Frull Putrri o sentse se Tumellanong ea STRITANT / Checant Antistant

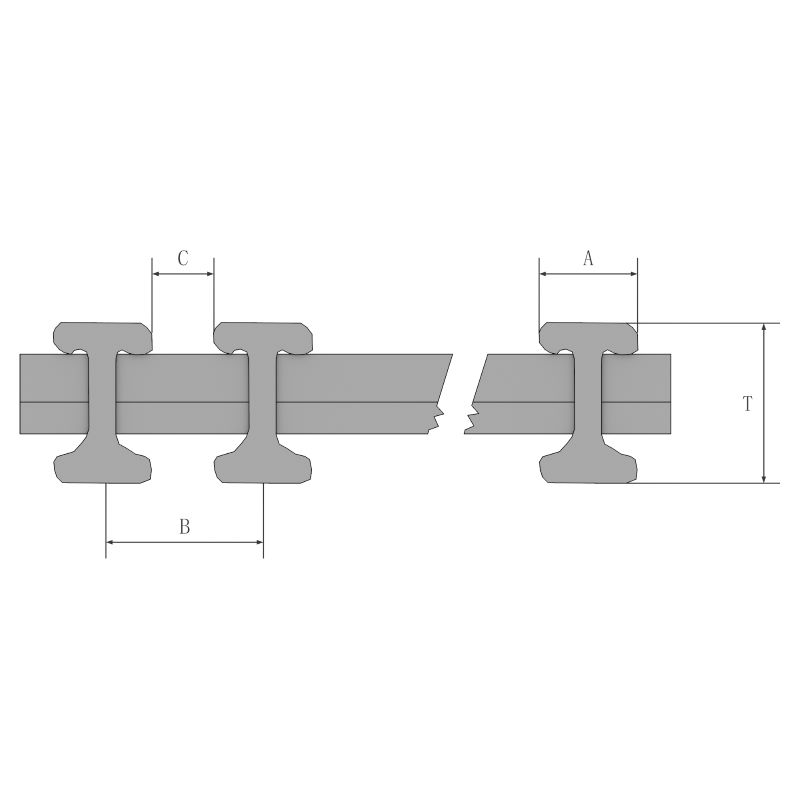

Likarolo tsa pontšo e entsoeng ka polping e kopaneng:

| I-5010 | 50 | 15 | 25 | 10 | 40 | 28.5 |

| I-5015 | 50 | 15 | 30 | 15 | 50 | 24.2 |

| I-5023 | 50 | 15 | 38 | 23 | 60 | 20.1 |

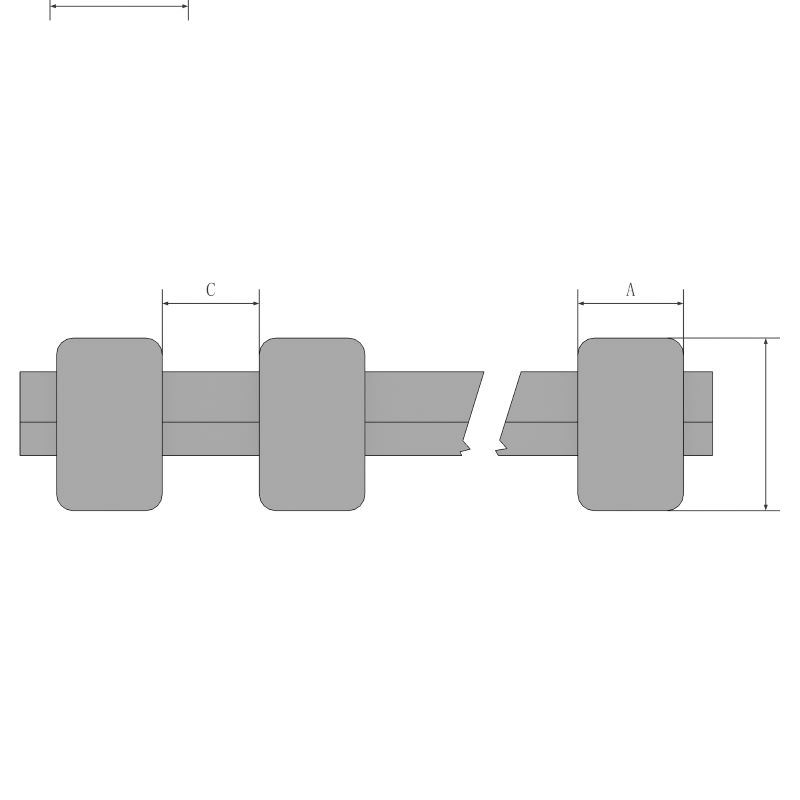

| T-2510 | 25 | 38 | 43.4 | 5.4 | 12 | 15.6 |

| T-2515 | 25 | 38 | 50.8 | 9.5 | 18 | 13.9 |

| T-2520 | 25 | 38 | 50.8 | 12.7 | 25 | 13.6 |

| T-2530 | 25 | 38 | 61 | 19.7 | 33 | 11.2 |

| T-3810 | 38 | 38 | 43.3 | 5.2 | 12 | 19.6 |

| T-3815 | 38 | 38 | 50.8 | 12.7 | 25 | 16.7 |

| T-3820 | 38 | 38 | 61 | 23 | 38 | 14.3 |

| T-5010 | 50 | 25.4 | 38.1 | 12.7 | 33 | 21.8 |

| T-5015 | 50 | 25.4 | 50.8 | 25.4 | 50 | 17.4 |

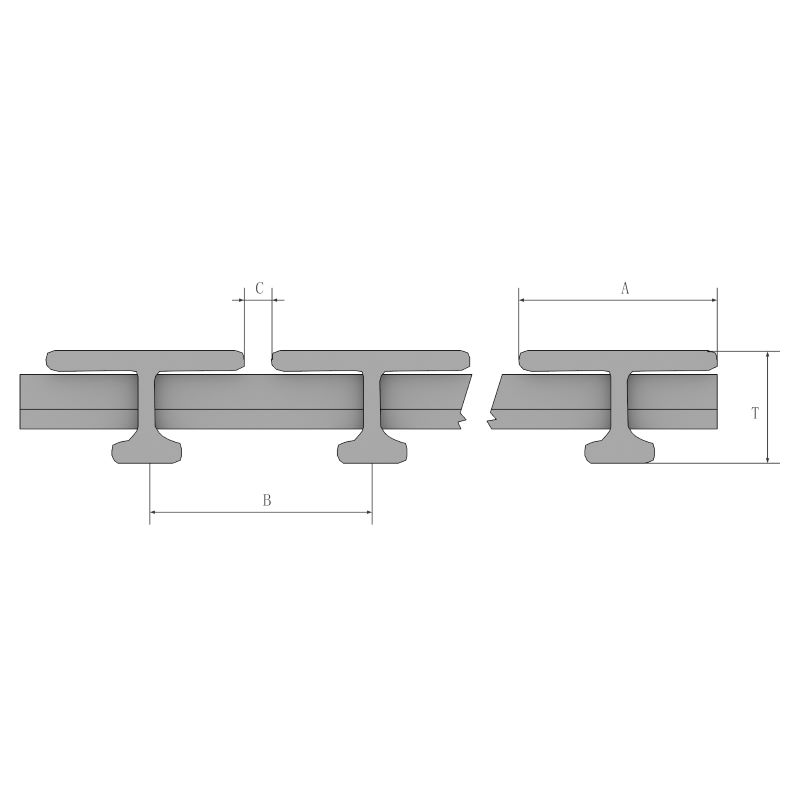

| H-5010 | 50 | 15 | 10 | 10 | 40 | 63 |

| H-5015 | 50 | 15 | 15 | 15 | 50 | 52.3 |

| H-5020 | 50 | 15 | 23 | 23 | 60 | 43.6 |

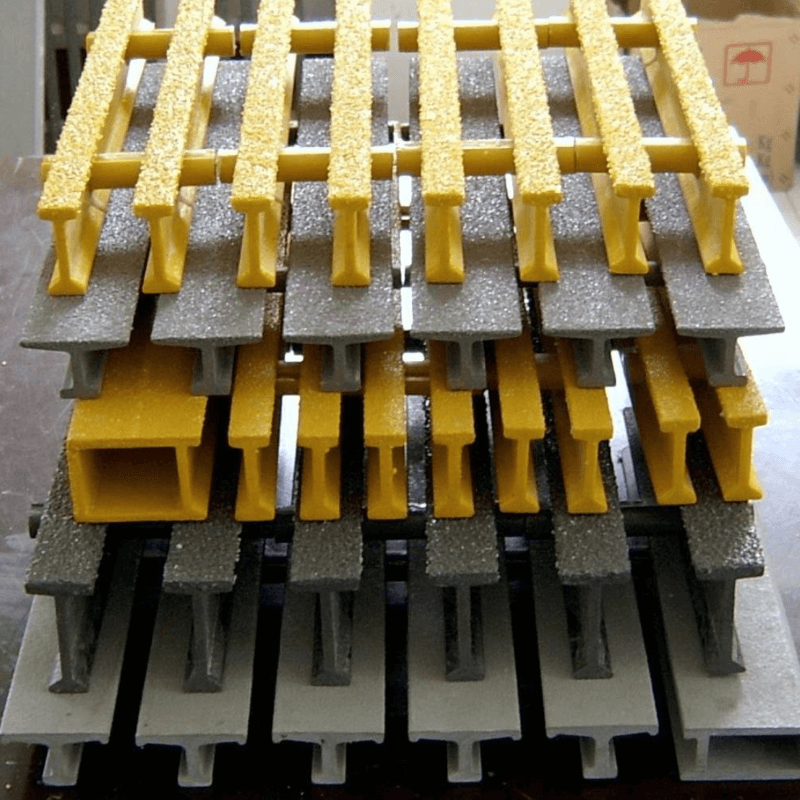

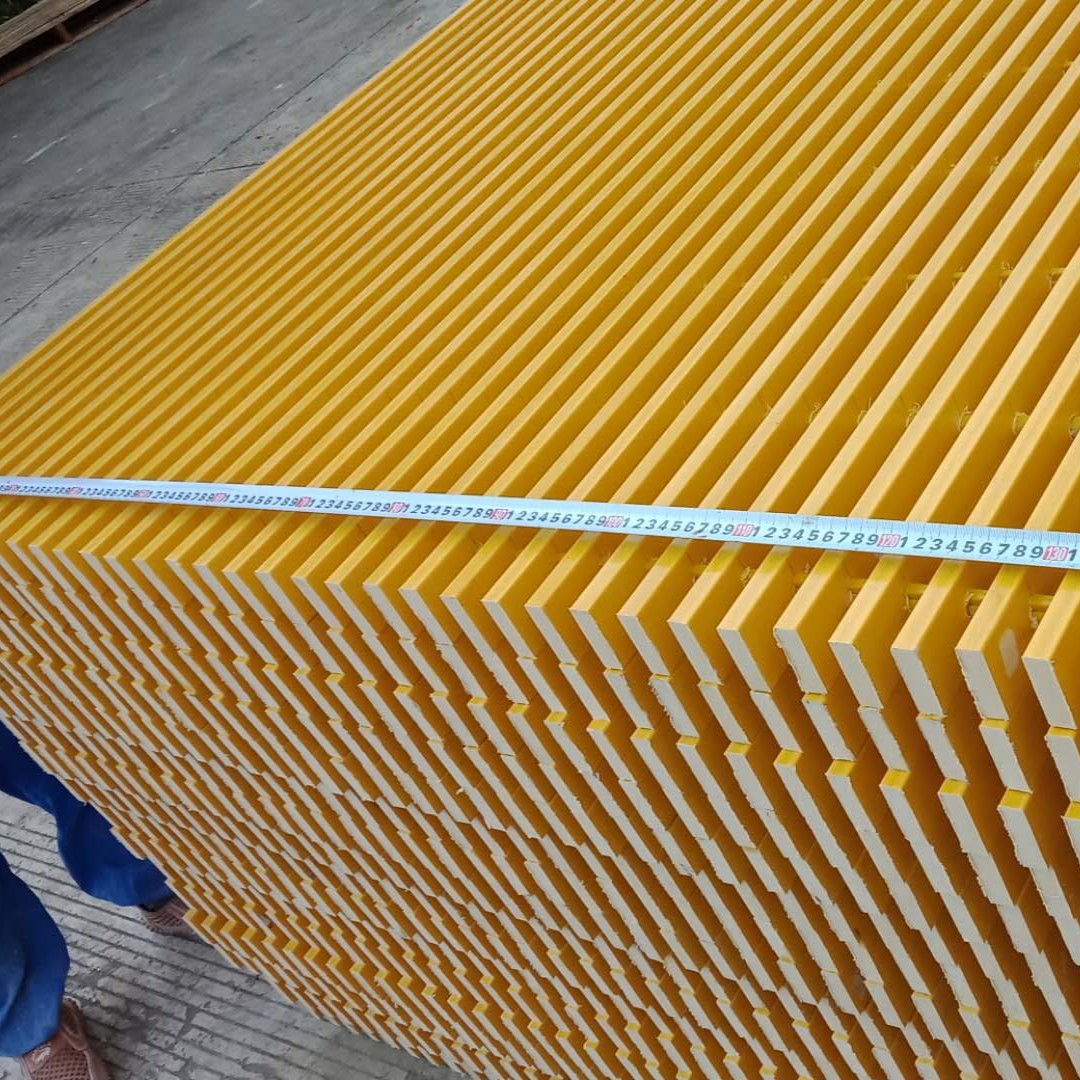

| Mofuta oa ho chesoa ka letsoho | Bophahamo (limilimithara) | Bophara bo holimo (limilimithara) | Sebaka pakeng tsa (mm) | Boraro ba Clearance (mm) | Sebaka se bulehileng (%) | Boima ba boima ba boima ba kg / ㎡ |

| I-2510 | 25 | 15 | 25 | 10 | 40 | 17.8 |

| I-2515 | 25 | 15 | 30 | 15 | 50 | 15.2 |

| I-2523 | 25 | 15 | 38 | 23 | 60 | 12.2 |

| I-3810 | 38 | 15 | 25 | 10 | 40 | 22 |

| I-3815 | 38 | 15 | 30 | 15 | 50 | 19.1 |

| I-3823 | 38 | 15 | 38 | 23 | 60 | 16.2 |

| I-3010 | 30 | 15 | 25 | 10 | 40 | 19.1 |

| I-3015 | 30 | 15 | 30 | 15 | 50 | 16.1 |

| I-3023 | 30 | 15 | 38 | 23 | 60 | 13.1 |

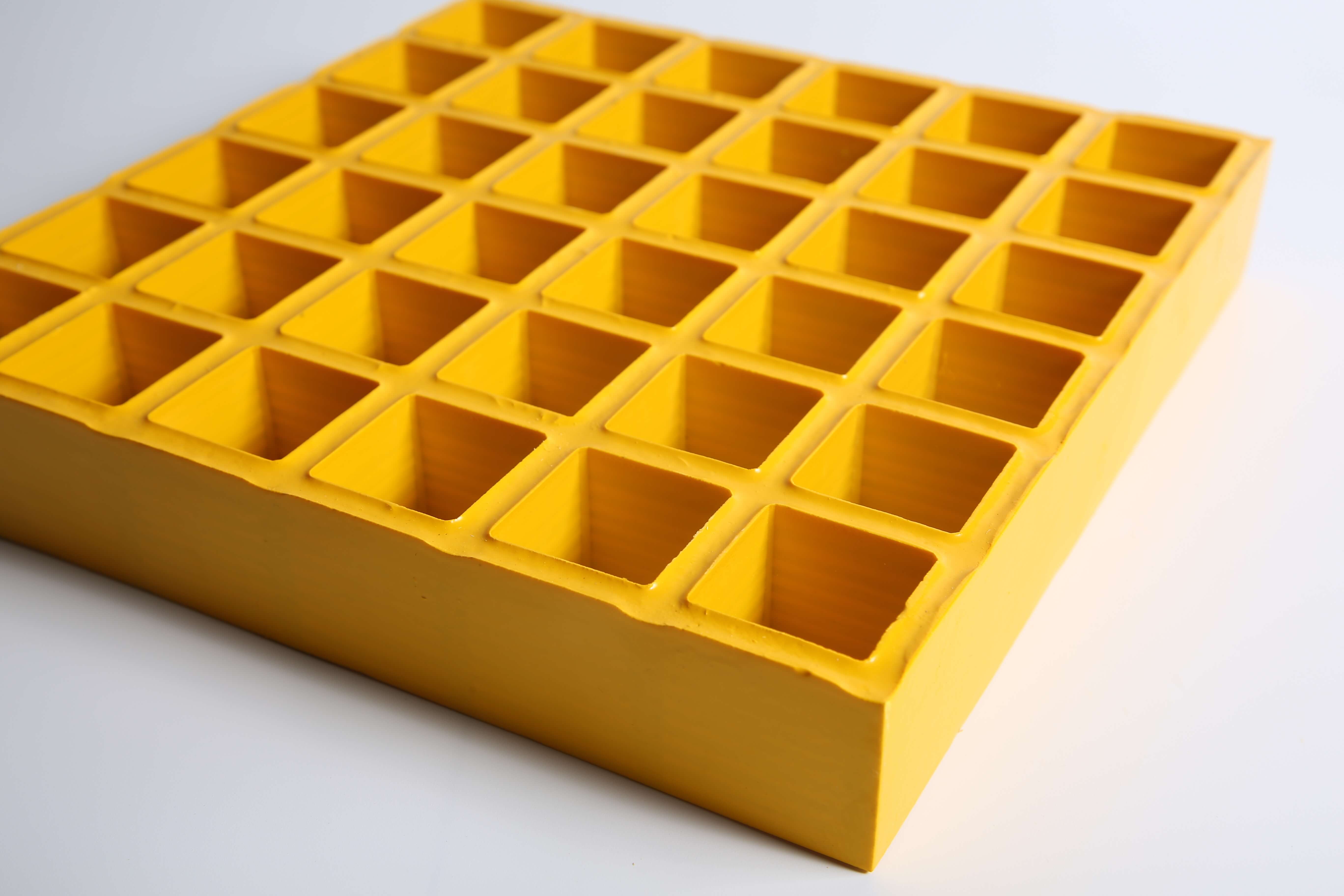

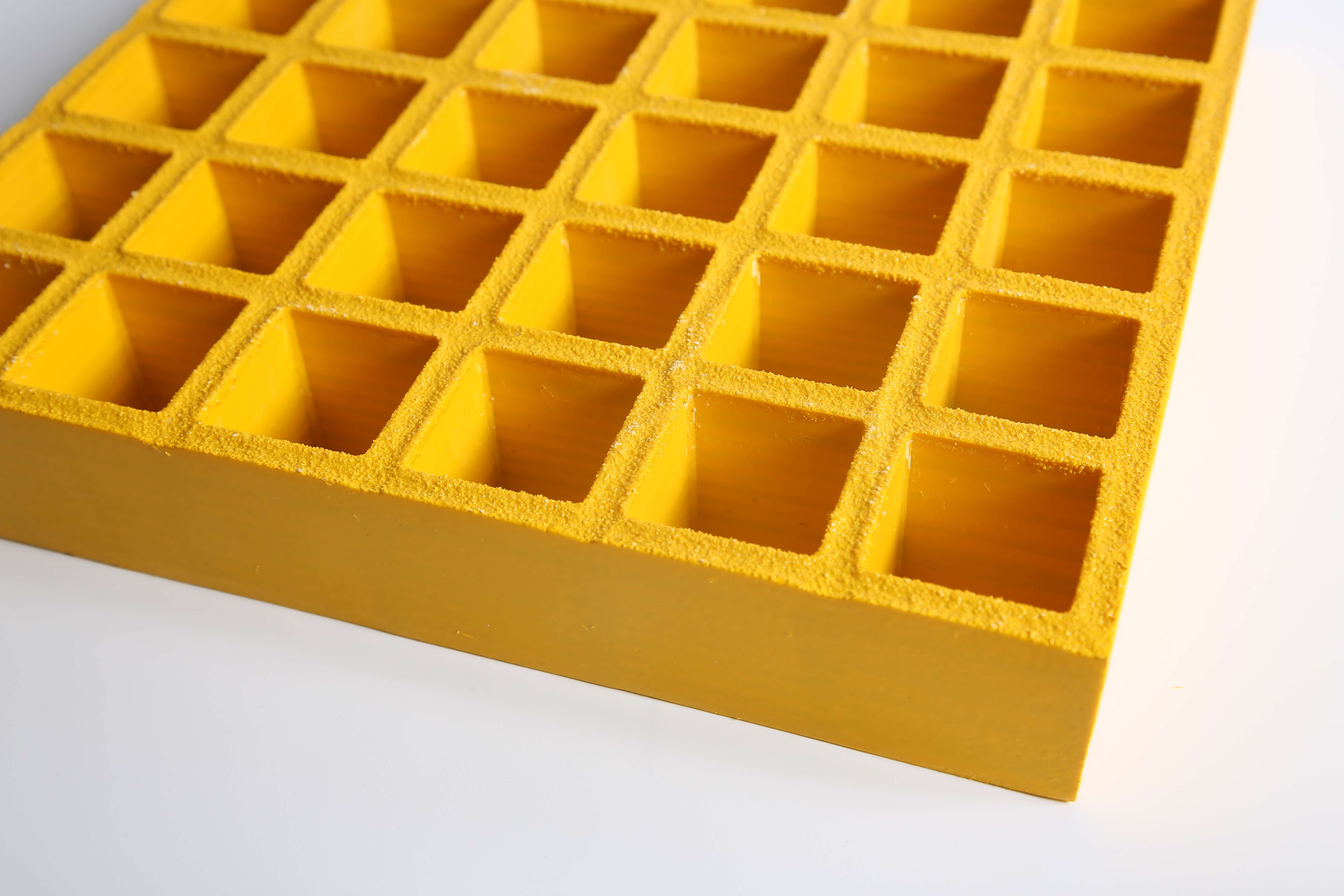

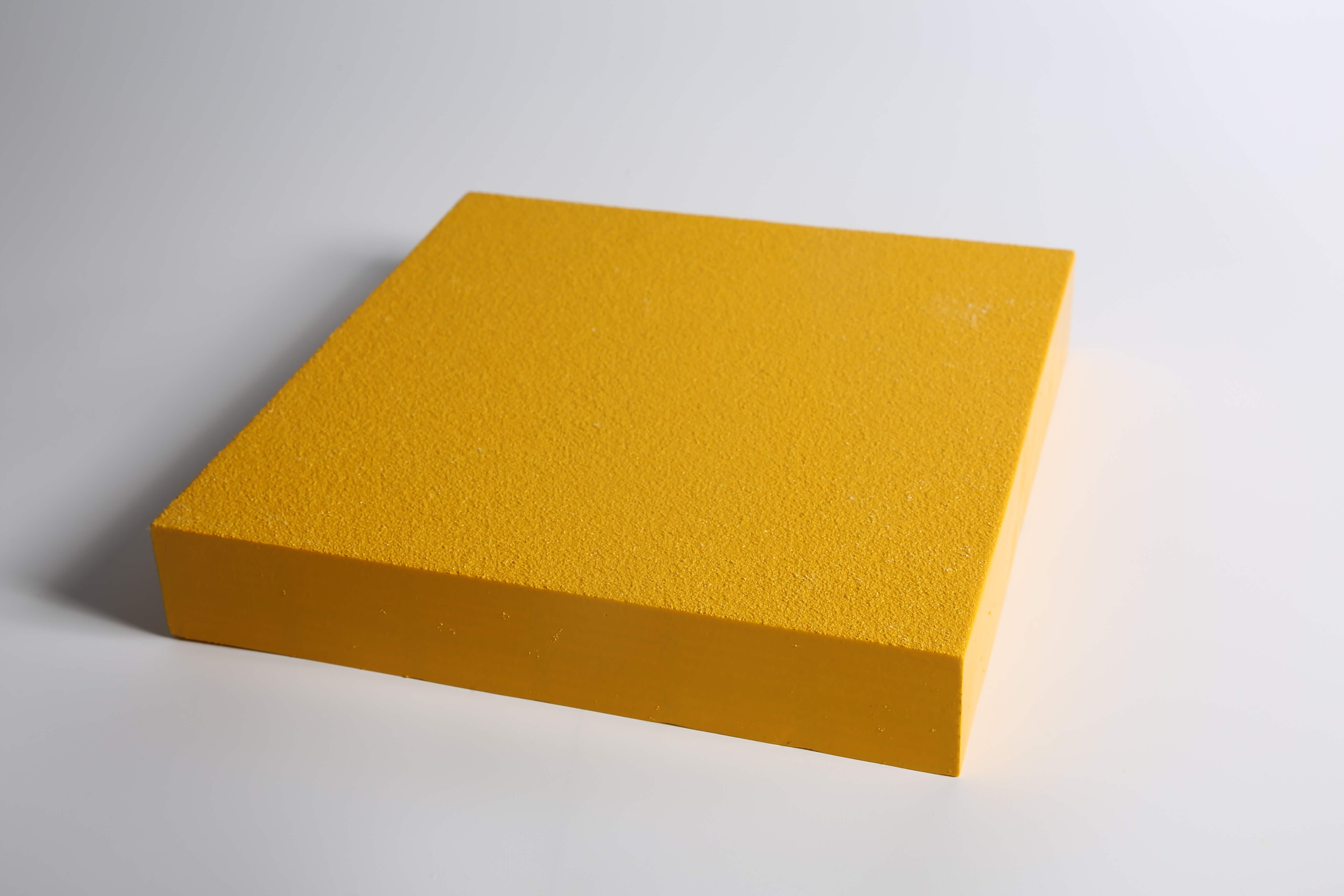

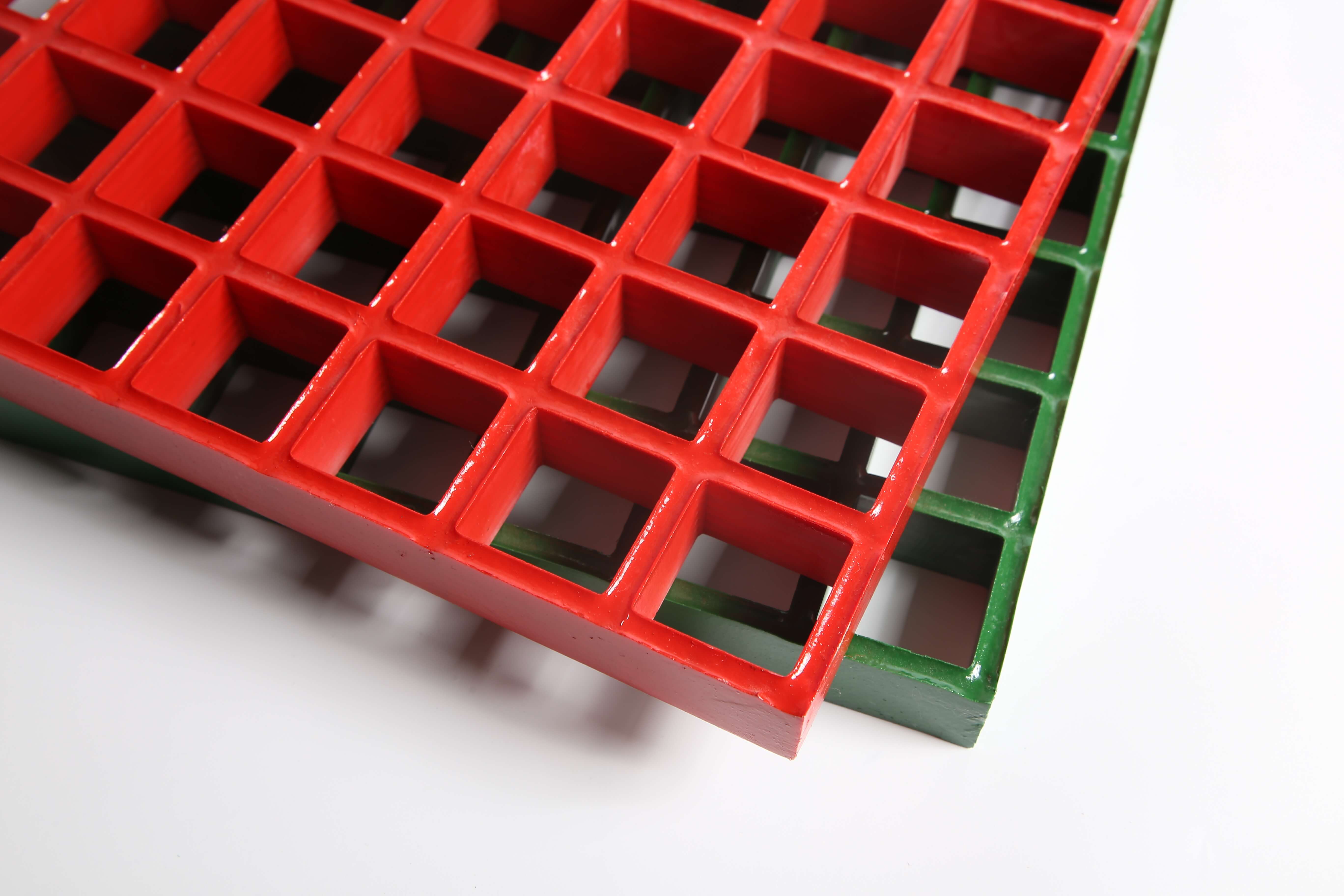

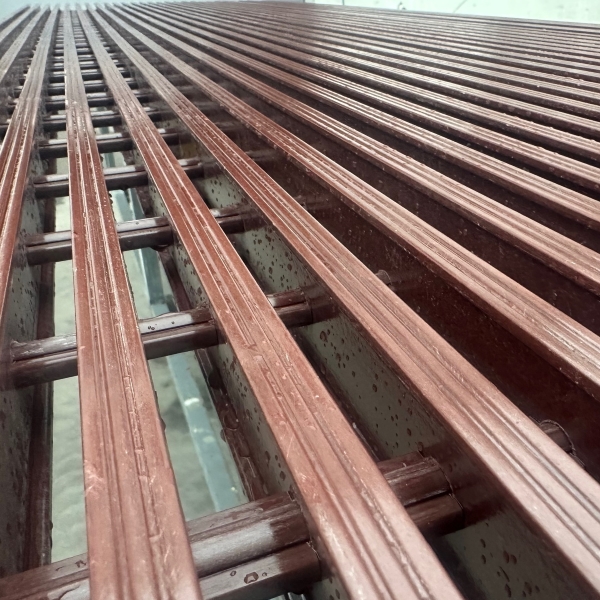

Sinograte @ Frep Boded Grating:

•Leseli

• Tlhahlobo

• khanyetso ea lik'hemik'hale

• Mollo oa Mollo

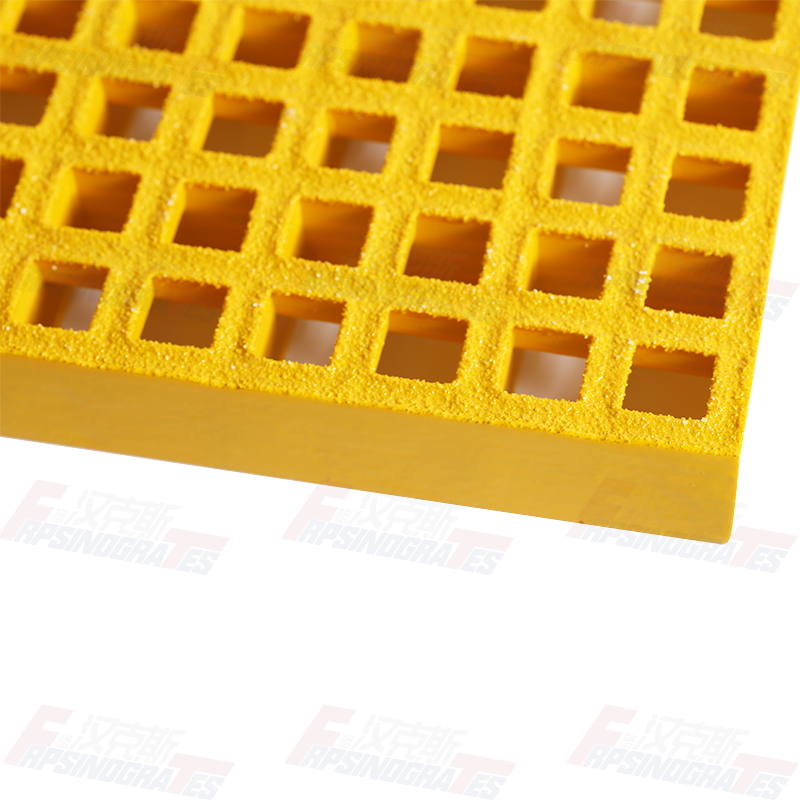

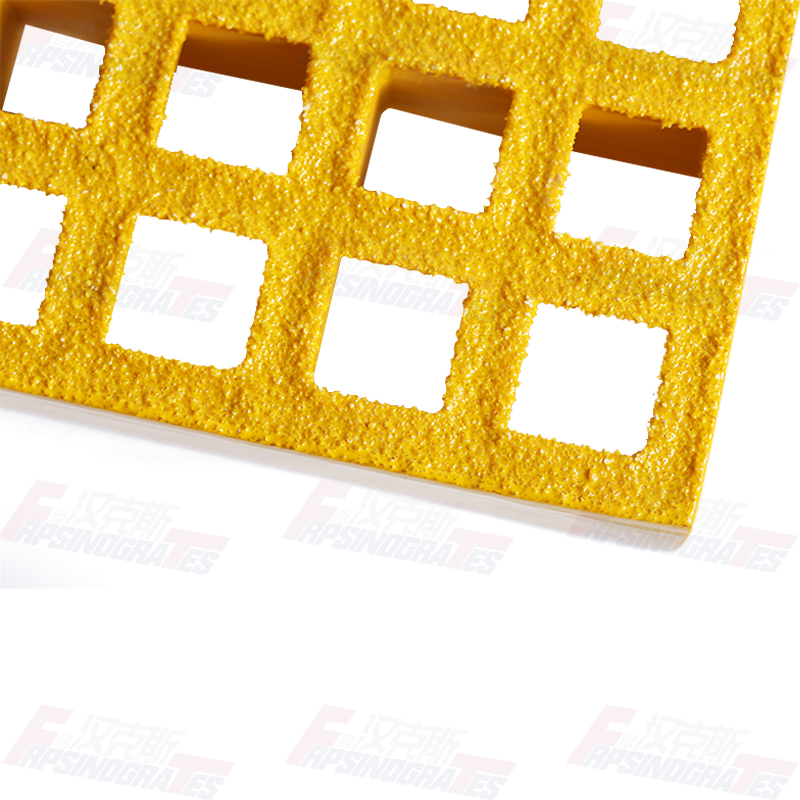

• Libaka tsa Anti-Slip

• e bonolo bakeng sa ho kenya

• litšenyehelo tse tlase tsa tokiso

• Ts'ireletso ea UV

• Matla a mabeli a matla

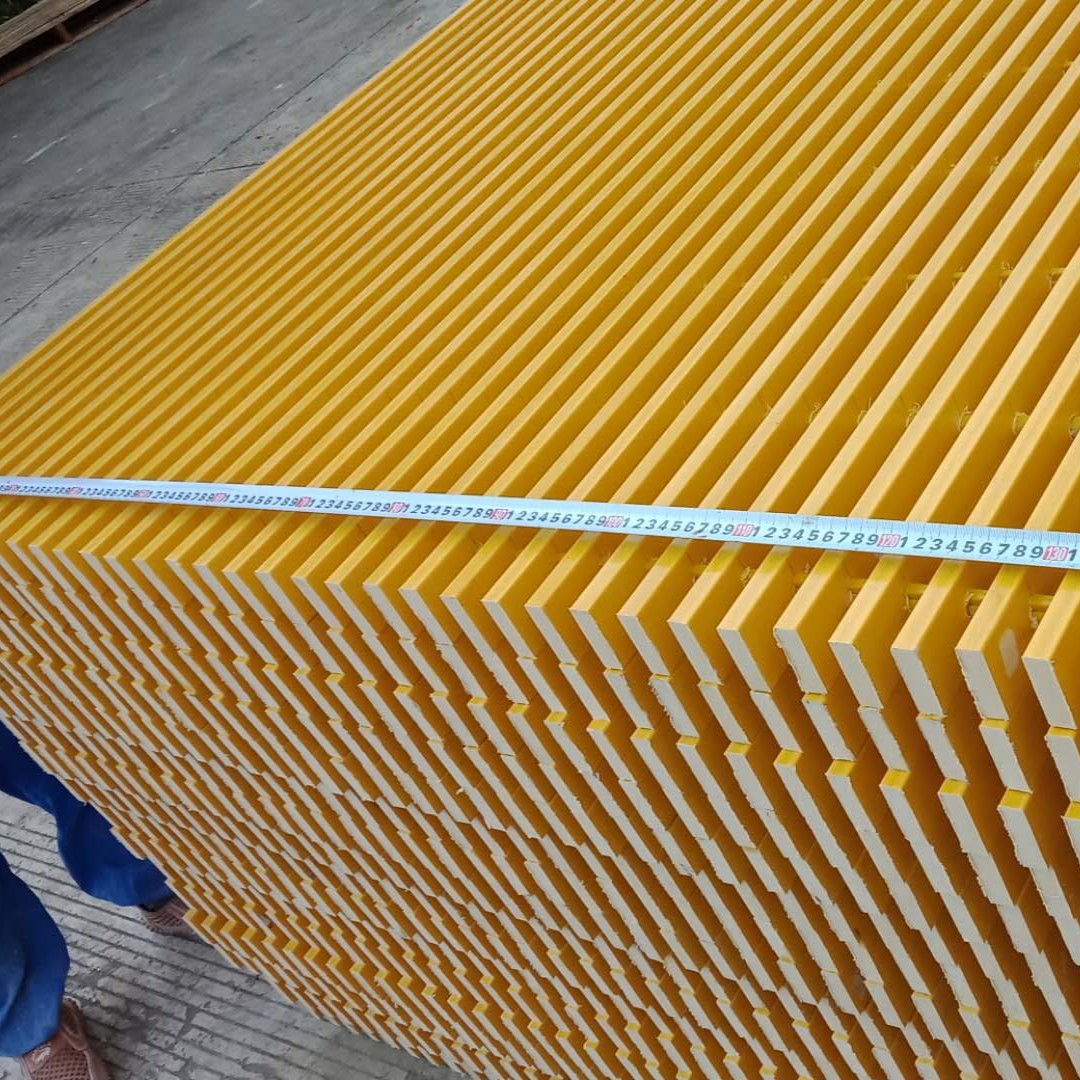

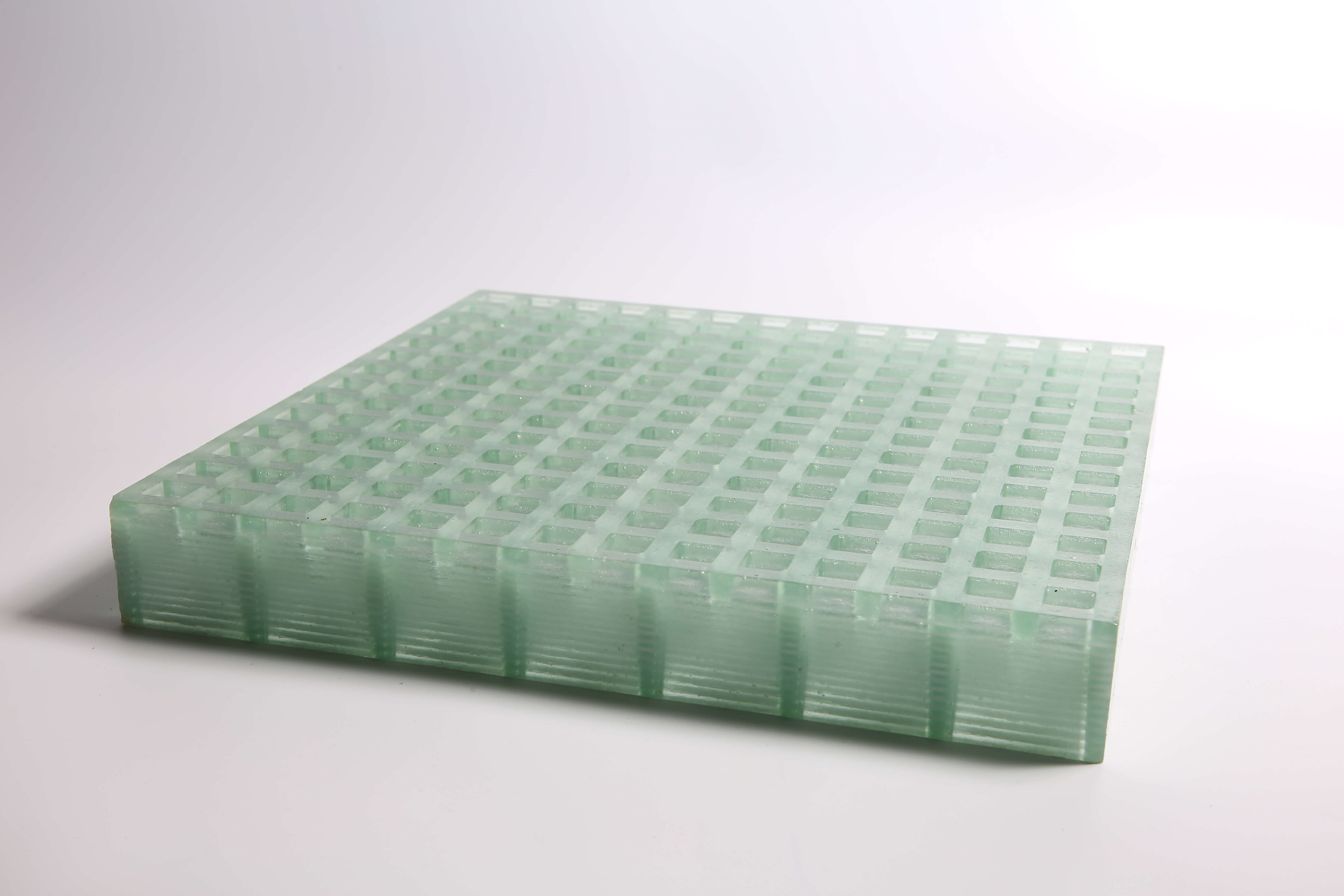

Ts'ebetso ea pollusion ke mokhoa oa ho etsa tlhahiso bakeng sa ho hlahisa meeli e tsoelang pele ea profiles e matlafalitsoeng e nang le likarolo tse sieo khafetsa. Lisebelisoa tse tala ke motsoako oa ho boloka metsi Ts'ebetso ena e kenyelletsa ho hula lisebelisoa tsena tse tala (ho fapana le ho sutumetsa, joalo ka ha ho etsoa letlotlo) ka sesebelisoa se futhumetseng se sebelisang sesebelisoa se ntseng se hula.

Lisebelisoa tse matlafalitsoeng ke lifoto tse tsoelang pele tse kang lipere tsa matts tsa fiberglass le li-doffs tsa liroboto tsa fiberglass. Ha litšitiso li ntse li tšoareloa ka motsoako oa resitha ("o mongobo ke ho phomola, a huloa, ho thehoa boemo ba hae bo lumellanang le sebopeho sa mafu.

Mabenkele a kenyelletsa polokelo ea Orthophthalic, Isophthalic Ren, Vinyl Ren, EPoxy Ren, EPoxy Ren, EPonalic Resin, EPoxS E na le boholo ba 70% le bonyane ba 65% ea li-fiberglass tse li silafatsang le tsa pelo tse nonneng tsa moea. Kahoo, ka ho lelekisa khatello ea moea le ho hanyetsa hoa thuso ea leqathatso.

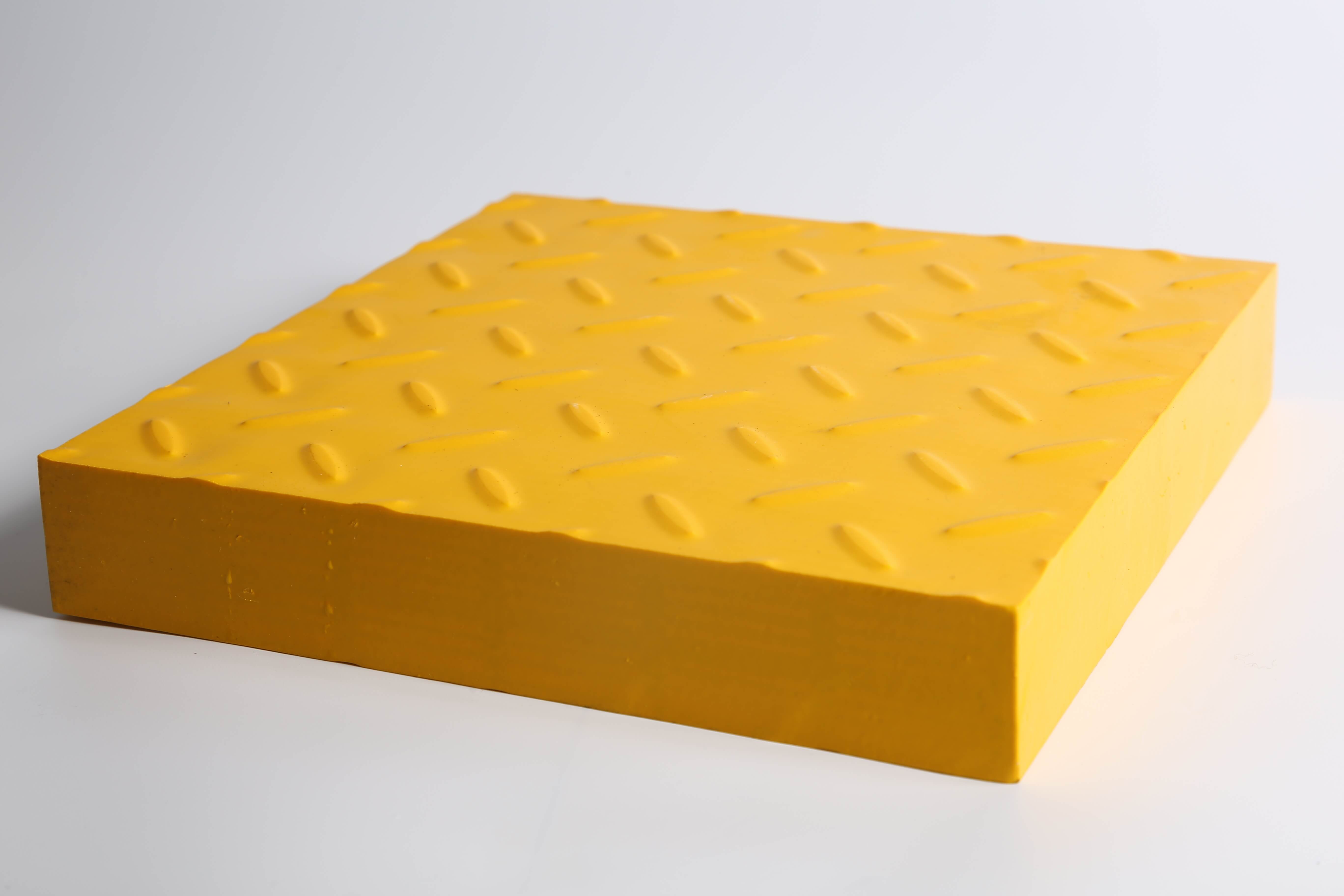

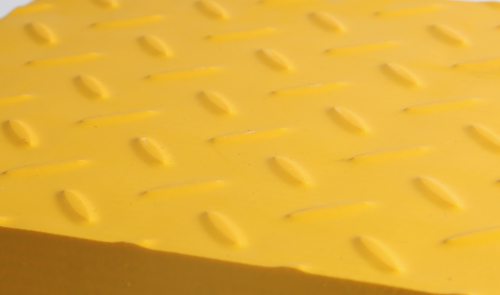

Phekolo ea libaka tse seng tse sa thellang: Ho ikhula ho tla bolokoa ka lesela la Quartz ka holim'a libaka tse holimo. U ka kopa libaka tse sa thekeseleng ho latela merero ea hau.

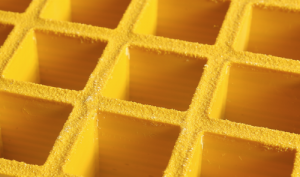

Li-biberglass grust grucs grust:

Libaka tse holimo tsa Crescent: Ha ho na quarter e ka bang mahlakore a khang ea concave kapa a mathule a marang-rang

Li-quartz tsa quartz

Boitsebiso ba Lihlahisoa Ponag Laboratori:

Lisebelisoa tse ikhethang tsa liteko bakeng sa liforo-kholo tsa ho putlama le likhechana tsa ho kuta liteeeng, tse kang liteko tsa literata, liteko tsa khahlano le liteko tsa khatello. Ho latela litlhoko tsa balekane, re tla etsa lipatlisiso tsa lingoloa, ho boloka rekoto e lekola botsitso ba boleng ba nako ea nako ea. Re ka tiisa hore boleng bo ka khotsofatsa litsobotsi tsa bareki ka mokhoa oa ho qoba mathata a sa hlokahaleng ka mor'a ho rekisa.

Likhetho tsa likhetho tsa Ferp Resis Systems:

Phenolic Resin (Type P): Khetho e ntle ka ho fetisisa bakeng sa likopo tse hlokang mollo oa max le mosi oa mosi o mongata joalo ka mehono e tlase ea oli, liferisi le litefiso tsa pier le mekotla ea pier.

Vinyl Ester (Tlanya v): E mamella tikoloho e thata ea khōko e sebelisoang ho kalafo ea lik'hemik'hale, le lijalo tse fumanoang.

Isophthalic Resin (Type I): Khetho e ntle bakeng sa lits'ebetso moo lik'hemik'hale li-cumbershes tsa lik'hemik'hale li leng teng tse tloaelehileng.

Lenaneo la Lijo la Isofthalic Resin (Type F): E loketse mekhoa ea indasteri ea lijo le ea ho se hlokeheng e pepesitsoeng ho libaka tse hloekileng.

Kakaretso ea Morero oa Morero oa Orthothland Desin (Type O): Mekhoa ea Moruo ho Vinyl Baster Ester le Isophthalic band.

Epoxy Resin (Type E):Fana ka thepa ea mantlha ea ho hanyetsa le ho tepella ha mokhathala, ho nka melemo ea bahlabani e ngoe. Litsenyehelo tsa hlobo li tšoana le pe le ve, empa li theko e phahameng.

Resin Likhetho tsa Batho ba Utloang:

| Rala mofuta oa | Khetho ea Resin | Thepa | Khanyetso ea Chemtical | Mollo oa Mollo (Astm e84) | Lihlahisoa | Mebala ea linaha | Max ℃ Temp |

| Thaepa p | Phenolic | Mosi o tlase le khanyetso e phahameng ea mollo | Hantle haholo | Sehlopha sa 1, 5 kapa ka tlase | E entsoe le ho putlama | Mebala ea linaha | 150 ℃ |

| Tlanya v | Vinyl Ester | Ho hanyetsa ha ho tsitsipana le ho tsitsipana le mollo | E ntle haholo | Sehlopha sa 1, 25 kapa ka tlase ho | E entsoe le ho putlama | Mebala ea linaha | 95 ℃ |

| Thaepa i | Isophthalic polyester | Liindasteri tsa Sehlopha sa Liindasteri le Mollo oa Mollo | Hantle haholo | Sehlopha sa 1, 25 kapa ka tlase ho | E entsoe le ho putlama | Mebala ea linaha | 85 ℃ |

| Tlanya O | Ortho | Ho hanela ho hanyetsa le ho loantšana le ho ikhula le ho khutlisa mollo | Tloaelehileng | Sehlopha sa 1, 25 kapa ka tlase ho | E entsoe le ho putlama | Mebala ea linaha | 85 ℃ |

| Tlanya f | Isophthalic polyester | Ho hanela ho hanela lijo tsa lijo le ho khutlisa mollo | Hantle haholo | Sehlopha sa 2, 75 kapa ka tlase | E thehiloe | Sootho | 85 ℃ |

| Tlanya e | EPOXY | Khanyetso e mpe ea lijalo le mollo oa mollo | E ntle haholo | Sehlopha sa 1, 25 kapa ka tlase ho | E tšehelitsoe | Mebala ea linaha | 180 ℃ |

Mebala ea linahaHo latela tikoloho e fapaneng le likopo, tse khethiloeng tse fapaneng, re boetse re ka fa likeletso!