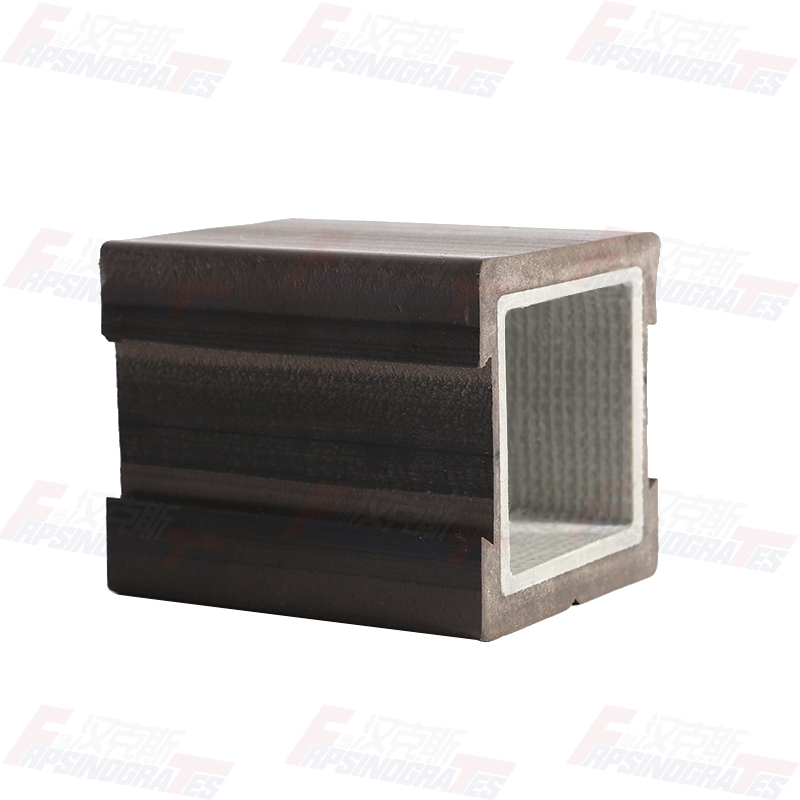

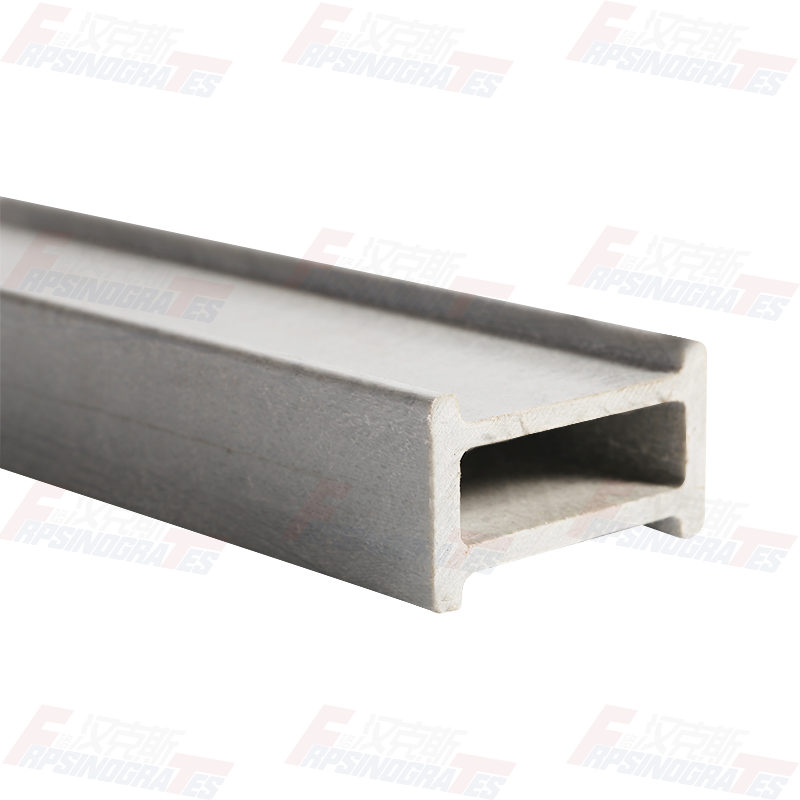

Ts'ebetso e ntle e tsoelang pele e ntlafalitsoeng e le ngoe e tsoelang pele moo khalase e ntseng e tsamaea "ka ho futhumatsoa ke ho futhumatsoa ho etsa hore ho be le sebopeho sa boemo ba bophelo.

Prulrsion ke ts'ebetso e tsoelang pele ebile e le ntho e iketsang, e theko e boima ho tlhahiso e phahameng ea phetoho e matha likarolo tsa nakoana tsa sefapano. Mefuta e tloaelehileng ea pollupe e kenyelletsa i-sbams Ts'ebetso ea pollusion e itšetleha ka sisteri e tšosang e kang ea ho hula fiber ka bath bath bath bath bate, le tšepe e futhumetseng e shoa. Ha fiber e kolobisitsoeng e feta ho des (e thehiloe ka sebopeho sa profil e lakatsehang) e kopantsoe le ho fodwa. PALE EA BOPHELO E MOLEMO E FIHLA LE HO FIHLELA LE LITLHAKISO TSE KHOLO tse hlahisoang ke lebelo la mohala.

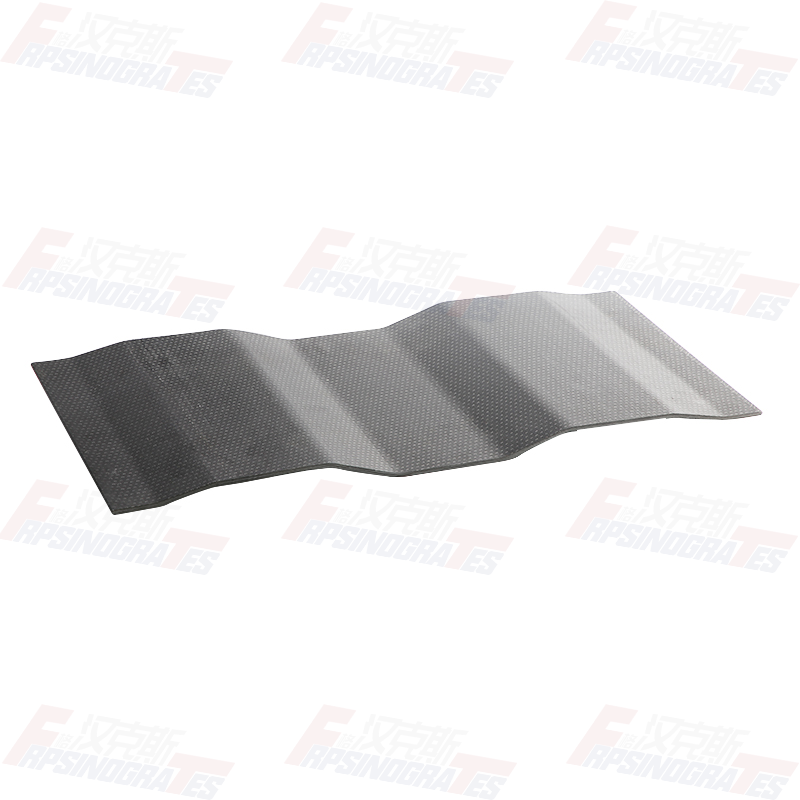

Litsamaiso tse ling tsa metsi tse bolotsana li akhela polokelo ka kotloloho le likhoele tse ngata tsa fiber le li-fiber tsa fiber tse ngata li ka roaloa le ho shoa ka mokhoa o le mong le mahaha a mangata. Ho theha likarolo tse thata kapa tse ngata tse ngata, fiber e kolobisitsoeng e pota-potile meket e futhumetseng e neng e futhumetse tse futhumetseng tse futhumetseng tse fetisang lijong. Haeba matla a sebopeho a axis a hlokahala, mat le / kapa masela a halikiloeng a ka kenngoa ka har'a sephutheloana sa thepa pele se kena ho shoa. Pultrusion applications typically uses fiberglass and thermoset resins such as polyester, vinyl ester, epoxy, and phenolic.Setšoantšo sa Carbon'me litsela tse ling tse halikiloeng le tse hōletsoeng li ka sebelisoa ho latela litlhoko tsa ts'ebetso tsa sehlahisoa sa pheletso.

Maikutlo a polpi a pohliselitsoeng:

Ho latela boholo ba lihlahisoa tsa FRP le tikoloho e fapaneng, ho khetha likhalase tse fapaneng ho ka fihlela ts'ebetso e phahameng ho boloka litšenyehelo ho isa bohōleng bo itseng.

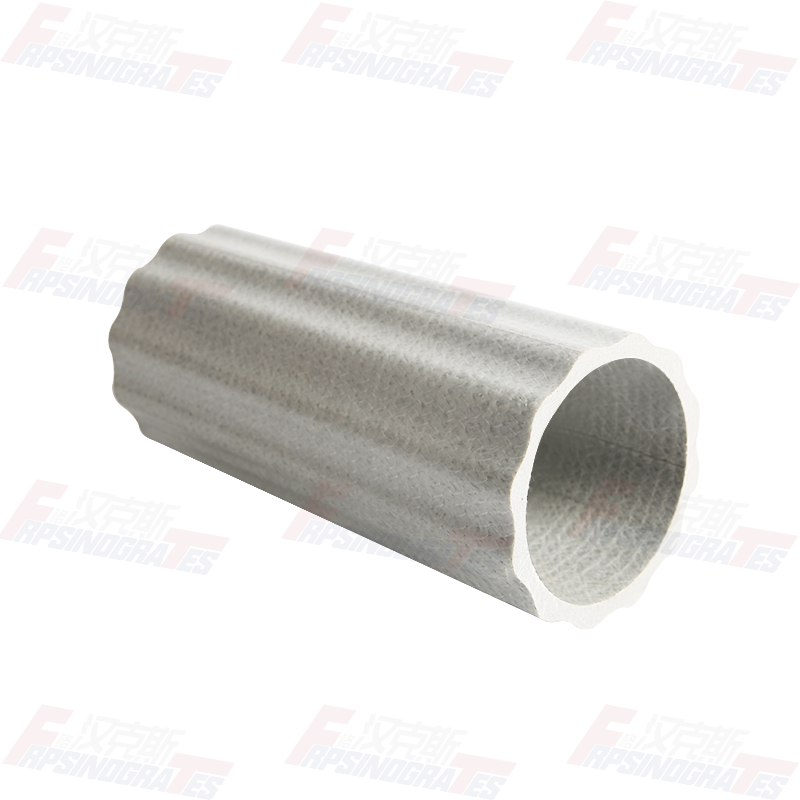

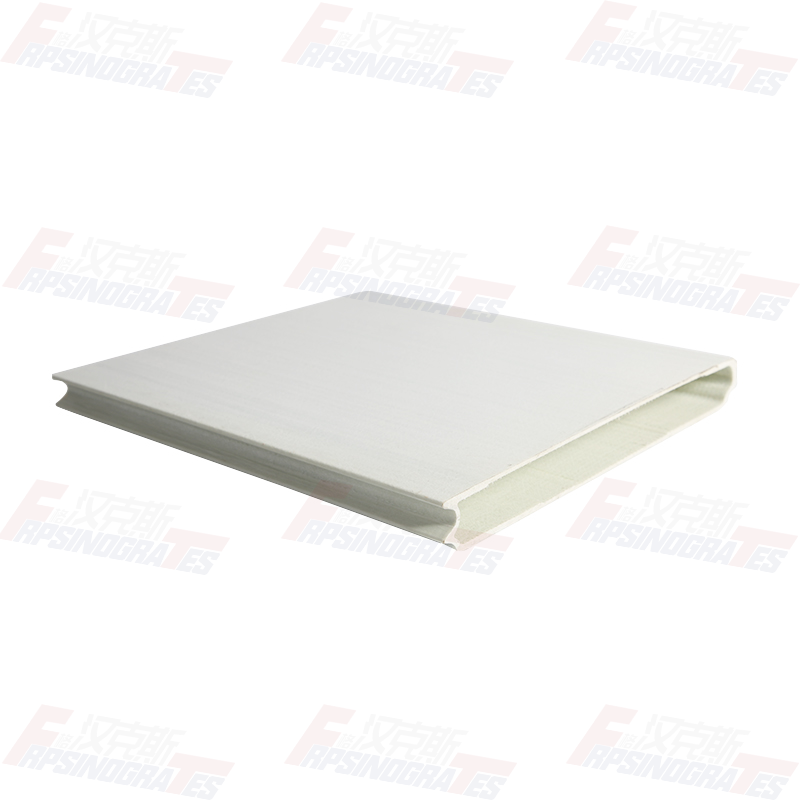

Metsi a silafetseng a silafetseng a silafalang:

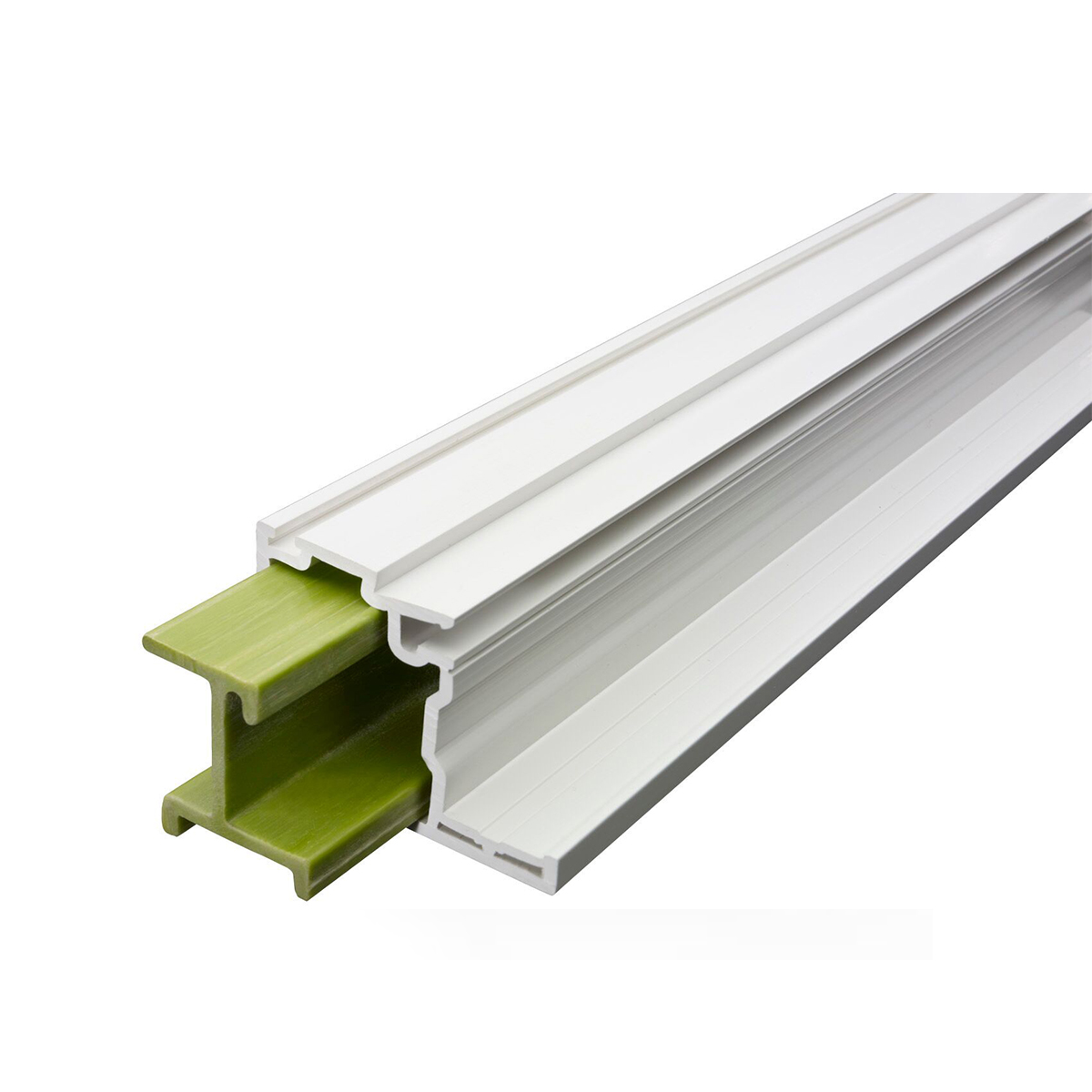

Vils e sa khaotseng ea maiketsetso e tsoelang pele ke ea pele e sebelisoa hangata. Bokaholimo bo tsoelang pele bo hlophisehileng bo ubeloa ke lesela la silika ka ho utloa bohloko bo tsoelang pele. E ka netefatsa matla ha a ntse a etsa hore bokaholimo bo holimo le bo bobebe bo be bobebe. Ha u ama sehlahisoa, matsoho a motho a ke ke a hlatsuoa ke fiber ea khalase. Theko ea boemo bona e phahameng haholo. Ka kakaretso, e sebelisoa libakeng tseo batho ba anngoeng ke literata tsa letsoho, molo o matlafatsang, o nyoloha ka lisebelisoa, le libaka tsa boikhathollo. Karolo e kholo ea bana ba anti -ultraviotraviot e tla eketsoa nakong ea tlhahiso ea tlhahiso. E ka netefatsa hore ha e fele nako e telele ebile e na le ts'ebetso e ntle e khahlanong le eona.

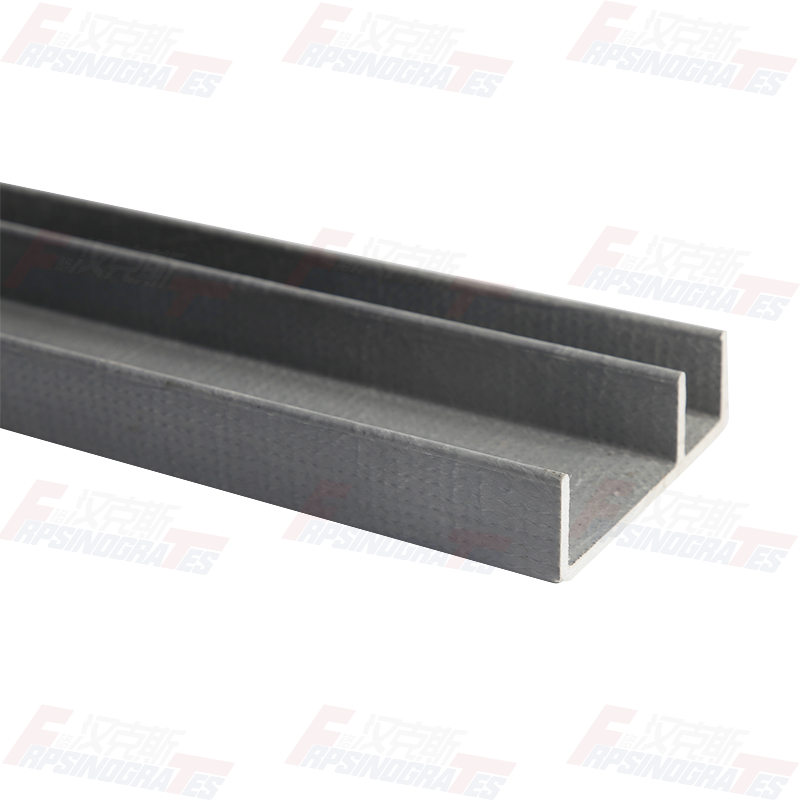

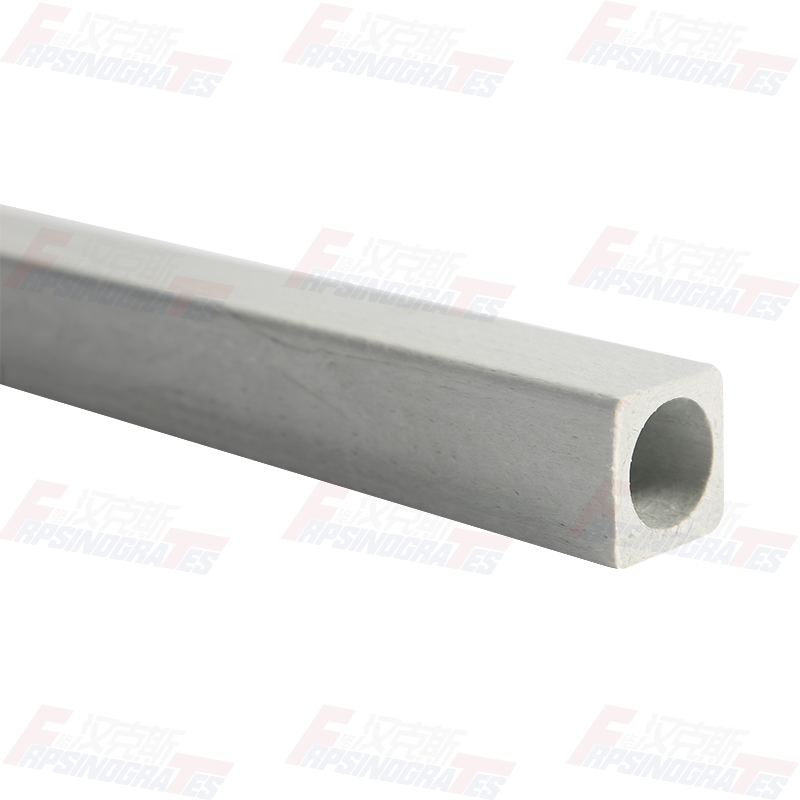

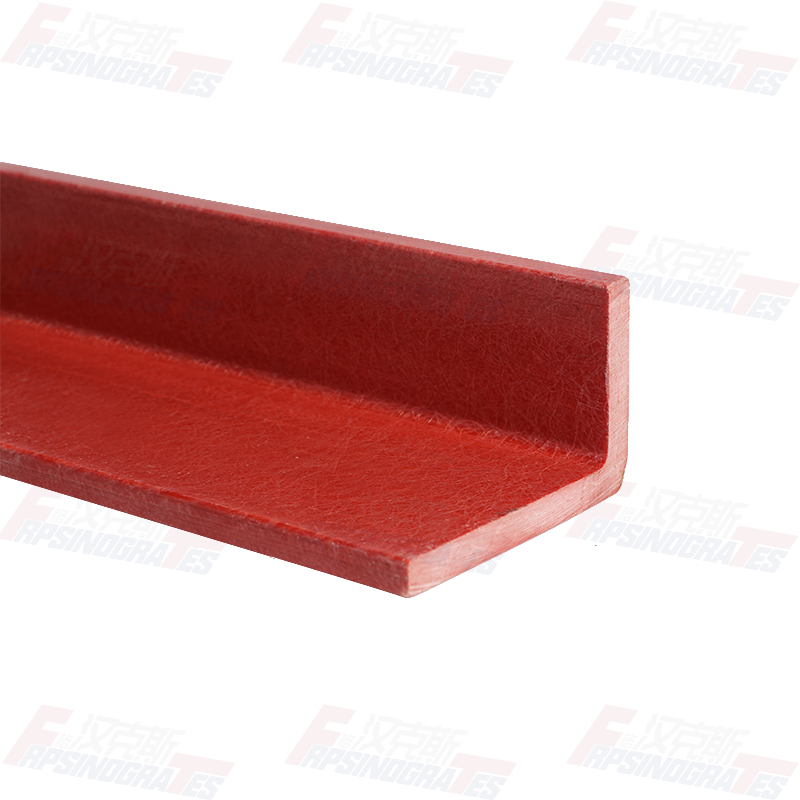

Li-mats tse tsoelang pele:

Mets e tsoelang pele e tsoela pele ke likarolo tse tloaelehileng tse sebelisoang khafetsa nakong e ntle e hlahisoang ke likhau tse kholo. Khoele e tsoelang pelet e tsoelang pele e na le matla a phahameng le matla ohle. Ka kakaretso e sebelisoa ka litšiea tse kholo tsa sebopeho le libalaka. Bokaholimo ba mat strand e tsoelang pele e mpe haholo. Ka kakaretso e sebelisoa karolong e tšehetsang ea indasteri ho nkela tšepe le aluminium sebakeng sa khanyetso ea lihlahla. Ts'ebeliso ea li-profiles tse kholo tsa -scale li sebelisoa meahong eo batho ba sa ame ka eona hangata. Mofuta oa mofuta ona o na le ts'ebetso e ntle ea litšenyehelo. E loketse lits'ebetso tse kholo tsa -scale li le boenjiniere. E ka fokotsa litšenyehelo tsa tšebeliso le ho netefatsa ts'ebetso ea sehlahisoa.

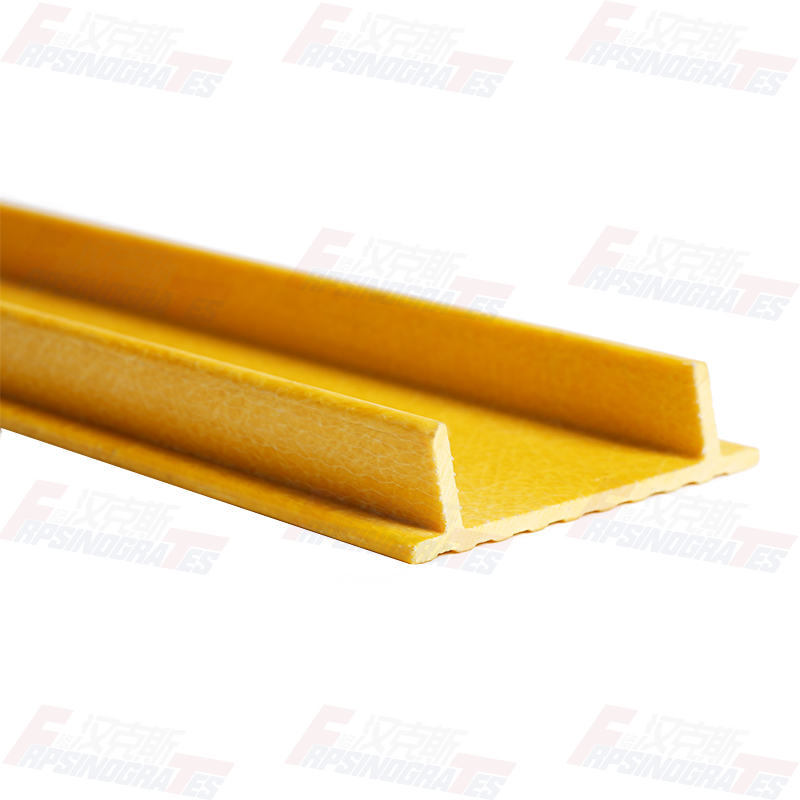

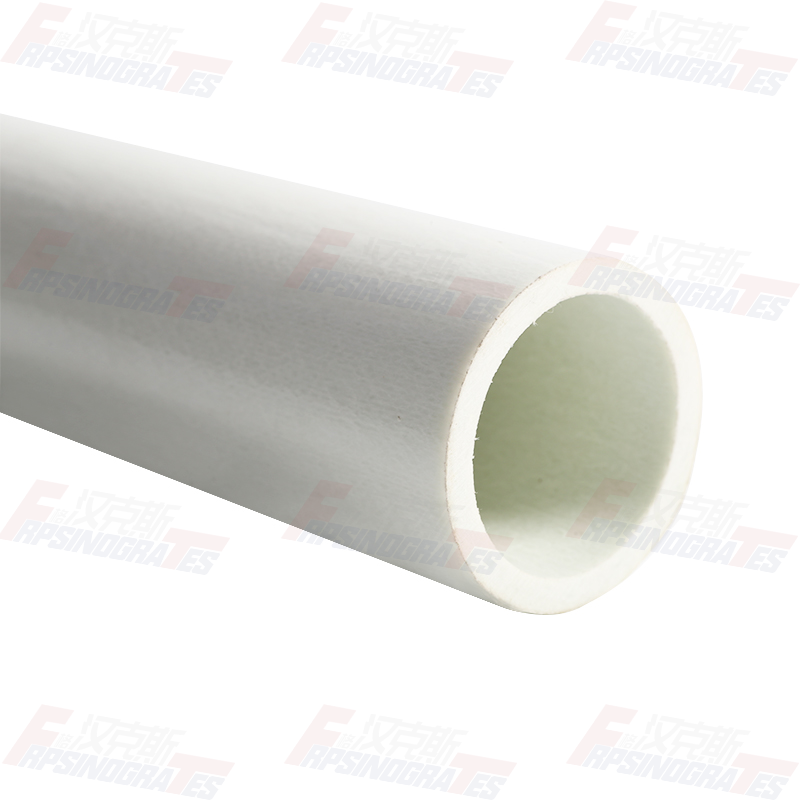

Metsoako e tsoelang pele ea sehlopha:

Ntja e tsoelang pele ea 'masela e tsoelang pele ea fiberglass e lahliloeng ea fiberglass e entsoe ka methapo e mengata le limmapa tse telele tse tsamaeang le ponahalo e ntle le ponahalo e ntle. E ka thusa ka katleho ho fokotsa litšenyehelo. Ke khetho ea moruo ka ho fetisisa haeba e na le lintho tse ngata tse phahameng. E ka boela ea sebelisoa ho boenjiniere ba ha ba hanang. E ka fana ka molemo o matla le ho ba le tšireletso ea batho.

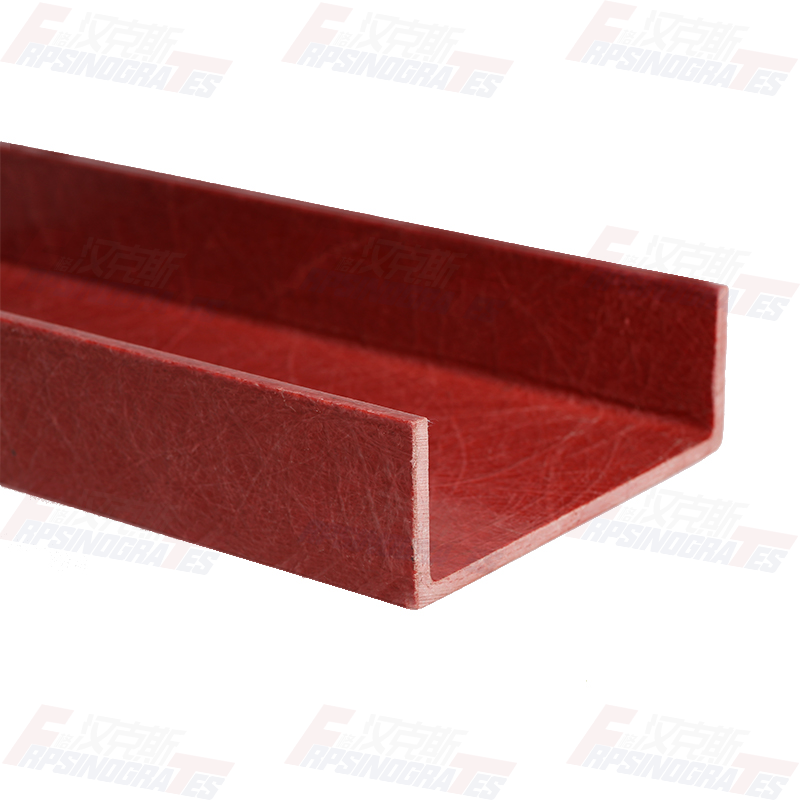

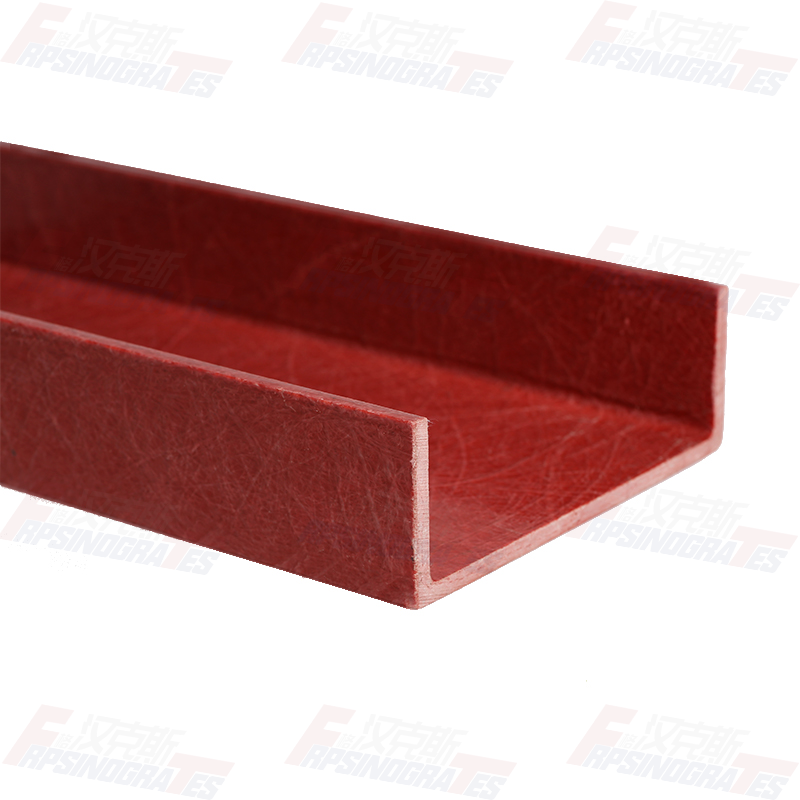

Li-narese tsa paro ea patsi tse sa sebetseng hantle tsa mapolanka:

Li-radio tsa mapolanka tsa mapolanka tsa patsi ea li-syonthetic li na le mofuta o le mong oa fiberglass lesela le thellisang

E na le ts'ebetso e ntle ea matla e tšoanang le lihlahisoa tsa patsi. Ke sebaka sa lisebelisoa tsa patsi joalo ka libaka tsa naha, li-terata, terata ea villa, ha ho bonolo ho baleha, 'me ha ho bonolo ho baleha le ho putlama ha litlhokahalo tsa lihlahisoa tsa patsi. Ho na le bophelo bo bolelele ba bophelo bo bolelele kapa khanya ea nako e telele.

Letsoalo le se nang kelello

Khoele e tsoelang pele

Ho tjeka mat o tsoelang pele le ho chesa

Khoele ea methapo ea patsi ea mapolanka

Boitsebiso ba Lihlahisoa Ponag Laboratori:

Lisebelisoa tse ikhethang tsa liteko bakeng sa liforo-kholo tsa ho putlama le likhechana tsa ho kuta liteeeng, tse kang liteko tsa literata, liteko tsa khahlano le liteko tsa khatello. Ho latela litlhoko tsa balekane, re tla etsa lipatlisiso tsa lingoloa, ho boloka rekoto e lekola botsitso ba boleng ba nako ea nako ea. Re ka tiisa hore boleng bo ka khotsofatsa litsobotsi tsa bareki ka mokhoa oa ho qoba mathata a sa hlokahaleng ka mor'a ho rekisa.

Likhetho tsa likhetho tsa Ferp Resis Systems:

Phenolic Resin (Type P): Khetho e ntle ka ho fetisisa bakeng sa likopo tse hlokang mollo oa max le mosi oa mosi o mongata joalo ka mehono e tlase ea oli, liferisi le litefiso tsa pier le mekotla ea pier.

Vinyl Ester (Tlanya v):V Na vinyl ester ester esten e ile ea enjha ka mokhoa o hlakileng ho fana ka litšebeletso tsa kalimo ho fana ka litšebeletso tsa kalimo libakeng tse bopehileng haholo. E sebelisa tsamaiso e tsoetseng pele ea libaka e ikhethileng e isang khanyetso e ikhethang libakeng tse fapaneng tsa libaka tse nang le monko o boima o tsoang ho acidic ho ea ho ea caidic ho ea caidic. Vinyl Ester ona e boetse e fana ka boemo bo phahameng ba ho sotisa ho hanyetsa. E na le sekhahla sa 1Flame sa 1Flame sa 25 kapa ka tlase ho ea ka mokhoa o tloaelehileng oa ASTM E84 bakeng sa ho chesa. Vinyl Ester ke khetho e tsebahalang ea lits'ebetso tse ngata tsa lits'ebetso tsa ho hanana le thepa e ntle ea lijalo le litšenyehelo tse tlase tse tlase.

Isophthalic Resin (Type I): Khetho e ntle bakeng sa lits'ebetso moo lik'hemik'hale li-cumbershes tsa lik'hemik'hale li leng teng tse tloaelehileng.

Lenaneo la Lijo la Isofthalic Resin (Type F): E loketse mekhoa ea indasteri ea lijo le ea ho se hlokeheng e pepesitsoeng ho libaka tse hloekileng.

Kakaretso ea Morero oa Morero oa Orthothland Desin (Type O): Mekhoa ea Moruo ho Vinyl Baster Ester le Isophthalic band.

Epoxy Resin (Type E):Fana ka thepa ea mantlha ea ho hanyetsa le ho tepella ha mokhathala, ho nka melemo ea bahlabani e ngoe. Litsenyehelo tsa hlobo li tšoana le pe le ve, empa li theko e phahameng.

Resin Likhetho tsa Batho ba Utloang:

| Rala mofuta oa | Khetho ea Resin | Thepa | Khanyetso ea Chemtical | Mollo oa Mollo (Astm e84) | Lihlahisoa | Mebala ea linaha | Max ℃ Temp |

| Thaepa p | Phenolic | Mosi o tlase le khanyetso e phahameng ea mollo | Hantle haholo | Sehlopha sa 1, 5 kapa ka tlase | E entsoe le ho putlama | Mebala ea linaha | 150 ℃ |

| Tlanya v | Vinyl Ester | Ho hanyetsa ha ho tsitsipana le ho tsitsipana le mollo | E ntle haholo | Sehlopha sa 1, 25 kapa ka tlase ho | E entsoe le ho putlama | Mebala ea linaha | 95 ℃ |

| Thaepa i | Isophthalic polyester | Liindasteri tsa Sehlopha sa Liindasteri le Mollo oa Mollo | Hantle haholo | Sehlopha sa 1, 25 kapa ka tlase ho | E entsoe le ho putlama | Mebala ea linaha | 85 ℃ |

| Tlanya O | Ortho | Ho hanela ho hanyetsa le ho loantšana le ho ikhula le ho khutlisa mollo | Tloaelehileng | Sehlopha sa 1, 25 kapa ka tlase ho | E entsoe le ho putlama | Mebala ea linaha | 85 ℃ |

| Tlanya f | Isophthalic polyester | Ho hanela ho hanela lijo tsa lijo le ho khutlisa mollo | Hantle haholo | Sehlopha sa 2, 75 kapa ka tlase | E thehiloe | Sootho | 85 ℃ |

| Tlanya e | EPOXY | Khanyetso e mpe ea lijalo le mollo oa mollo | E ntle haholo | Sehlopha sa 1, 25 kapa ka tlase ho | E tšehelitsoe | Mebala ea linaha | 180 ℃ |

Ho khetha mofuta o nepahetseng oa libaka o bohlokoa ho fana ka khanyetso ea ho itlhophisa le ho netefatsa ho ts'epahala ha nako ea bophelo le ts'ebetso ea ho itlopa joala. Haeba u sa tsebe bonnete ba hore na ke ntho ea mofuta ofe e lumellanang le litlhoko tsa hau tsa kopo, ikutloe u lokolohile ho ikopanya le rona.

Ho latela lits'ebetso, li-harails li ka sebelisoa tikolohong e fapaneng:

• Towers towers • Litharollo tsa hau tsa ho futhumatsa • Litlhohonolofatso tse kholo

• Matšoao a amanang le ho jala - Matšoao a lehloa • Marine / Offshore

• Li-Rails tsa matsoho • litepisi

• lik'hemik'hale • pulp le pampiri • meepo

• Telecommunication • Temo ea matsoho • Lisebelisoa tsa letsoho

• Motlakase • Metsi le leqeba • Likopo tsa Tloaelo

• Lipalangwang / Likoloi

• Boithabiso & porpark

• Kaho ea bab'eno / Bolulo

Dikarolo tsa dikarollo tsa maiketsetso a poljo: